UV (Ultraviolet) offset printing ink and preparation method thereof

An offset printing ink and resin technology, applied in the field of printing ink, can solve the problems of poor resin wetting and dispersing, insufficient ink thixotropy, limited drying speed, etc., and achieves excellent dot reproduction performance, good resin wetting and dispersing, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

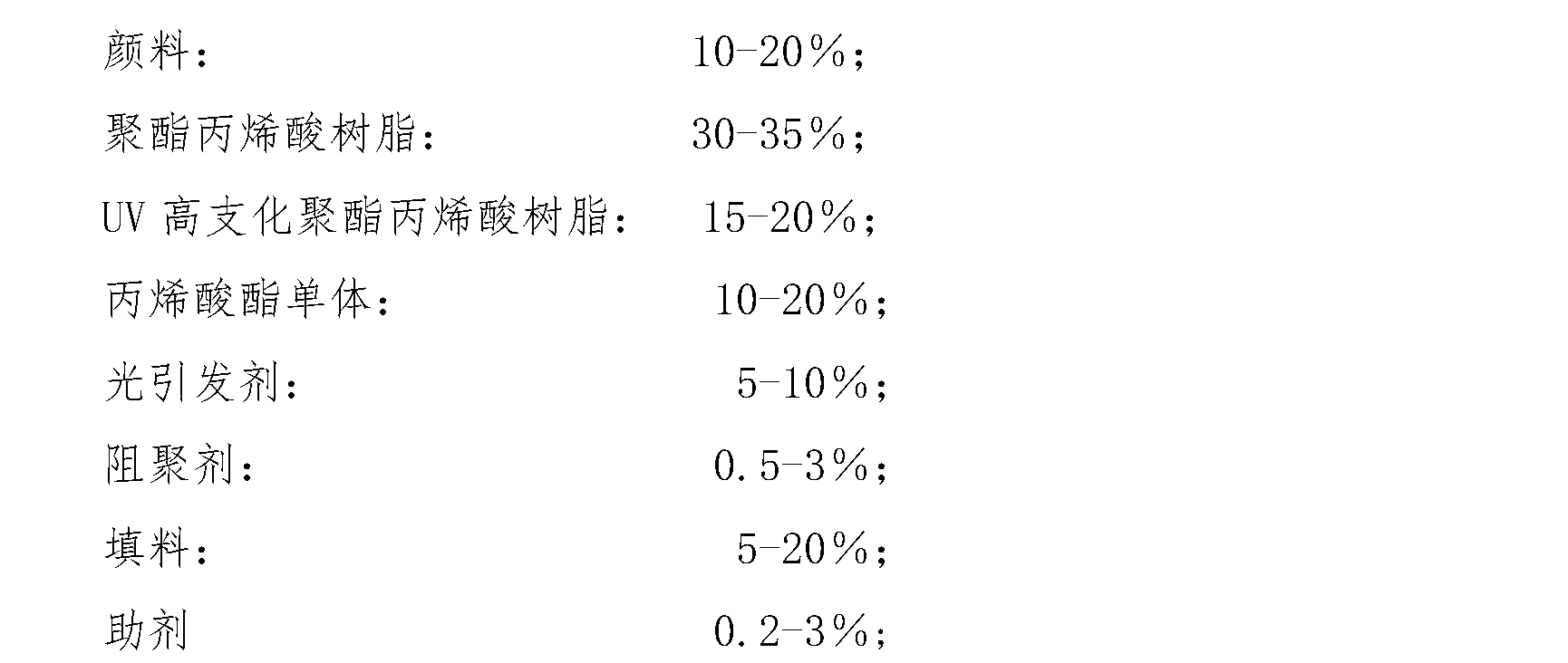

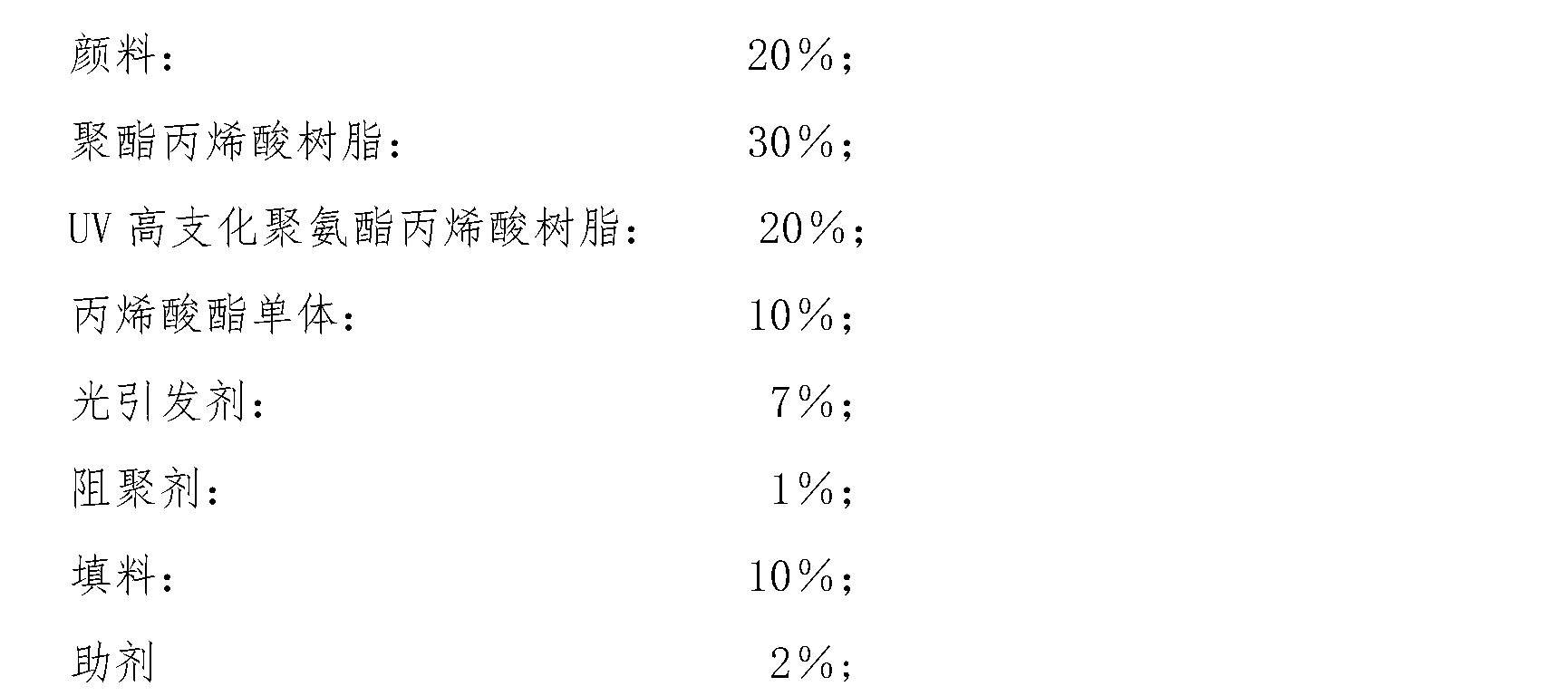

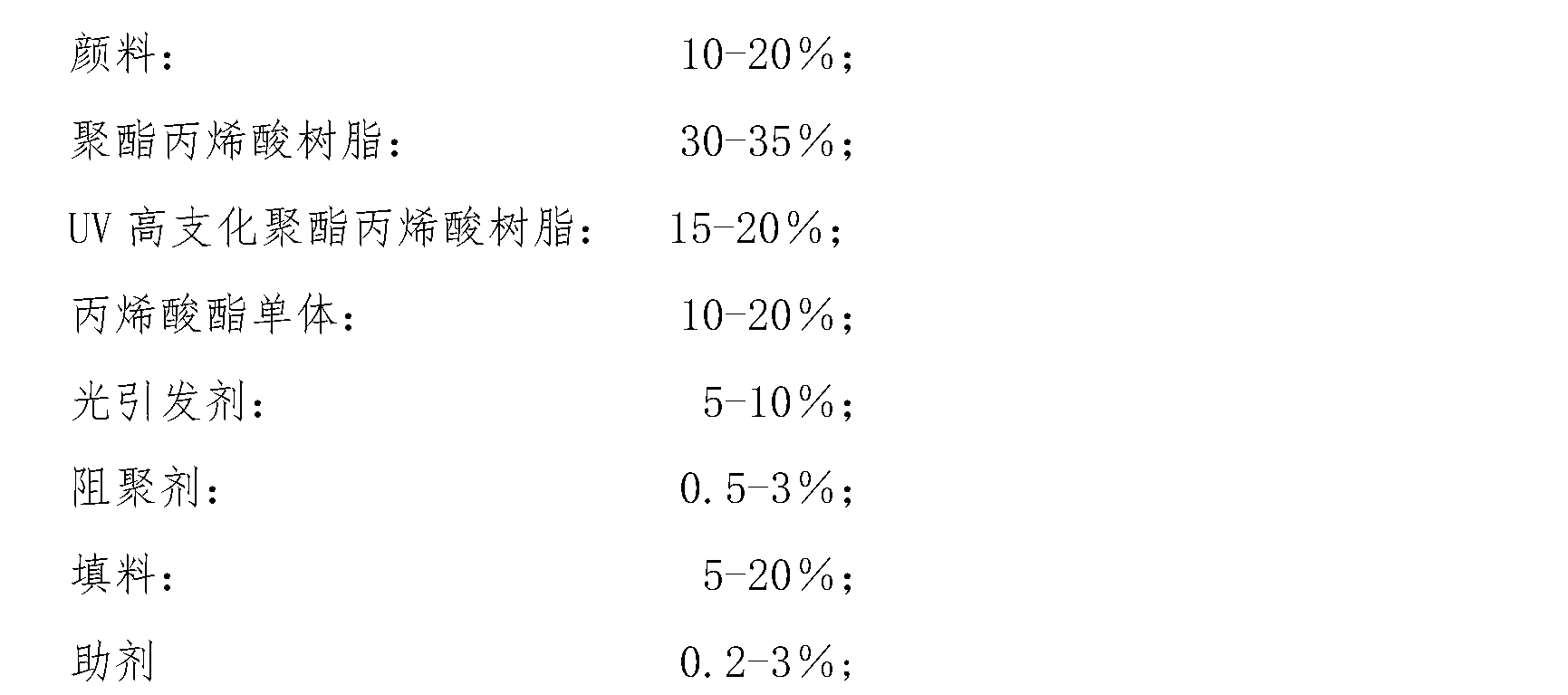

