Titanium dioxide nanotube carried palladium nano catalyst and preparation method of same

A titanium dioxide and palladium nanotechnology, which is applied in the field of titanium dioxide nanotube-supported palladium nanocatalyst and its preparation, can solve the problems of difficult application of catalytic system and industrialization process, small number of particles, etc. efficiency, increasing the output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

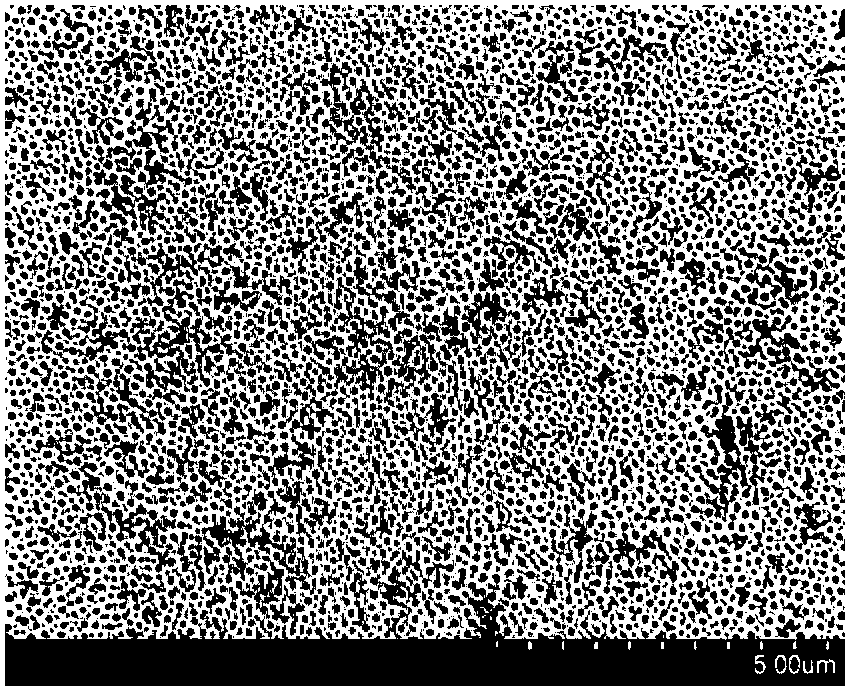

[0032] Preparation of titania nanotube array electrodes:

[0033] 1. A two-electrode electrochemical cell system is adopted, with a titanium sheet (diameter 1.1 cm, purity 99.9%) as the working electrode and auxiliary electrode, and the distance between the two electrodes is controlled to be 2 cm. In the alcohol electrolyte, the anodic oxidation potential is controlled at 60V, and the treatment time is 1h. Take it out and rinse it to dry naturally;

[0034] 2. Transfer the anodized sample to a muffle furnace for annealing, control the heating rate to 2.5°C / min, and when the temperature rises to 400°C, turn to a constant temperature and stay for 30 minutes. TiO2 nanotube arrays can be obtained;

[0035] 3. Polish the titanium dioxide nanotube array with metallographic sandpaper (2500 mesh), after ultrasonic cleaning, transfer it to an electrolytic cell containing 5% perchloric acid + 95% acetic acid solution, control the anodic oxidation potential to 50V, and process time for ...

Embodiment 2

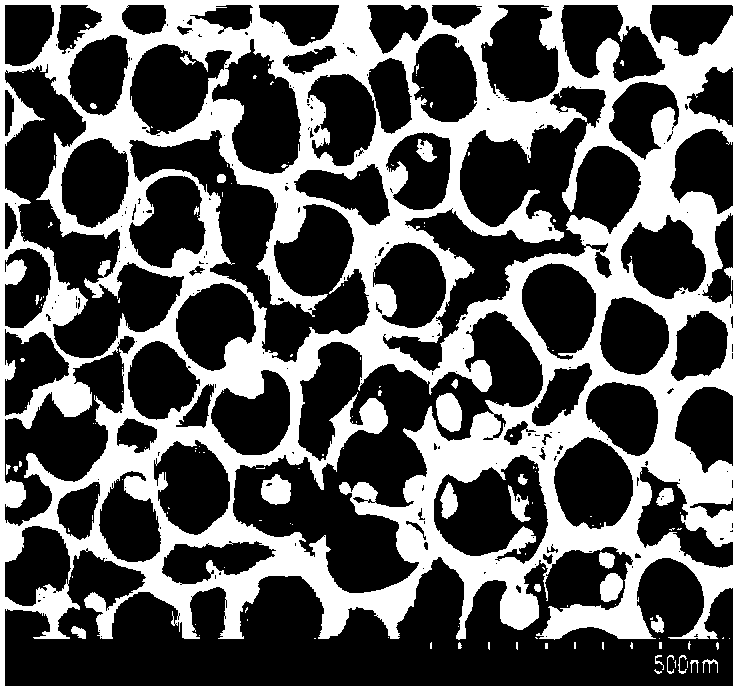

[0037] Electroless deposition of metallic palladium nanoparticles on titania nanotube array electrodes:

