Seawater desalinizing technology deeply treated by reverse osmosis membrane after mixing wastewater with seawater

A reverse osmosis membrane, advanced treatment technology, applied in seawater treatment, osmosis/dialysis water/sewage treatment, general water supply saving, etc., can solve the problems of low investment cost, low operation cost, small land occupation, etc. The effect of reducing energy consumption and reducing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

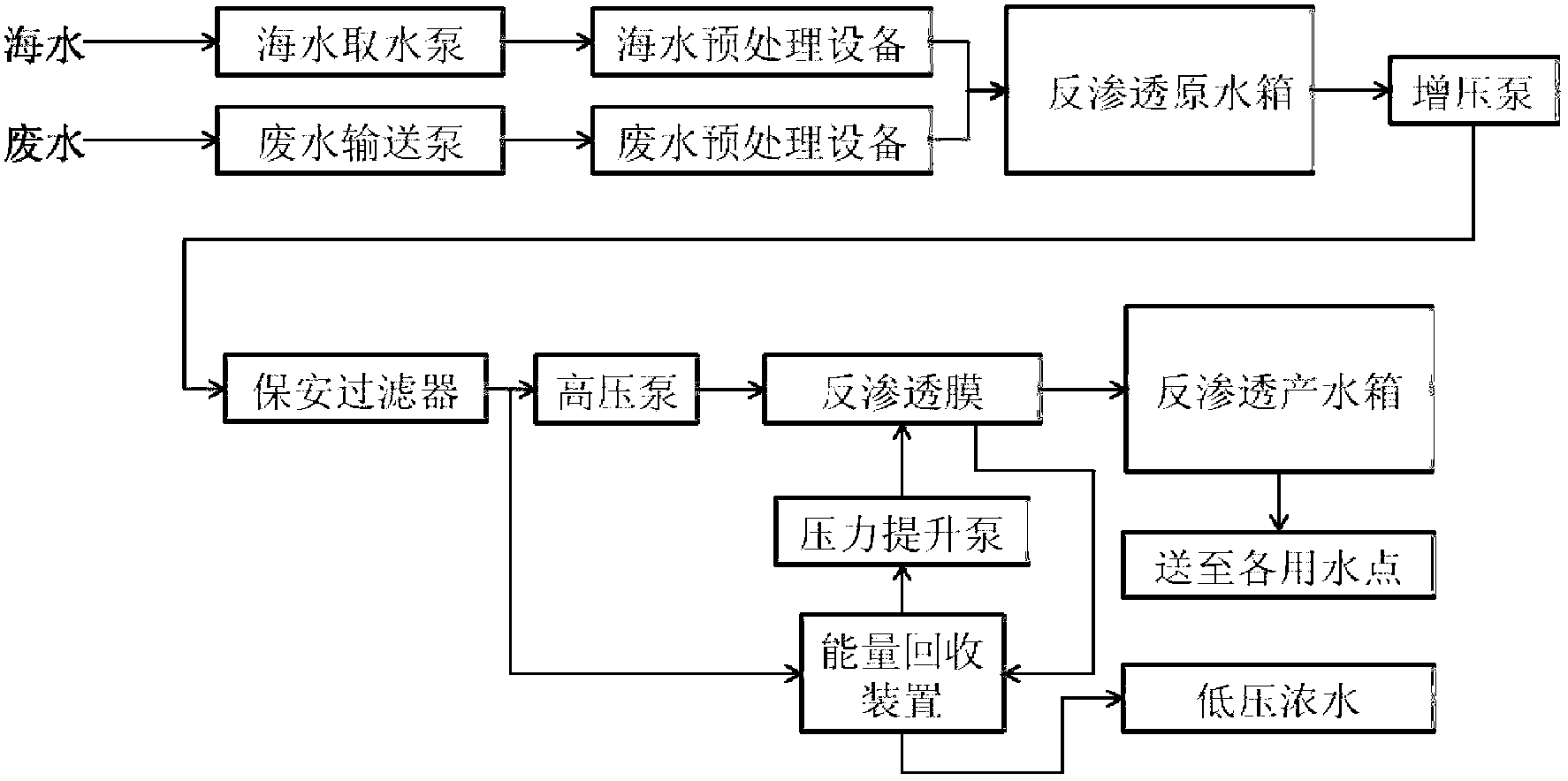

[0021] The mixing ratio of wastewater and seawater is 1:1, 1:2 or 1:3. Such as figure 1 As shown, seawater and wastewater pretreatment are separated: seawater passes through seawater intake pumps and seawater pretreatment equipment (including seawater primary and secondary pretreatment devices) in sequence, and wastewater passes through wastewater transfer pumps and wastewater pretreatment equipment in sequence, and will undergo pretreatment. After the seawater is mixed with the pre-treated up-to-standard wastewater, it enters the reverse osmosis raw water tank, passes through the booster pump and the security filter, and then splits, and part of it enters the reverse osmosis desalination unit (reverse osmosis membrane) through the high-pressure pump, and the reverse osmosis membrane module It is composed of several membrane elements connected in series. The other part goes through an energy recovery device that recovers the energy of high-pressure concentrated water, enters the...

