Precipitated iron catalyst for catalyzing Fischer-Tropsch synthetic reaction and preparation method thereof

A technology of catalyst and troposynthetic synthesis, which is applied in the field of precipitated iron catalyst and its preparation, can solve the problems of poor stability of precipitated iron catalyst, achieve the effects of increasing long-term operation stability, increasing physical stability and mechanical strength, and improving stable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] According to another aspect of the present invention, a method for preparing any one of the above-mentioned precipitated iron catalysts is provided. The method comprises the following steps: preparing ferric nitrate solution, copper nitrate solution and ferrous sulfate solution, mixing them to obtain a mixed salt solution; adjusting the pH of the mixed salt solution and stirring to obtain a precipitation slurry, separating the precipitation slurry to obtain a filter cake; Adding potassium ion-containing solution and / or potassium-containing silica sol, silica sol and magnesium-aluminum sol to the cake or adding potassium-containing silica sol and magnesium-aluminum sol to the filter cake, stirring to obtain a catalyst slurry; and drying the catalyst slurry , roasted to obtain a precipitated iron catalyst.

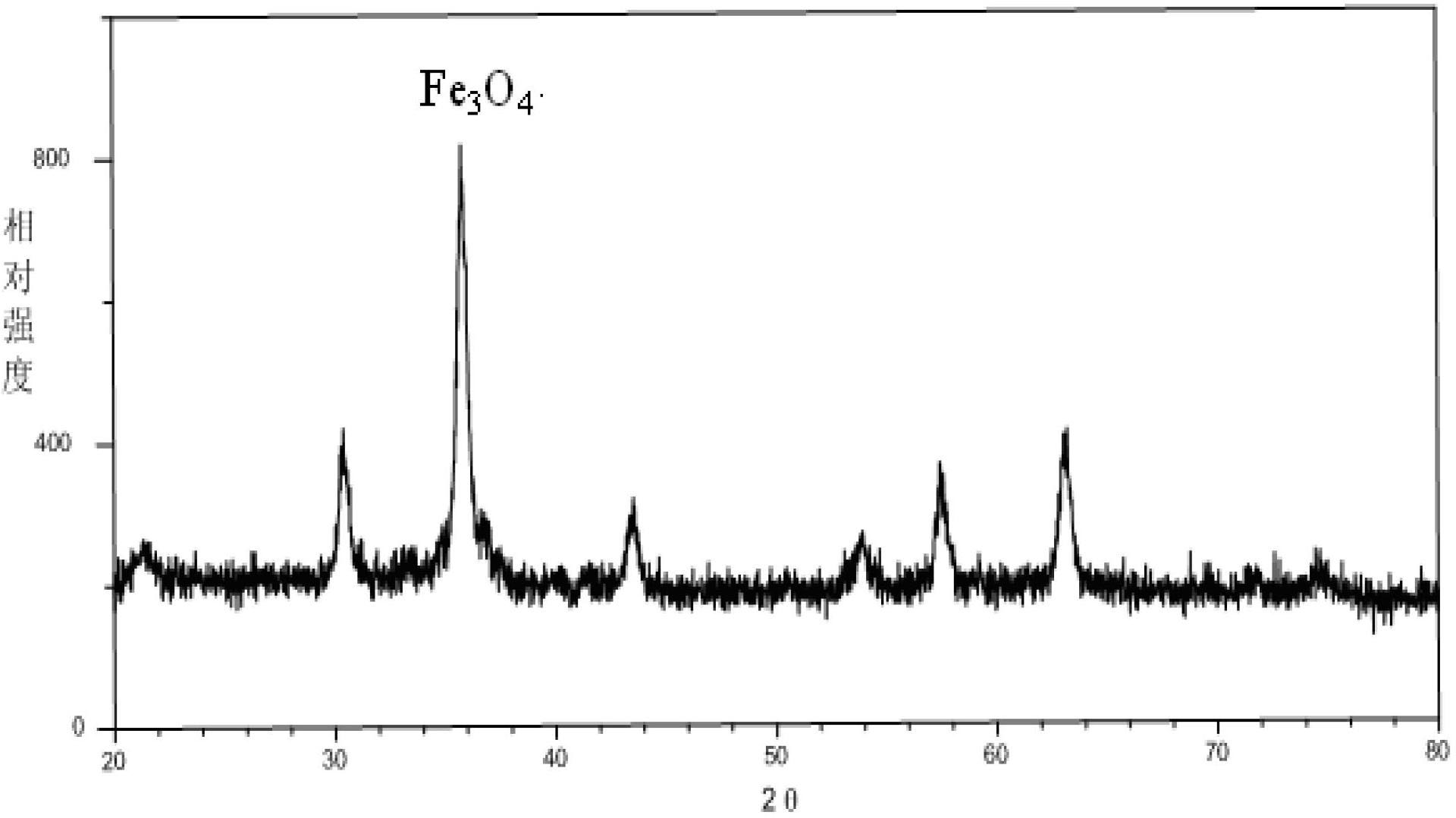

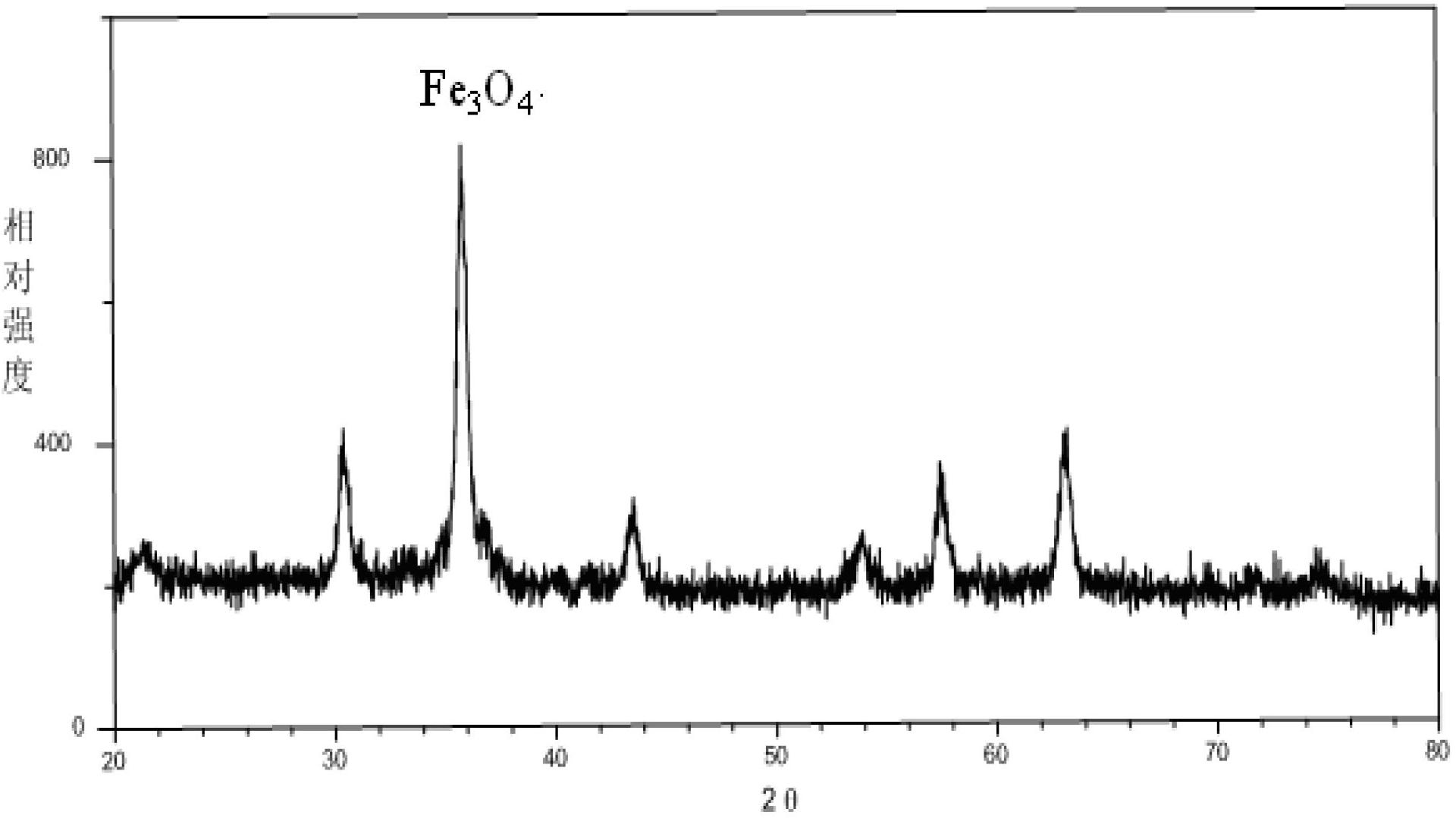

[0028] The present invention from the stable target phase magnetite Fe 3 o 4 Starting with the addition of magnesium-aluminum sol, silica sol and potassium-containi...

