Organic hybridized telluride having photocatalytic performance and preparation thereof

A technology of diethylenetriamine and crystals, which is applied in the field of organic hybrid tellurides with photocatalytic properties and its preparation, can solve the problems of incomplete degradation of organic dyes and limited photocatalytic applications, and achieve good repeatability and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

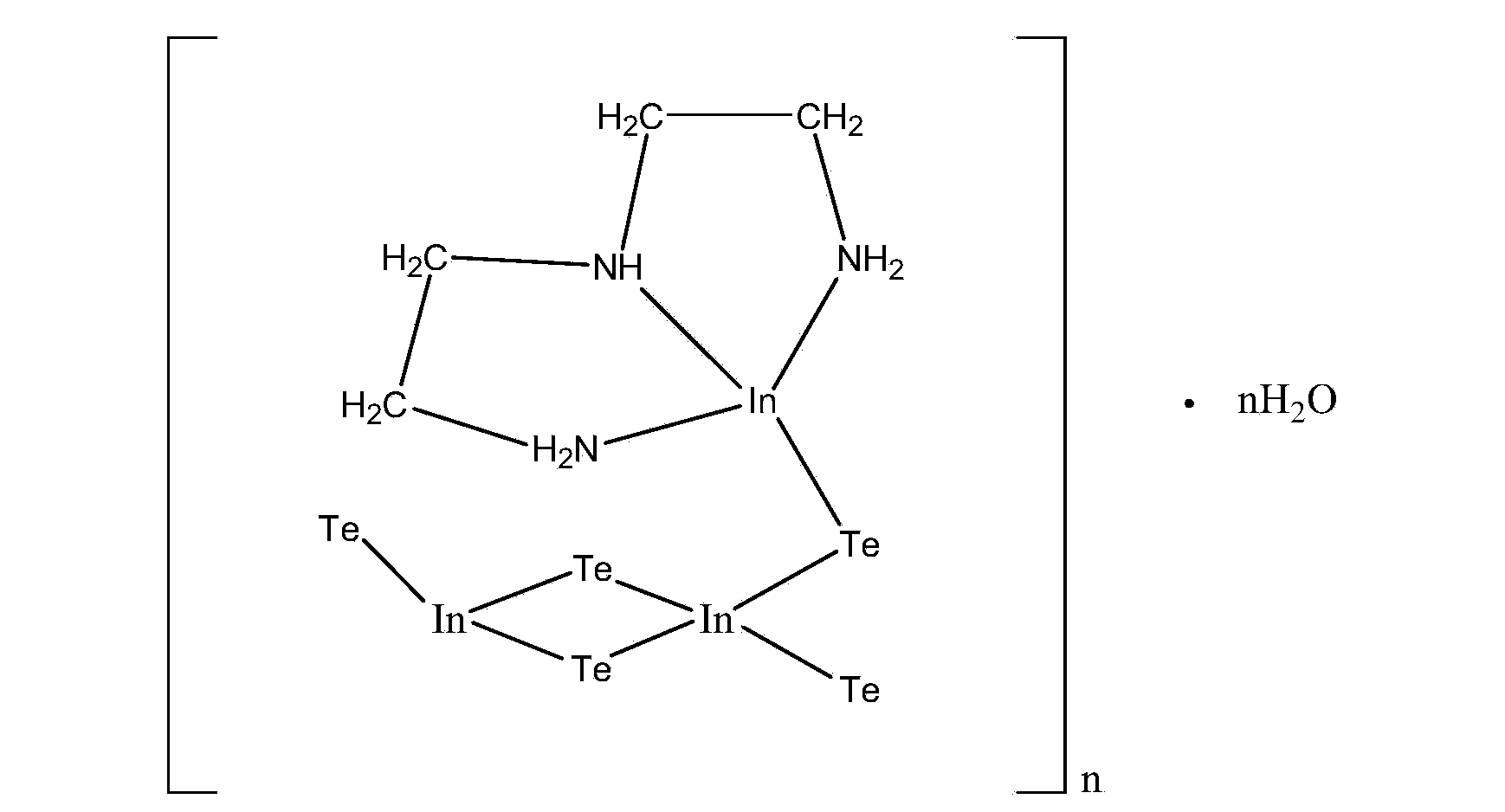

[0022] 1. Compound Preparation

[0023] InCl 3 0.0179g (0.07936mmol), Te0.0057g (0.04467mmol), MgCl 2 ·6H 2 O0.0206g (0.1015mmol) and 3ml of diethylenetriamine were added to a hard glass tube, and the two ends of the glass tube were sealed. Keep at 170°C for 7 days, then cool down to room temperature naturally. Blocky crystals appeared. The crystal sample was taken out, washed with ethanol three times, and dried in a desiccator to obtain 0.0390 g of diethylenetriamine monohydrate indium telluride crystal. Yield 40% (based on tellurium).

Embodiment 2

[0025] InCl 3 0.0179g (0.07936mmol), Te0.0057g (0.04467mmol), MgCl 2 ·6H 2 O0.0206g (0.1015mmol) and 3ml of diethylenetriamine were added to a hard glass tube, and the two ends of the glass tube were sealed. Keep at 160°C for 7 days, then cool down to room temperature naturally. Blocky crystals appeared. The crystal sample was taken out, washed with ethanol three times, and dried in a desiccator to obtain 0.0390 g of diethylenetriamine monohydrate indium telluride crystal. Yield 40% (based on tellurium).

Embodiment 3

[0027] InCl 3 0.0179g (0.07936mmol), Te0.0057g (0.04467mmol), MgCl 2 ·6H 2 O0.0206g (0.1015mmol) and 3ml of diethylenetriamine were added to a hard glass tube, and the two ends of the glass tube were sealed. Keep at 180°C for 7 days, then cool down to room temperature naturally. Blocky crystals appeared. The crystal sample was taken out, washed with ethanol three times, and dried in a desiccator to obtain 0.0390 g of diethylenetriamine monohydrate indium telluride crystal. Yield 40% (based on tellurium).

[0028] The prepared diethylenetriamine indium telluride monohydrate crystal was scanned in the ω-θ mode with Mo Kα (λ=0.071073nm) rays monochromated by a graphite monochromator on a Bruke smart APEXII CCD diffractometer. At 296K, a total of 1271 diffraction spots were collected. By the full matrix least squares method for F 2 The modified structural analysis was done with the SHELXL-97 software package. The molecular formula of the compound is C 8 h 16 In 6 N 6 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com