Embodiment 2

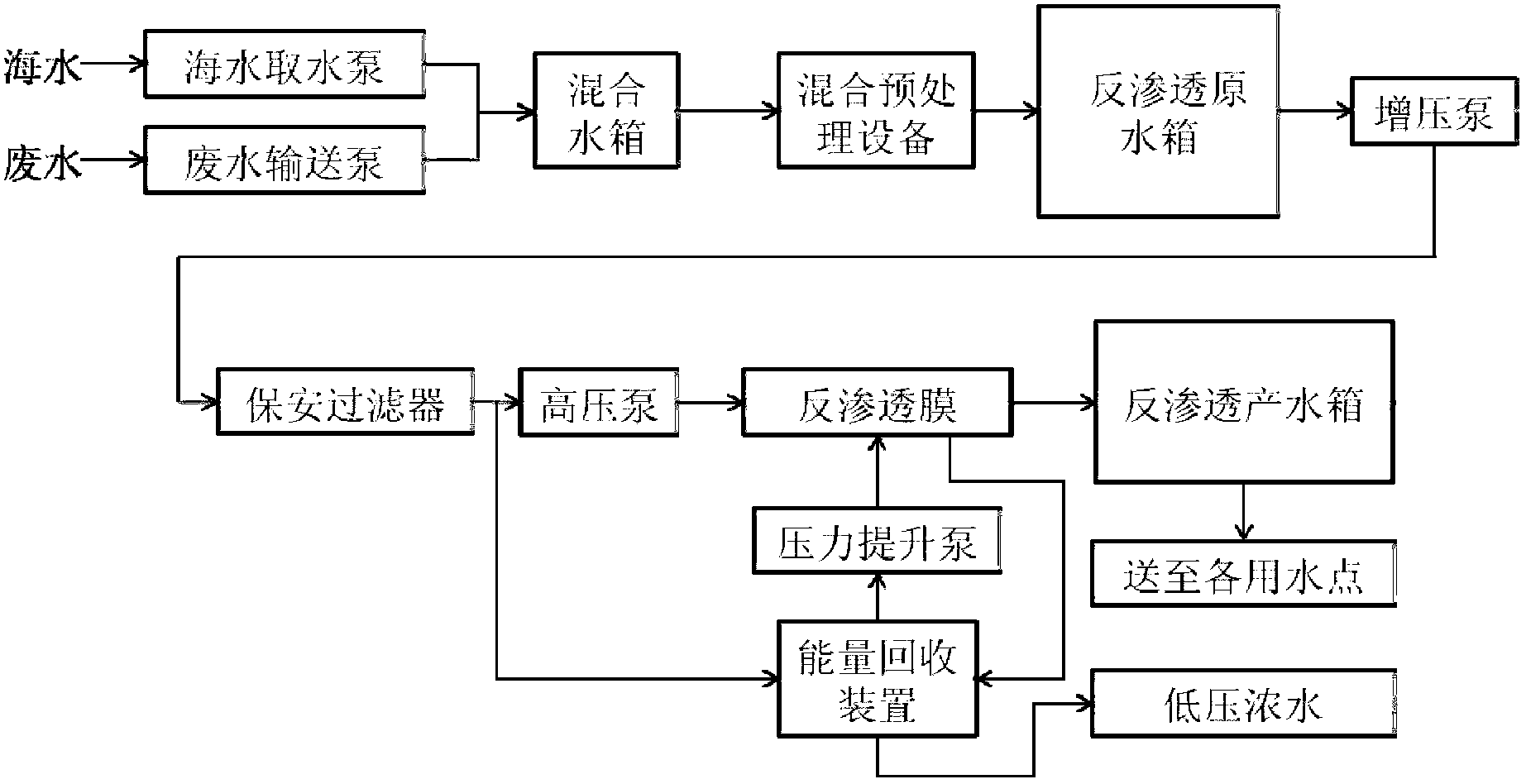

[0023] The mixing ratio of wastewater and seawater is 1:1, 1:2 or 1:3. Such as figure 2 As shown, seawater and wastewater are mixed first and then pretreated: seawater passes through the seawater intake pump, and the wastewater passes through the wastewater transfer pump. The seawater and wastewater enter the mixing tank for mixing, and then enter the mixing pretreatment equipment. The pretreated seawater and wastewater are mixed water. Into the reverse osmosis raw water tank, after passing through the booster pump and security filter, one part enters the reverse osmosis seawater desalination unit (reverse osmosis membrane) through the high pressure pump. The reverse osmosis membrane module is composed of several membrane elements in series, and the other part is recycled The energy recovery device for high-pressure concentrated water energy enters the reverse osmosis membrane through the pressure lift pump, and is filtered by the reverse osmosis membrane. After the product wa...

Embodiment 3

