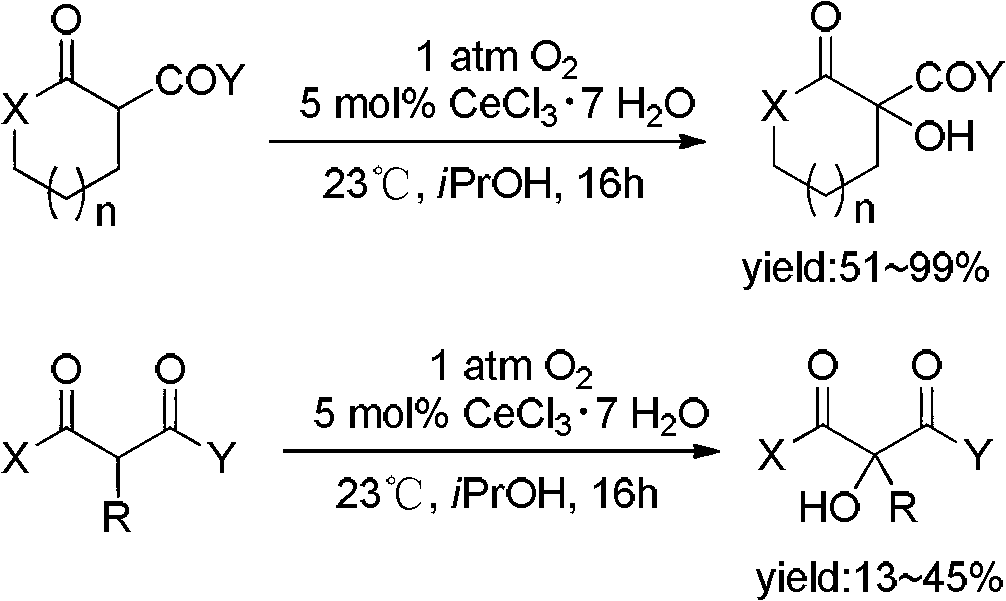

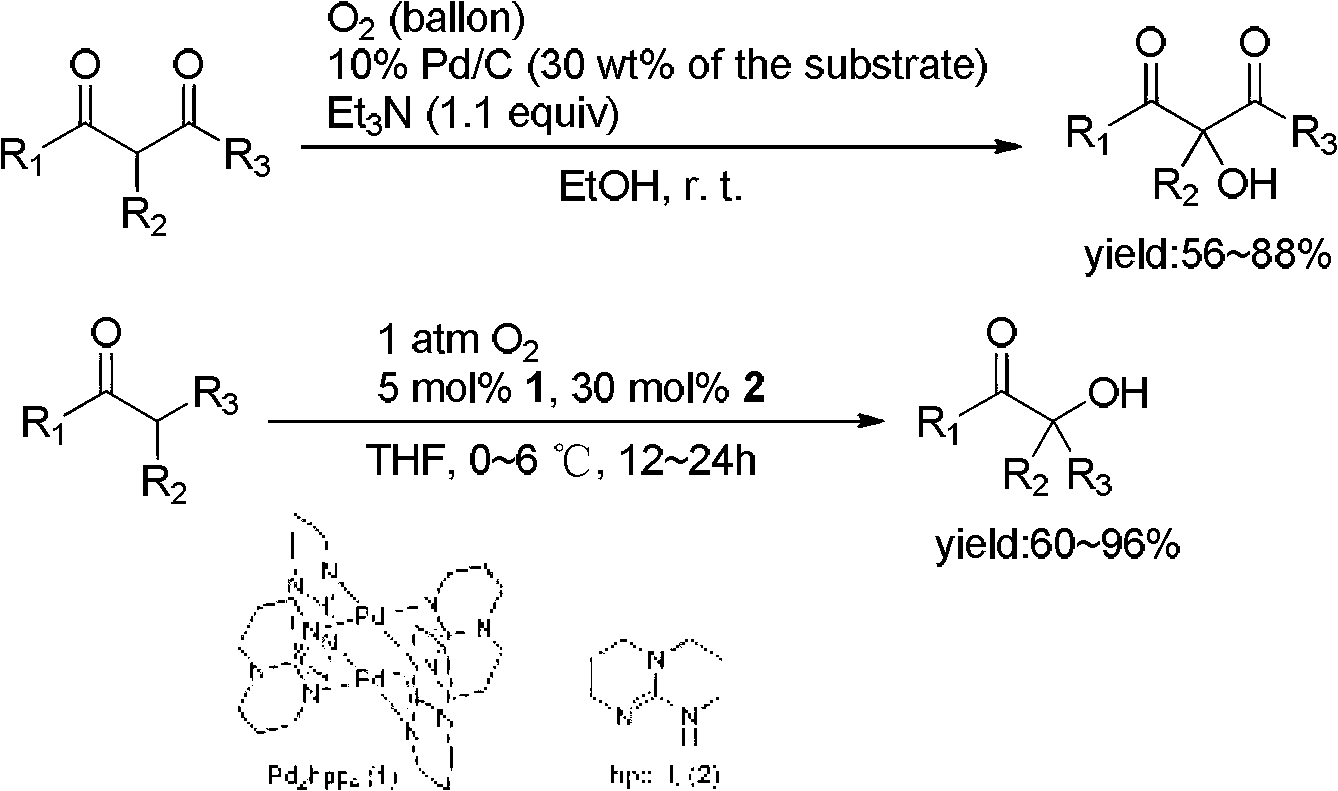

Method for direct alpha-hydroxylation by beta-dicarbonyl compound under action of iodine catalysis

A dicarbonyl compound and hydroxylation technology is applied in the field of direct α-position hydroxylation of β-dicarbonyl compounds catalyzed by iodine, which can solve the problems of harsh reaction conditions, complicated operations, expensive catalysts, etc., and achieves simple product separation and extended application range. , to achieve the effect of simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

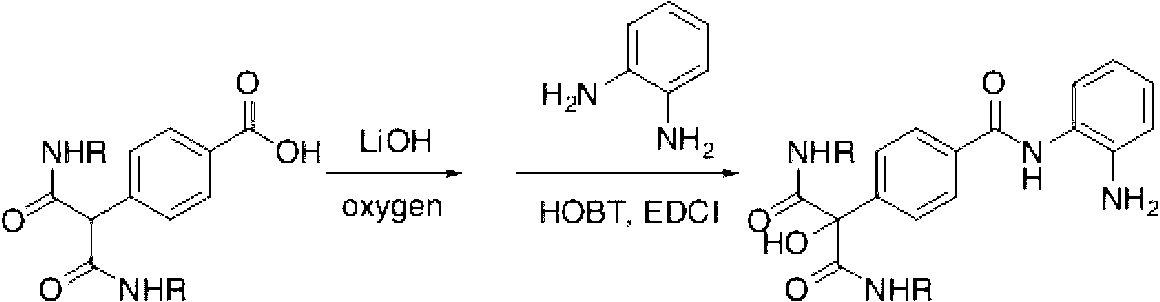

Embodiment 1

[0038] Weigh 7 (1mmol), I in "Reaction Formula 3" 2 (25.6mg, 0.01mmol) and NaOAc (4.1mg, 0.01mmol) in a 25mL round-bottomed flask, then add 10mL THF at 25°C and place it in the air and stir. The reaction was tracked by TLC. After the raw materials disappeared, most of the solvent was removed from the reactant on a rotary evaporator, and 40 mL of water and saturated Na were added. 2 S 2 O 3 Solution until the color of iodine disappears. Extracted with dichloromethane (15mL×3), the organic layer was subjected to anhydrous MgSO 4 After drying, the mixture obtained by rotary evaporation is separated by silica gel column chromatography (the eluent is petroleum ether / ethyl acetate: v / v=6 / 1). The main component obtained is product 8, and the yield is 90%.

Embodiment 2

