Preparation and application of water-borne polyurethane polyacrylate compound emulsion

A polyacrylate emulsion and water-based polyurethane technology, applied in the polymer field, can solve the problems of complex process, unenvironmental protection and high cost, achieve good application prospects and overcome the effect of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

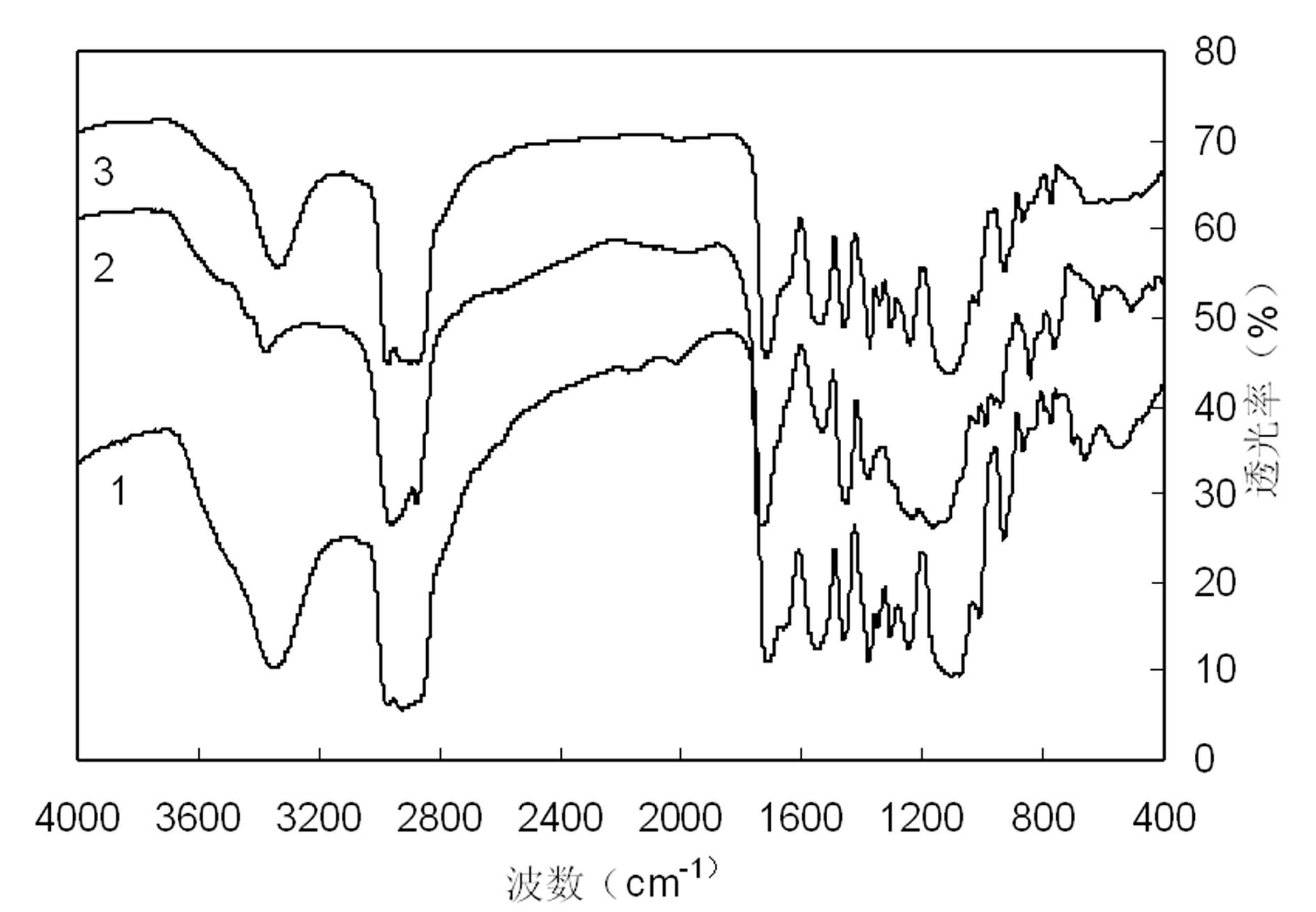

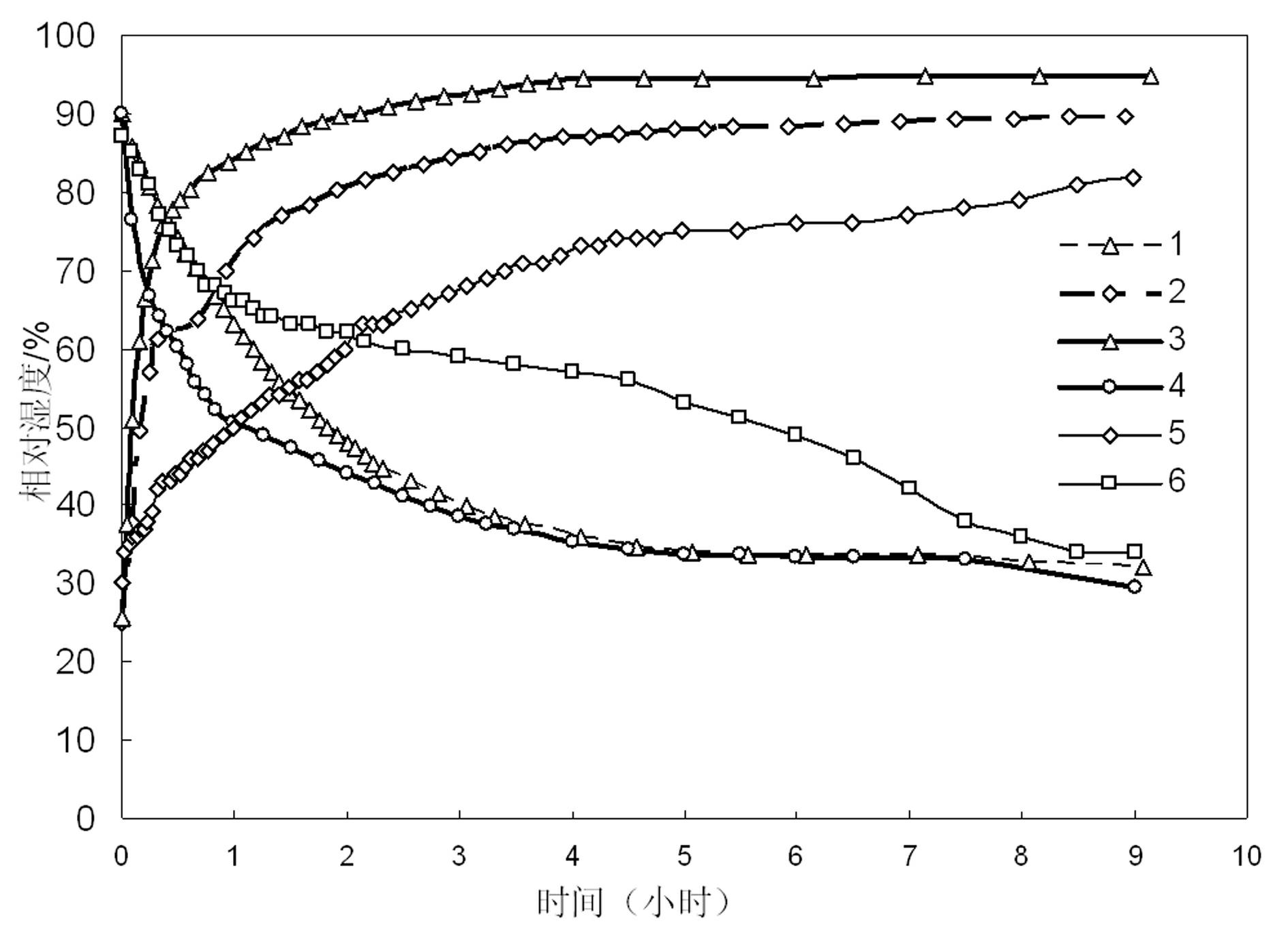

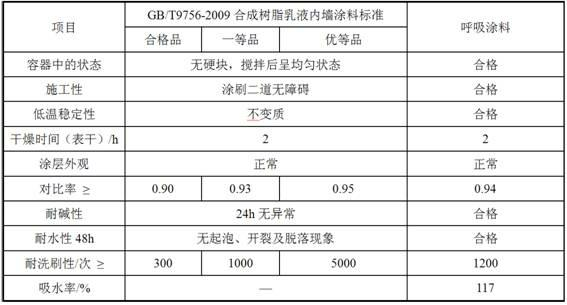

[0047] (1) Preparation of waterborne polyurethane polyacrylate composite emulsion

[0048] Take 1g of polypropylene glycol, 20g of isophorone diisocyanate, and 0.1g of 2,2-dimethylolpropionic acid into a four-neck flask, dissolve with 12g of acetone; heat up to 100°C to start the reaction, react for 80 minutes, and cool down to 30°C ℃, add 0.1g of triethylamine, neutralize for 30 minutes; add 15g of distilled water, stir at high speed (120r / min) and disperse for 30 minutes to obtain a water-based polyurethane emulsion.