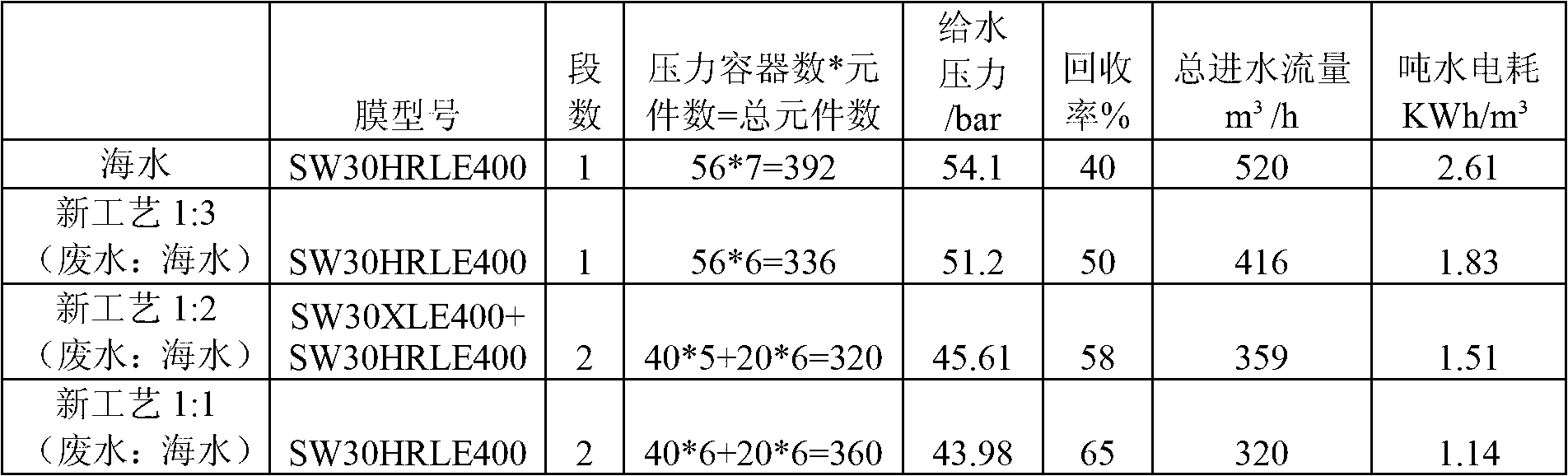

[0024] Example 3. Calculation and analysis

[0025] according to figure 1 or figure 2 The process shown has been simulated by software to simulate a 10,000-ton level seawater desalination project. The entire system is divided into two sets, each with a daily output of 5,000 tons of fresh water, that is, a water output of 208m 3 / h, the operating temperature is 15°C, and the device runs stably. Among them, reverse osmosis desalination (SWRO) feedwater pretreatment technology includes traditional water treatment processes such as disinfection, coagulation / flocculation, clarification, and multi-media filtration, and new water treatment processes such as membrane methods. Membrane pretreatment technologies mainly include microfiltration ( MF), ultrafiltration (UF) and nanofiltration (NF), etc. The main power consumption of the new and old seawater desalination process is calculated and analyzed.

[0026] 1. Simulation analysis with Dow reverse osmosis calculation software ROSA8.0

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com