[0040] Weigh 7 (1mmol), I in "Reaction Formula 3" 2 (128mg, 0.5mmol) and NaOAc (41mg, 0.5mmol) in a 25mL round-bottomed flask, and then add 10mL THF at 25°C and place it in the air and stir. The reaction was tracked by TLC. After the raw materials disappeared, most of the solvent was removed from the reactant on a rotary evaporator, and 40 mL of water and saturated Na were added. 2 S 2 O 3 Solution until the color of iodine disappears. Extracted with dichloromethane (15mL×3), the organic layer was subjected to anhydrous MgSO 4 After drying, the mixture obtained by rotary evaporation is separated by silica gel column chromatography (the eluent is petroleum ether / ethyl acetate: v / v=6 / 1). The main component obtained is product 8, and the yield is 95%.

Embodiment 3

[0042] Weigh 7 (1mmol), I in "Reaction Formula 3" 2 (25.6mg, 0.1mmol) and NaOAc (17mg, 0.1mmol) in a 25mL round-bottomed flask, and then add 10mL THF at 25°C and place it in the air and stir. The reaction was tracked by TLC. After the raw materials disappeared, most of the solvent was removed from the reactants on a rotary evaporator, and 40 mL of water and saturated Na2S were added. 2 O 3 Solution until the color of iodine disappears. Extracted with dichloromethane (15mL×3), the organic layer was subjected to anhydrous MgSO 4 After drying, the mixture obtained by rotary evaporation is separated by silica gel column chromatography (the eluent is petroleum ether / ethyl acetate: v / v=6 / 1). The main component obtained is product 8, and the yield is 93%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com