[0038] 1. Preparation of palladium nanoparticle chemical deposition solution: Weigh an appropriate amount of PdCL 2 , HCL and ethylene glycol, dissolved in deionized water and passed through sulfuric acid solution to prepare 6.0g / L PdCl 2 The aqueous solution of +14.0ml / L HCl+20.0mL / L ethylene glycol is designated as solution A;

[0039] 2. Weigh an appropriate amount of NaBH 4 , dissolved in deionized water to prepare 20.0g / L NaBH 4 Solution, denoted as solution B;

[0040] 3. First, take 4 beakers and discharge them in turn, and add appropriate amount of solution A, deionized water, solution B and deionized water to them respectively; secondly, put the titanium dioxide nanotube array electrode according to solution A; deionized water; solution B and The deionized water was sequentially soaked for 10 s, and the treatment was repeated 10 times to prepare metal palladiu...

Embodiment 3

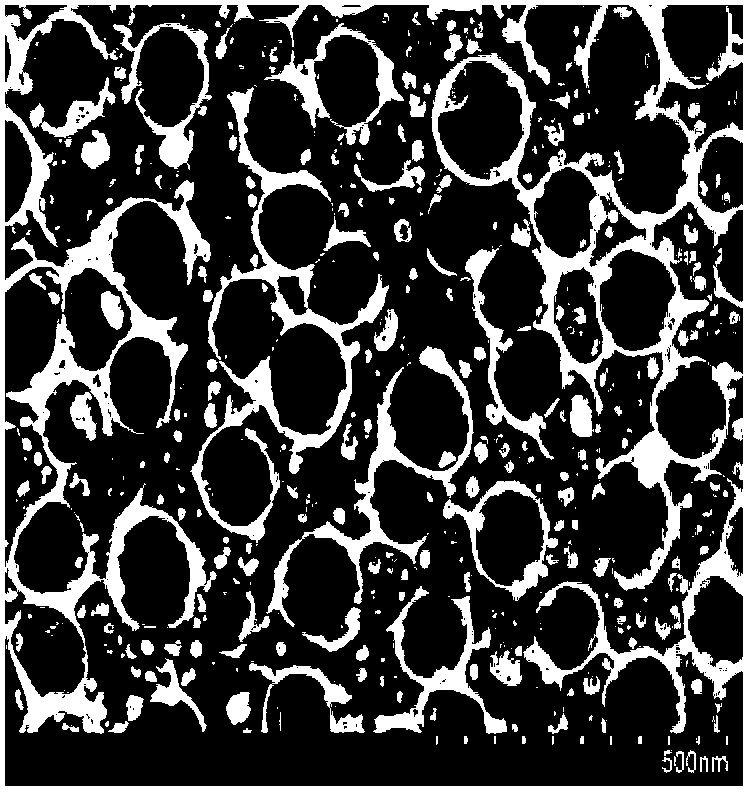

[0042] "Electrochemical post-treatment" process of palladium catalyst nanoparticles:

[0043] 1. Preparation of the "electrochemical post-treatment" solution: Weigh potassium hydroxide, dissolve it in deionized water, and prepare a 2.0M KOH solution, which is recorded as the "electrochemical post-treatment" solution.

[0044] 2. Adopt a three-electrode electrochemical electrolytic cell system, add an appropriate amount of "electrochemical post-treatment" solution to the electrolytic cell, use a titanium dioxide nanotube array-loaded palladium electrode as the working electrode, and a Pd sheet and a saturated calomel electrode (SCE) as the working electrode, respectively. Auxiliary and reference electrodes. Electrochemical program potential step technology is used for processing, the upper limit potential (Eu) is 4.55V, the upper limit time (tu) is 180s; the lower limit potential (Ed) is -1.95V, the lower limit time (td) is 180s; the processing time is 0.3h. Take it out, wash ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com