Fluorescent transparent coating capable of realizing full colors, preparation method and luminous device using fluorescent transparent coating

A technology of transparent coating and light-emitting device, which is applied in the direction of lighting devices, applications, coatings, etc., can solve the problems of cumbersome coating preparation methods, difficult large-area coating, slow curing speed, etc., and achieve a wide range of substrates and environmental protection Good performance and fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

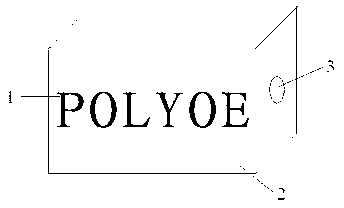

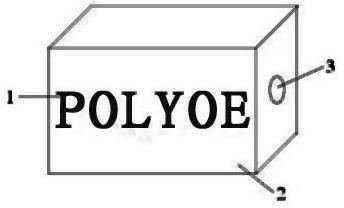

Image

Examples

Embodiment 1

[0030] A full-color fluorescent clear coating consisting of quantum dots and UV-curable clear ink. Quantum dots, also known as semiconductor nanocrystals, include nano-semiconductor materials of Group II-VI or Group III-V of the periodic table of elements and their corresponding core-shell structures; specifically including CdSe, CdTe, CdS, ZnSe, ZnS, GaP, GaN , GaAs, InP, InN, InAs, InSb, PbS, PbSe and other quantum dots; or with the above materials as the core, CdSe, CdS, ZnSe, ZnS, CdO, ZnO, SiO 2 A nano-semiconductor material with a core-shell structure formed as a shell. By controlling the size and composition of quantum dots, the emission wavelength of quantum dots can be adjusted to obtain a variety of distinguishable colors. Generally, the particle diameter of quantum dots is between 1 and 10 nm. Taking (CdSe)ZnS core-shell quantum dots as an example, when the CdSe core diameter is 1.8nm, it emits blue light; when the CdSe core diameter is 7nm, it emits red light. T...

Embodiment 2

[0032]Commercial UV curable ink products without added pigments include epoxy acrylate UV curable inks, polyurethane acrylate UV curable inks, polyester acrylate UV curable inks, polyether acrylate UV curable inks, polyacrylic acid One or more of propyl ester and unsaturated polyester UV curing inks. Mix the UV-curable transparent ink resin with a mass percentage of 75% and (CdSe)ZnS core-shell quantum dots with a mass percentage of 25% and a core diameter of 7nm, add it to the material tank and stir for 120min through a disperser; add 0.2 mm zirconia beads, grind for 8 hours, the UV curable transparent ink with quantum dots has a viscosity of 100mPaS at 30°C; print the target image on the glass with the ground UV curable transparent ink with quantum dots by an inkjet printer; While printing the target image or after printing, it is irradiated with ultraviolet light to cure it. The radiation amount of ultraviolet light is 10W / cm, and the irradiation time is 300 seconds. The fo...

Embodiment 3

[0034] Mix the UV curable transparent ink with a mass percentage of 88% and CdSe quantum dots with a mass percentage of 12% and a particle size of 3.2nm, add it to the bucket and stir it for 75min through a disperser; add 0.2mm zirconia beads, Grinding for 5 hours, the viscosity of the ground UV curable transparent ink containing quantum dots is 50mPaS at 30°C; the ground UV curable transparent ink containing quantum dots is used to print the target image on the transparent resin by an inkjet printer; the printed target image At the same time or after printing, irradiate with ultraviolet light to cure it. The radiation amount of ultraviolet light is 1000W / cm, and the irradiation time is 100 seconds. The formed fluorescent transparent coating can emit green light after being excited by blue light or ultraviolet LED light source. Then the transparent resin is cut into the required size and shape, and assembled with a light source that excites fluorescence to form a light-emitting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com