Graphene/poly Schiff base polymer composite material and preparation method and application thereof

A technology of polySchiff base and composite material, applied in luminescent materials, color-changing fluorescent materials, chemical instruments and methods, etc., can solve the problems of low efficiency, slow discoloration rate, poor conductivity of polySchiff base, etc., and achieve chemical stability. High, increased conductivity, broadening the effect of the spectral range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

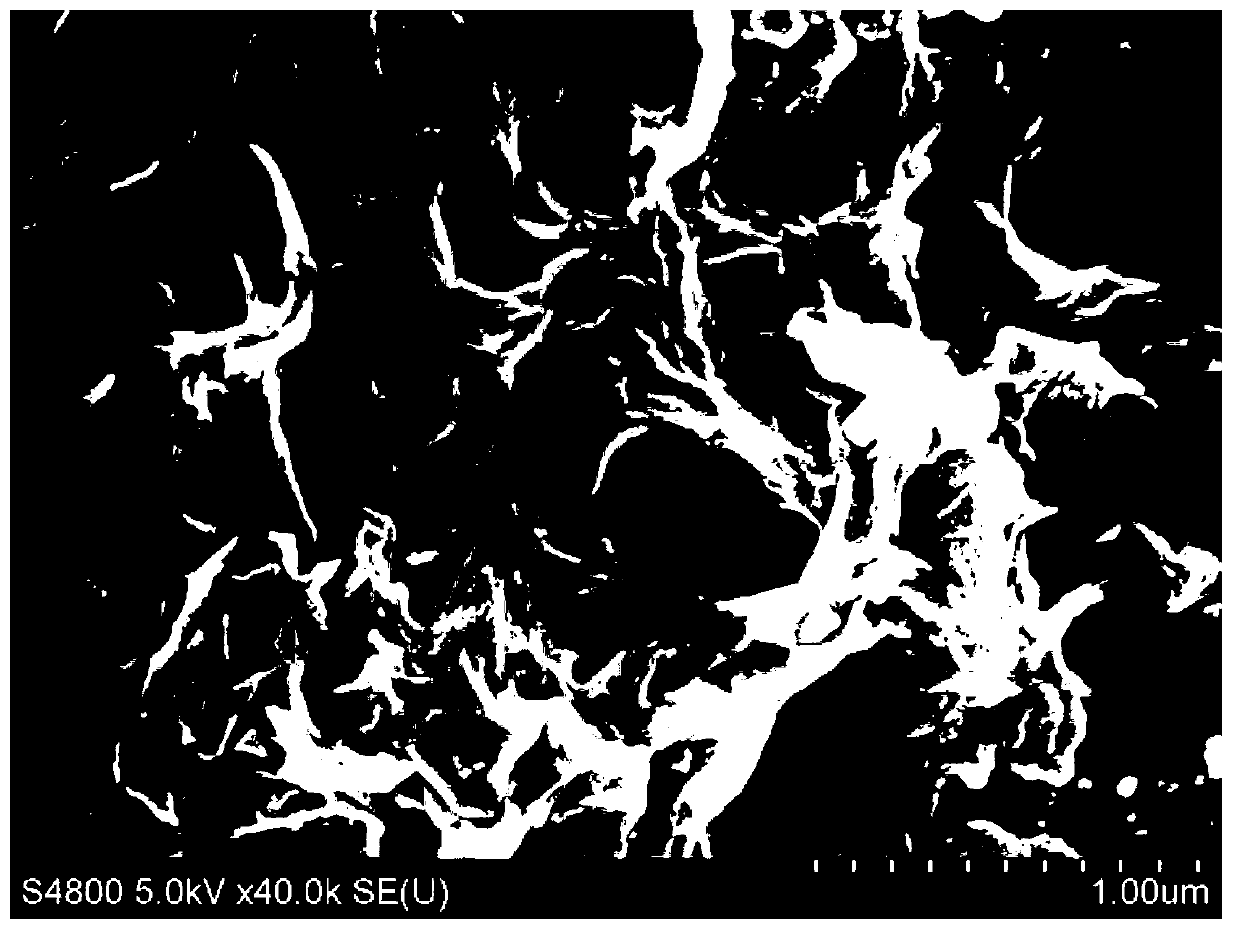

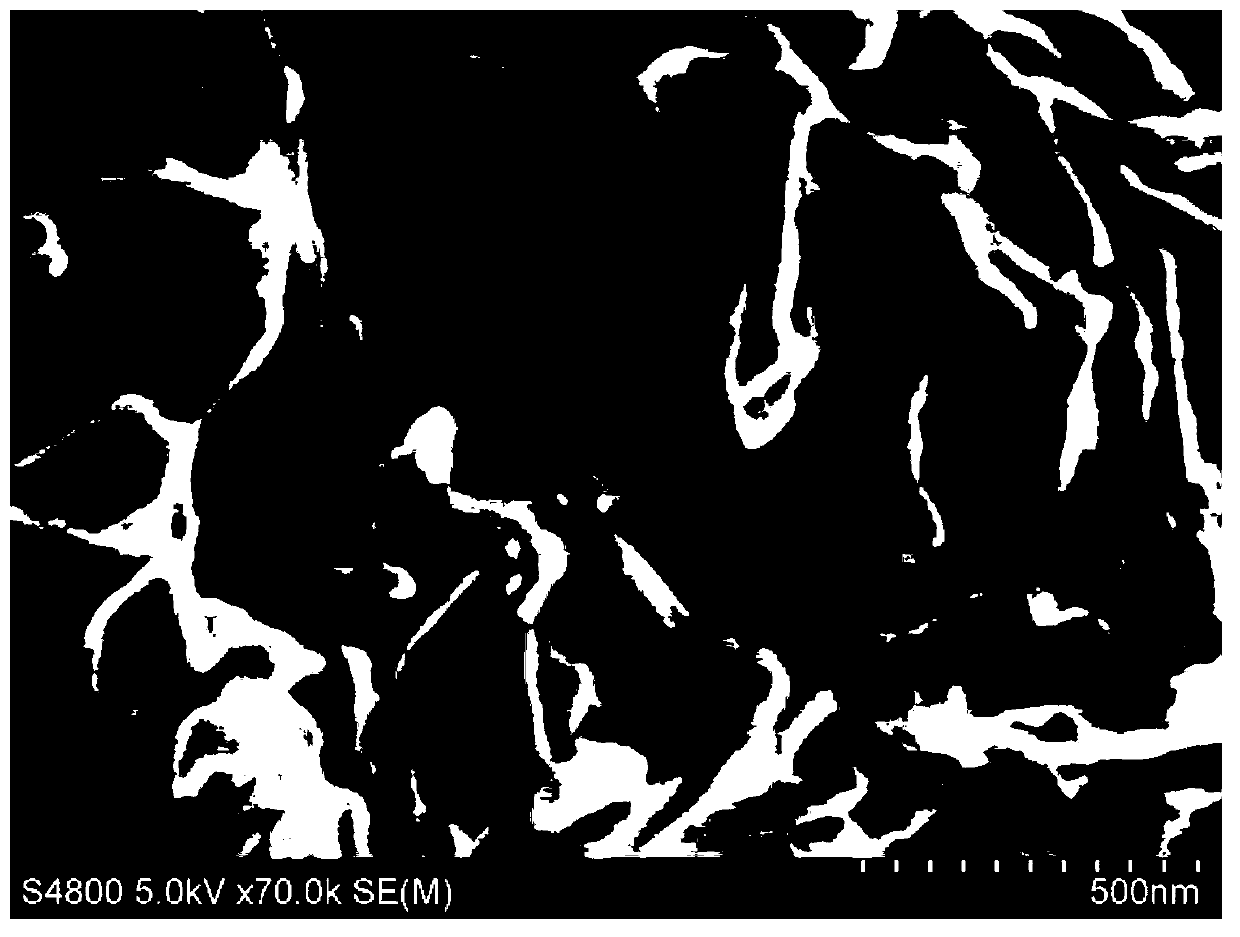

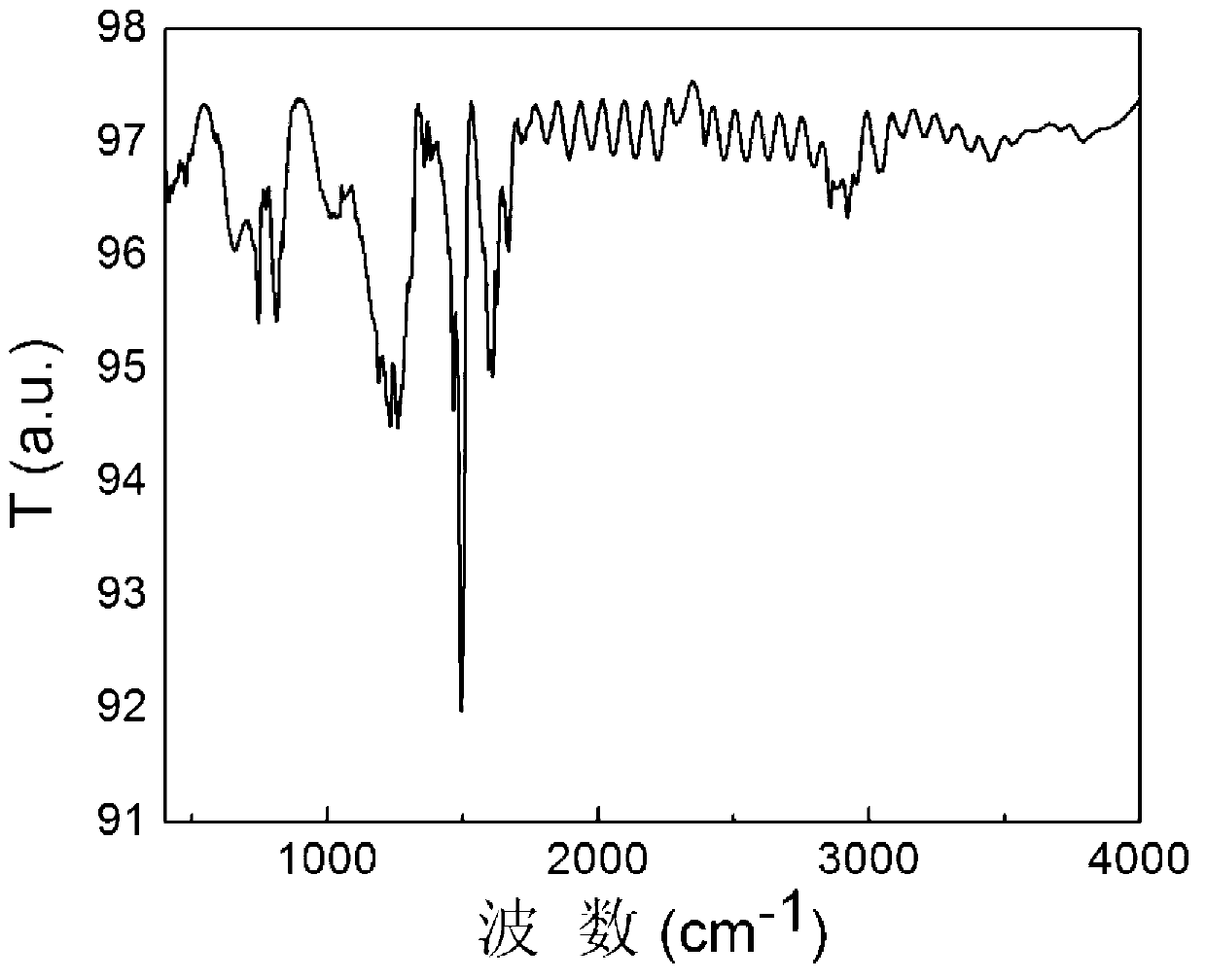

[0038] Specific embodiment one: the structural formula of the graphene / poly-Schiff base polymer composite material of the present embodiment is:

[0039] Among them, n=1~100; R 1 for where R' is H or -CH 3 , m=1~8, R " is (CH 2 ) pCH 3 , p is 0-8.

[0040] The graphene / polySchiff base polymer composite material of the present embodiment grafts graphene and aromatic conjugated polySchiff base, not only has the characteristics of graphene and aromatic conjugated polySchiff base, but also has The effect of synergistic and multifunctional compounding, the obtained composite material