Visible light degradation agent for dyeing wastewater treatment and preparation method of visible light degradation agent

A printing and dyeing wastewater and visible light technology, which is applied in energy wastewater treatment, textile industry wastewater treatment, light water/sewage treatment, etc., can solve the problems of low quantum efficiency and low effective utilization of solar energy, and achieve reduced bandgap width, excellent The effect of catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

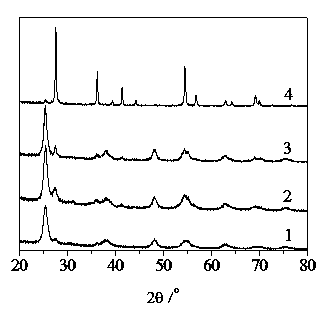

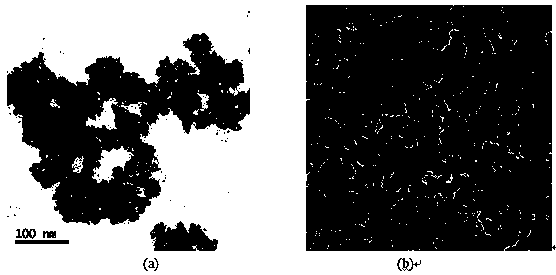

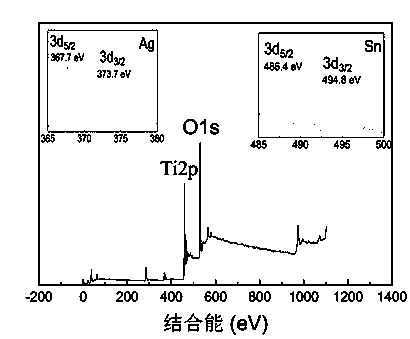

Image

Examples

Embodiment 1

[0030] (1) Weigh 0.054g SnCl 2 2H 2 O (the molar ratio of Sn and Ti is 1:100), 8 mL of butyl titanate and 56 mL of isoamyl acetate are poured into the same three-necked flask, and the magnetic stirring is turned on to mix them evenly to form a solution;

[0031] (2) After about 5 minutes, turn on the air pump switch, with 50 L·min -1 The air is sent to the three-necked flask with a small amount of water at a certain rate, and a small amount of water vapor is brought into the three-necked flask with butyl titanate solution through another interface. The mass of water in the gas is 2.5-3.5g· L -1 , continue magnetic stirring, after 15 minutes, the mixed solution turns from colorless and transparent to turbid, and finally turns into a white emulsion, and the reaction stops after 2 hours;

[0032] (3) Distill the three-neck flask containing the white emulsion under reduced pressure to collect isoamyl acetate for reuse in the next preparation; collect the white powder, put it i...

Embodiment 2

[0037] In step (1), weigh 0.027g of SnCl 2 2H 2 O (the molar ratio of Sn and Ti is 0.5:100), 6.5 mL of ethyl titanate and 60 mL of ethyl acetate were poured into the same three-necked flask, and magnetic stirring was turned on to mix them evenly to form a solution. According to the technical scheme of Example 1, calcined at a temperature of 400 ° C to obtain nano-TiO doped with Sn0.5% and Ag0.1% by double metals 2 visible light catalyst. Labeled as Sn0.5-Ag0.1-400.

Embodiment 3

[0039] According to the technical scheme of Example 1, the molar ratio of Ag to Ti is 0.5:100 in step (5), that is, weigh 0.020 g of silver nitrate and dissolve it in 8 mL of absolute ethanol, and mix with the nanoparticles obtained in step (4) in Grind in an agate mortar until dry. Obtain bimetallic doped Sn1%, Ag0.5% nano-TiO calcined at 400 °C 2 visible light catalyst. Labeled as Sn1-Ag0.5-400.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com