Extraction and purification method of daptomycin

A daptomycin and purification method technology, which is applied in the field of extraction and purification of daptomycin, can solve the problems of difficult industrialization of the purification process and complex extraction and purification process of daptomycin, and achieve easy industrial production and obvious decolorization effect , The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: the enrichment adsorption contrast test of daptomycin:

[0048] The resins are macroporous adsorption resin HZ818 from Shanghai Huazhen Technology Co., Ltd.

[0049] 1) The method described in the literature "Chinese Journal of Antibiotics, Volume 33, Issue 2, February 2008" "Study on Adsorption and Separation of Daptomycin Fermentation Broth by Macroporous Resin" was used for the test.

[0050] Resin pretreatment: fully soak the resin with acetone to remove pigment and impurities, wash with distilled water until the washing solution is not muddy after adding acetone. Then soak in 1mol / L HCl solution 4 times the volume of the resin for 3 hours to remove alkaline substances, and wash with distilled water until neutral. Soak in 1mol / L NaOH solution 4 times the volume of the resin for 3 hours to remove acidic substances, wash until neutral and set aside.

[0051] Take 200ml of daptomycin fermentation filtrate, containing 139mg of daptomycin, and 20ml of tre...

Embodiment 2

[0058] Embodiment 2, crude extraction, refining

[0059] 1), rough extraction:

[0060] A. Acidic column chromatography: 40 liters of concentrated solution, 353 grams, 70% purity, dark brown color, the former impurity RRT1 is 17.14%, adjust the pH to 2 with formic acid; resin After the PRP512 column, it was eluted with 40% methanol concentration aqueous solution with a pH value of 2.5; collected the eluted fraction, adjusted the pH to 6, concentrated 20 liters, 230g, 85% purity, brown color, and the former impurity RRT1 is 5.24%, and the yield is 65.4%.

[0061] B. Neutral column chromatography: 20 liters of concentrated solution, adjust pH to about 6 with sodium hydroxide, add about 3% sodium chloride; elute with 20% methanol after being applied to the resin PRP512 column, and collect the eluted fraction; The collected fractions were adjusted to a pH of about 6 with formic acid; concentrated, 5 liters; light brown in color, 144 g, with a purity of 88%, the former impurity RR...

Embodiment 3

[0066] Embodiment 3, crude extraction, refining

[0067] 1), rough extraction:

[0068] A. Acidic column chromatography: 400 liters of concentrated solution, 3500 grams, 68.5% purity, dark brown color, 12.05% for the former impurity RRT1, adjust the pH to 4 with acetic acid; After the column, it was eluted with 40% ethanol concentration aqueous solution with a pH value of 2.7; collected the eluted fraction, adjusted the pH to 8, concentrated 100 liters, 2180g, 83% purity, brown color, and the former impurity RRT1 is 6.85%, and the yield is 62.3%.

[0069] B. Neutral column chromatography: concentrate 100 liters, adjust the pH to about 6 with potassium hydroxide, add about 3% sodium chloride; elute with 30% methanol after being applied to the C8 column, and collect the eluted fraction; collect The eluted fraction was adjusted to pH 6 with formic acid; concentrated, 10 liters; light brown in color, 1405 g, purity 90%, the former impurity RRT1 was 3.09%.

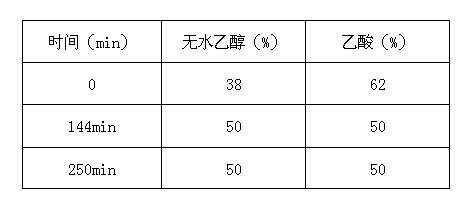

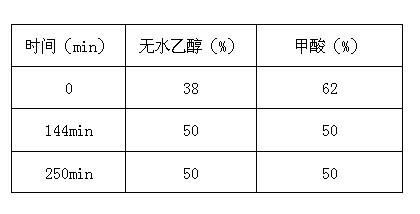

[0070] 2), refined: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com