[0029] One, raw material preparation: batching with the weight percentage of each component shown in table 1:

[0030] Table 1

[0031]

Example ①

Example ②

Example ③

Example ④

20

20

benzidine yellow

20

13

UV hyperbranched polyester acrylic resin

15

17

20

20

Pentaerythritol tetraacrylate UV resin

35

33

30

35

Photoinitiator 907

4

4

4

7

Photoinitiator 1173

3

3

3

3

Wetting and dispersing agent 7710

2

2

2

3

1

1

1

1

8

8

8

6

silica

2

2

2

2

10

10

10

10

[0032] Through the ring-opening polymerization of methyltetrahydrophthalic anhydri...

Embodiment 5~8

[0044] One, raw material preparation: batching with the weight percentage of each component shown in table 2:

[0045] Table 2

[0046]

Example 5

Example 6

Example 7

Example 8

20

20

benzidine yellow

20

15

UV hyperbranched polyester acrylic resin

20

17

15

15

epoxy acrylic resin

30

33

35

35

Photoinitiator 907

4

4

4

7

Photoinitiator 1173

3

3

3

3

Wetting and dispersing agent 7710

2

2

2

3

1

1

1

1

8

8

8

6

silica

2

2

2

2

10

10

10

13

[0047] Through the ring-opening polymerization of methyltetrahydrophthalic anhydride and glycidyl alc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com