[0049] Take another four-necked flask and add 0.1g of compound emulsifier (0.05g of sodium lauryl sulfate, Tween -20 0.05g), distilled water 20g, heat up to 60°C, add dropwise 20g of methyl methacrylate, 1g of acrylic acid, 50g of butyl acrylate, 5g of diacetone acrylamide, and 0.1g of ammonium persulfate as an initiator; Hours, a mixed solution was obtained; the temperature was lowered to 30°C, and the pH value was adjusted to 8 with ammonia water with a mas...

Embodiment 2

[0055] (1) Preparation of waterborne polyurethane polyacrylate composite emulsion

[0056] Weigh 50g of polypropylene glycol, 20g of isophorone diisocyanate, and 0.1g of 2,2-dimethylolpropionic acid into a four-neck flask, dissolve with 1g of acetone; heat up to 100°C to start the reaction, and react for 240 minutes; then cool down At 30°C, add 0.1g of triethylamine and react for 30 minutes; add 5g of distilled water and disperse for 30 minutes with high-speed stirring (300r / min) to obtain a water-based polyurethane emulsion.

[0057] Take another four-necked flask, add compound emulsifier 0.1g (sodium lauryl sulfate 0.02g, Tween -20 0.08g), distilled water 1g, heat up to 60°C, dropwise add 20g of methyl methacrylate, 15g of acrylic acid, 50g of butyl acrylate, 5g of diacetone acrylamide, 0.1g of initiator potassium persulfate, keep warm for 1 Hours, a mixed solution was obtained; the temperature was lowered to 30°C, and the pH value was adjusted to 7 with 5% ammonia water by...

Embodiment 3

[0063] (1) Preparation of waterborne polyurethane polyacrylate composite emulsion

[0064] Weigh 40g of polypropylene glycol, 20g of isophorone diisocyanate, and 12g of 2,2-dimethylolpropionic acid, add them into a four-necked flask, and dissolve them with 15g of acetone; heat up to 40°C and react for 100 minutes; cool down to 30°C , add 0.1g of triethylamine, neutralize and react for 30 minutes; add 30g of distilled water, stir at high speed (300r / min) and disperse for 5 minutes to obtain a water-based polyurethane emulsion.

[0065] Get another four-necked flask, add compound emulsifier 20g (sodium lauryl sulfate 5g, Tween -20 15g), distilled water 50g, heat up to 60°C, start dropwise adding 1g of methyl methacrylate, 20g of acrylic acid, 50g of butyl acrylate, 5g of diacetone acrylamide, 0.1g of initiator ammonium persulfate, and keep warm for 3 Hours, a mixed solution is obtained; the temperature is lowered to 30°C, and the pH value is adjusted to 10 with 10% by mass perc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com