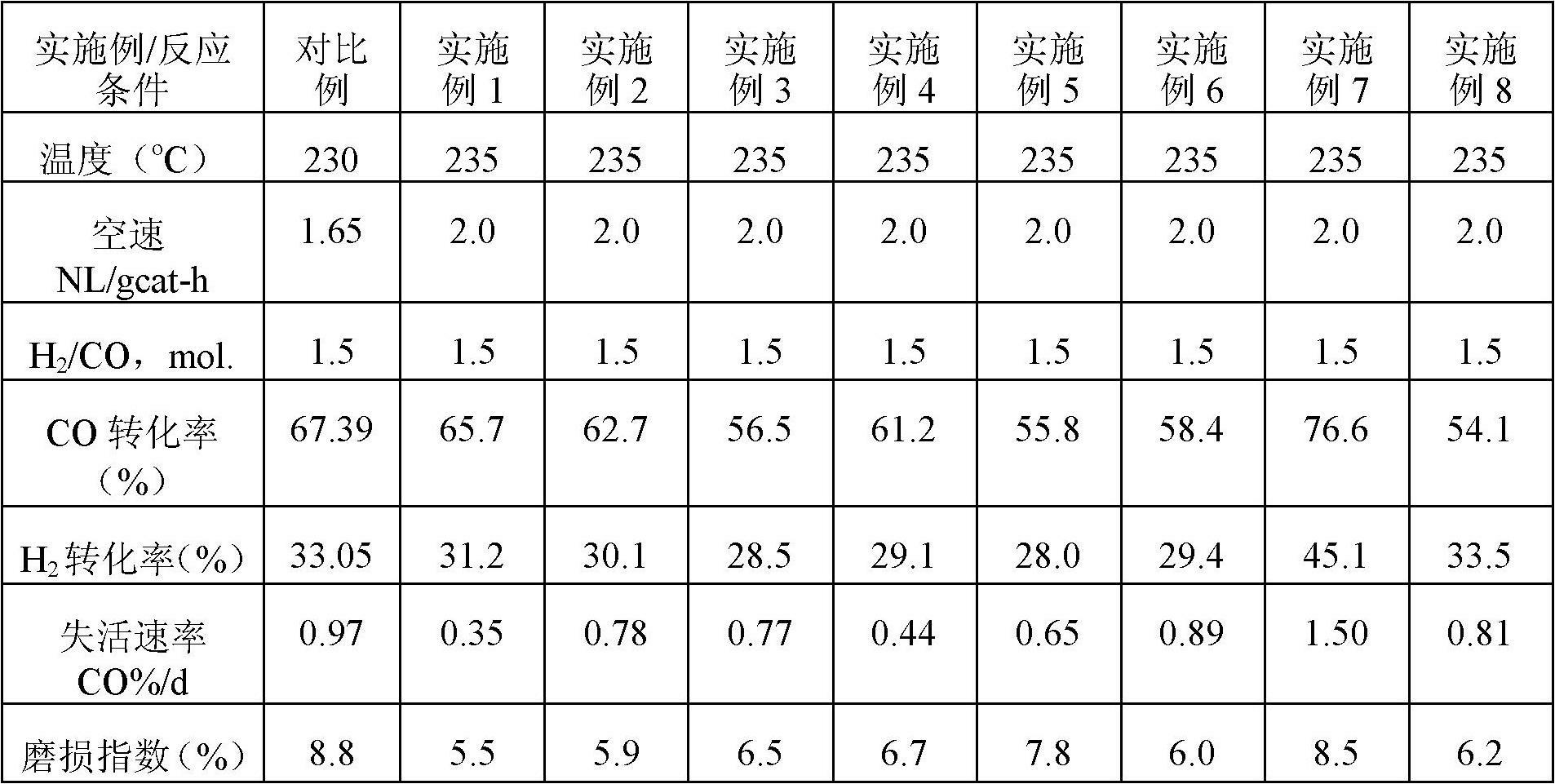

Embodiment 1

[0045] 3000g of Fe(NO 3 ) 3 ·7H 2 O, 1200g of FeSO 4 ·7H 2 O and 150 g Cu(NO 3 ) 2 ·3H 2 O was respectively dissolved (diluted) in distilled water, prepared into ferric iron and ferrous iron solutions with a concentration of 5% by mass percentage, mixed the above three metal salt solutions, stirred evenly and introduced nitrogen, heated under nitrogen atmosphere to 70°C to obtain a mixed salt solution.

[0046] Heat the ammonium carbonate solution with a concentration of 10% by mass to 60°C, use a pump to simultaneously add the ammonium carbonate solution and the mixed salt solution into a 20L stirred tank, heat the stirred tank with a jacket, maintain the temperature at 70°C, and pump The speed is carried out according to the metering ratio of the acidic solution and the alkaline solution. Under the protection of nitrogen, the precipitation is carried out under the conditions of a stirring rate of 200 rpm and a pH value of 7 to obtain a precipitation slurry. The preci...

Embodiment 2

[0052] 3500g of Fe(NO 3 ) 3 ·7H 2 O, 800g of FeSO 4 ·7H 2 O and 120 g Cu(NO 3 ) 2 ·3H 2 O was respectively dissolved (diluted) in distilled water, prepared into ferric iron and ferrous iron solutions with a concentration of 5% by mass percentage, mixed the above three metal salt solutions, stirred evenly and introduced nitrogen, heated under nitrogen atmosphere to 70°C to obtain a mixed salt solution.

[0053] Heat the ammonium carbonate solution with a concentration of 10% by mass to 70°C, and simultaneously add the ammonium carbonate solution and the mixed salt solution into a 20L stirred tank with a pump, heat the stirred tank with a jacket, maintain the temperature at 70°C, and pump the The speed is carried out according to the metering ratio of the acidic solution and the alkaline solution. Under the protection of nitrogen, the precipitation is carried out under the conditions of a stirring rate of 200 rpm and a pH value of 6 to obtain a precipitation slurry. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com