can be dissolved in most organic solvents, can be used as a catalyst carrier, has third-order nonlinear characteristics, and has good detection performance; graphene / poly-Schiff base polymer composite In the material, the chemical bonding between graphene and polySchiff base (carbon-carbon coupling) forms intramolecular or intermolecular charge flow, broadens the spectral range, and at the s...

specific Embodiment approach 2

[0041] Embodiment two: the preparation method of the graphene / poly-Schiff base polymer composite material described in embodiment one is carried out in the following steps:

[0042] 1. Using the Hummers method to make graphite into graphite oxide;

[0043] Second, graphite oxide is reduced to graphene with hydrazine hydrate;

[0044] 3. Weigh the polySchiff base, graphene and sarcosine prepared in step 2 and add them to anhydrous N, N'-dimethylformamide, sonicate for 20min to 30min, and then 2 Under protection, heat up to 149-156°C and reflux and stir for 4-10 days. After the reaction is completed, filter, wash the obtained solid phase with methanol, and then put it at a temperature of 60-70°C and use N 2 drying in a protected oven for 10h to 48h to obtain a graphene / poly-Schiff base polymer composite;

[0045] Wherein the mass ratio of graphene and polySchiff base in step 3 is (0.5~1): 1, the mass ratio of sarcosine and polySchiff base is 1: (3~5), the quality of polySchiff...

specific Embodiment approach 3

[0047] Specific embodiment three: the present embodiment is different from the specific implementation two: adopt the Hummers method to make the concrete steps of graphite oxide graphite in the step one:

[0048] A, take by weighing respectively the concentrated sulfuric acid, graphite powder, sodium nitrate, potassium permanganate and distilled water that mass percent concentration is 98%, wherein the ratio of the volume of graphite powder quality to mass percent concentration is 98% concentrated sulfuric acid is 1g : (20 ~ 50) mL, the mass ratio of graphite powder and sodium nitrate is 1: (0.2 ~ 1.5), the mass ratio of graphite powder and potassium permanganate is 1: (4 ~ 7), the mass ratio of graphite powder and distilled water The volume ratio is 1g: (20-30) mL;

[0049] B, the graphite powder and sodium nitrate that step one weighs are mixed homogeneously, obtain mixture; The concentrated sulfuric acid that the mass percentage concentration that step one weighs is 98% is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com