Itaconic acid-based epoxy resin composition and method for preparing cured substance

An itaconic acid-based epoxy resin and epoxy resin curing technology, which is applied in the field of itaconic acid-based epoxy resin composition and preparation of itaconic acid-based epoxy resin cured products, to achieve strong operability and flexible performance adjustment , easy-to-implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

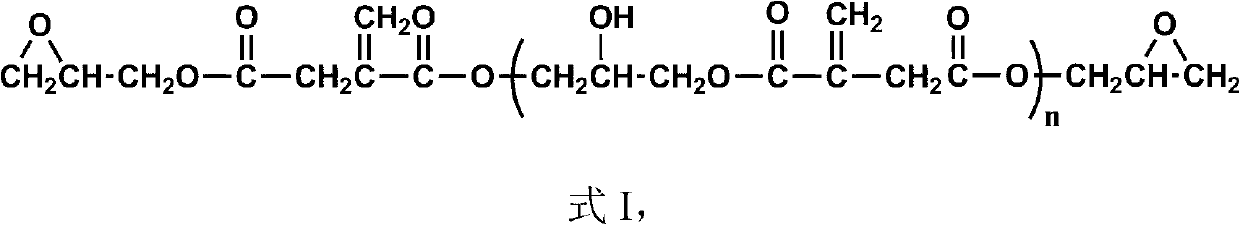

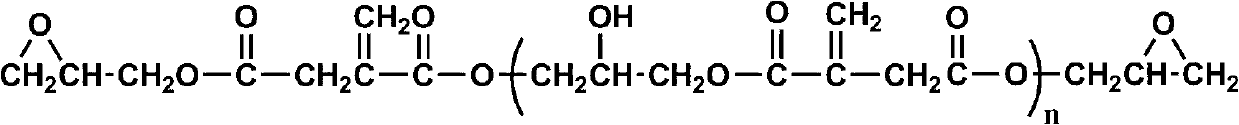

[0056] (1) Mix 100g of itaconic acid, 1000g of epichlorohydrin and 3g of tetrabutylammonium bromide, and react at 90°C for 5 hours under the protection of nitrogen, then cool down to 60°C, add 65g of sodium hydroxide and The solution that 100g deionized water is made, continue to react for 2 hours, wash with water, remove unreacted epichlorohydrin, water etc. under reduced pressure, obtain itaconic acid-based epoxy resin, pass infrared spectrogram and hydrogen nuclear magnetic resonance spectrogram Characterization, the obtained itaconic acid-based epoxy resin is shown in the structure of formula I, the average value of n is 0.41, and the epoxy value of the itaconic acid-based epoxy resin is 0.625.

[0057] (2) 100g of itaconic acid-based epoxy resin synthesized above, 20g of polyether amine (D400), 90g of polyamide (Guangzhou Xingpengwei Trading Co., Ltd., grade 650), 10g of amidoamine (Tianjin Runsheng Chemical Trading Co., Ltd., Ancamine 2443), 1g cyclohexanone peroxide and...

Embodiment 2

[0059] (1) Mix 100g of itaconic acid, 200g of epichlorohydrin and 3g of tetrabutylammonium bromide, and react at 100°C for 4 hours under the protection of nitrogen, then cool down to 60°C, add 65g of sodium hydroxide and The solution that 100g deionized water is made, continue to react for 2 hours, wash with water, decompress and distill off unreacted epichlorohydrin, water etc., characterize by infrared spectrogram and hydrogen nuclear magnetic resonance spectrogram, obtain the compound shown in the structure of formula I Itaconic acid-based epoxy resin, the average value of n is 1.73, and the epoxy value is 0.354.

[0060] (2) Mix 100g of itaconic acid-based epoxy resin synthesized above, 17.5g of 4,4′-diaminodiphenylmethane, 2g of dibenzoyl peroxide and 20g of divinylbenzene, and first cure at 90°C 4 hours, and then cured at 130°C for 8 hours to obtain a cured product of itaconic acid-based epoxy resin. The impact strength of the cured product of itaconic acid-based epoxy r...

Embodiment 3

[0062] (1) First mix 100g of itaconic acid and 200g of chloroform evenly, then add 200g of thionyl chloride and 0.5g of pyridine and mix evenly, then react at 50°C for 5 hours under the protection of an inert gas, and distill under reduced pressure to remove Unreacted thionyl chloride and chloroform, get itaconic acid chloride; Add 500g of chloroform, 100g pyridine and 100g 2,3-glycidyl alcohol in the itaconic acid chloride, under inert gas protection, Reacted at 20°C for 6 hours, washed with water, and distilled under reduced pressure to remove the solvent to obtain diglycidyl itaconate, characterized by infrared spectrum and hydrogen nuclear magnetic resonance spectrum, the diglycidyl itaconate obtained is as shown in the structure of formula I Shown, n is 0, and the epoxy value is 0.825. In the infrared spectrum, there is 2980cm -1 、1710cm -1 、1630cm -1 、1030cm -1 and other characteristic absorption peaks; 1 H NMR (CD 3 Cl is the solvent), there are characteristic che...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com