Biopolymer MA (maleic anhydride)-AMPS (2-acrylamido-2-methyl propane sulfonic acid) water treatment agent and preparation method of biopolymer AM-AMPS water treatment agent

A MA-AMPS, binary copolymer technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as restricting the development of green polymer scale inhibitors, and achieve broad application prospects in the oil field industry market, saving energy time, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

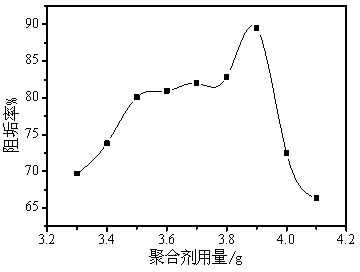

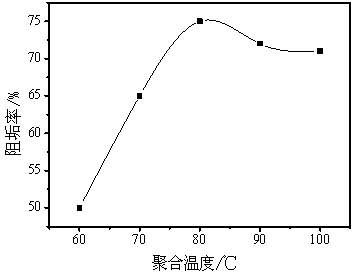

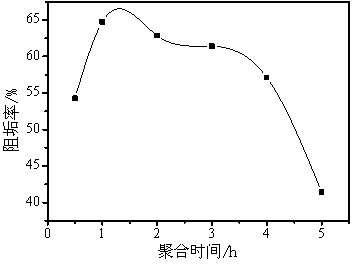

[0026] Embodiment 1: add 9.8g maleic anhydride and 30ml deionized water in the four-necked flask that spherical condenser, dropping funnel and thermometer are housed, after treating that maleic anhydride dissolves completely, add 10.35g 2 -Acrylamide-2-methylpropanesulfonic acid, then raise the temperature to 90°C and react for 3 hours. After the reaction, control the temperature at 40°C~50°C and slowly add about 11ml of 50% NaOH aqueous solution, and raise the temperature to 55°C. Add sodium tungstate according to 3.5% of the mass of maleic anhydride. After reacting for 0.5h, slowly add hydrogen peroxide whose mass ratio is 78% of the total amount of reactants. At the same time, use NaOH to adjust the pH of the solution to 6~6.5, and then Carry out epoxidation reaction at 70°C for 1.5h, then raise the temperature to 90°C, add 3.00g of polymerizing agent potassium persulfate, and polymerize for 1h. After stopping the reaction, the solution becomes a light yellow viscous liquid....

Embodiment 2

[0027] Embodiment 2: add 9.8g maleic anhydride and 30ml deionized water in the four-necked flask that spherical condenser, dropping funnel and thermometer are housed, after treating that maleic anhydride dissolves completely, add 10.35g 2 -Acrylamide-2-methylpropanesulfonic acid, then heat up to 90°C, react for 3 hours, after the reaction, control the temperature at 40°C~50°C and slowly add 11ml of 50% NaOH aqueous solution, heat up to 55°C, Add the transition metal catalyst by 3.5% of the mass of maleic anhydride, after reacting for 0.5h, slowly dropwise add the hydrogen peroxide whose mass ratio is 78% of the total amount of reactants, and adjust the pH of the solution to 6~6.5 with NaOH at the same time, and then Carry out epoxidation reaction at 70°C for 1.5h, then raise the temperature to 90°C, add 3.90g of polymerizing agent potassium persulfate, and polymerize for 1h. After the reaction is stopped, the solution is light yellow viscous liquid.

Embodiment 4

[0029] Add 9.8g of maleic anhydride and 30ml of deionized water into a four-necked flask equipped with a spherical condenser, dropping funnel, and thermometer. After the maleic anhydride is completely dissolved, add 10.35 g of 2-acrylamide -2-Methylpropanesulfonic acid, then heat up to 90°C, react for 3 h, after the reaction, control the temperature at 40°C~50°C, slowly add 11ml of 50% NaOH aqueous solution, raise the temperature to 55°C, Add 3.5% of the mass of the dianhydride to a transition metal catalyst, and after 0.5 h of reaction, slowly add hydrogen peroxide with a mass ratio of 78% of the total amount of reactants, while adjusting the pH of the solution to 6~6.5 with NaOH, and then proceed at 70 °C The epoxidation reaction was carried out for 1.5 h, then the temperature was raised to 90 °C, 4.10 g of the polymerizing agent potassium persulfate was added, and the polymerization reaction was carried out for 1 h. After the reaction was stopped, the solution was light yell...

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com