Light-emitting diode (LED)-ultraviolet (UV) area light source curing outdoor silk screen printing ink composition and preparation method thereof

A technology of screen printing ink and composition, which is applied in the field of LED-UV surface light source light curing outdoor screen printing ink composition, can solve the problems of large volume, increased surface temperature, large amount of ozone, etc., and achieves good coating performance and curing speed. Fast, high-gloss results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

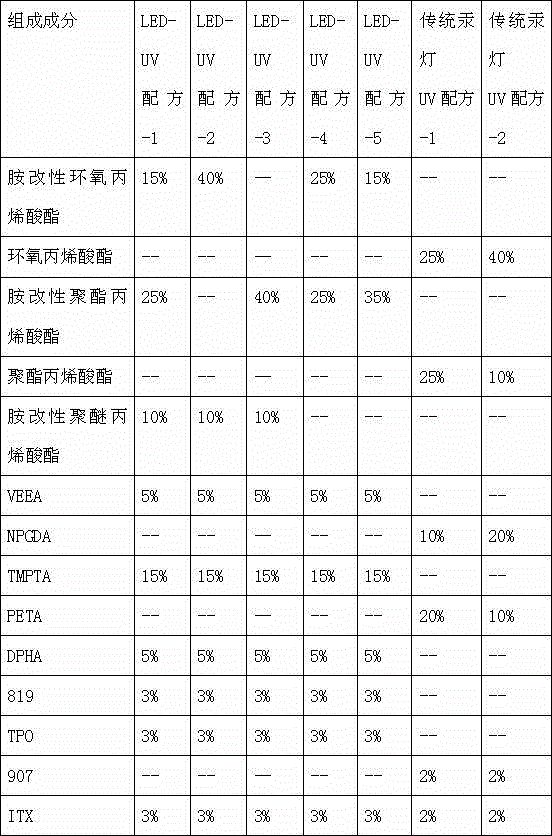

[0029] LED-UV surface light source curing, outdoor advertising screen printing, light fast four-color red ink composition and its preparation method:

[0030] Wherein each component of composition and proportioning thereof are as follows:

[0031] Amine modified epoxy acrylate resin 15%,

[0032] Amine-modified polyester acrylate resin 25%,

[0033] Amine-modified polyether acrylate resin 10%,

[0034] VEEA: 2-(vinylethoxy) ethyl diacrylate monomer 5%,

[0035] TMPTA: Trimethylolpropane Triacrylate Monomer 15%,

[0036] DPHA: dipentaerythritol hexaacrylate monomer 5%,

[0037] 819: Phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide 3%,

[0038] TPO: 2,4,6 (trimethylbenzoyl) diphenylphosphine oxide 3%,

[0039] ITX: 2-Isopropylthioxanthone 3%,

[0040] EPD: ethyl 4-dimethylamino-benzoate 3%,

[0041] NPAL: tris(N-nitroso-N-phenylhydroxylamine) aluminum salt 0.1%,

[0042] Talc powder (the main component is magnesium silicate, the fineness requirement is 2500-5000 mesh) 1...

Embodiment 2

[0055] Composition and preparation method of LED-UV surface light source curing four-color yellow ink for outdoor advertising screen printing:

[0056] Each component and proportion are as follows:

[0057] Amine modified epoxy acrylate resin 25%,

[0058] Amine-modified polyester acrylate resin 15%,

[0059] Amine modified polyether acrylate resin 5%,

[0060] VEEA: 2-(vinyl ethoxy) ethyl diacrylate monomer 10%,

[0061] TMPTA: Trimethylolpropane triacrylate monomer 15%,

[0062] 819: Phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide 2%,

[0063] TPO: 2,4,6 (trimethylbenzoyl) diphenylphosphine oxide 4%,

[0064] ITX: 2-Isopropylthioxanthone 2%,

[0065] EPD: 4-dimethylamino-benzoic acid ethyl ester 4%,

[0066] NPAL: Tris(N-nitroso-N-phenylhydroxylamine) aluminum salt 0.05%,

[0067] Talc powder (the main component is magnesium silicate, the fineness requirement is 2500-5000 mesh) 7.5%,

[0068] AF 30 or AF 29: PE polyethylene micronized wax 0.2%,

[0069] Tego...

Embodiment 3

[0086] Composition and preparation method of LED-UV surface light source curing four-color blue ink for outdoor advertising screen printing and light fastness:

[0087] The proportions of each component of the composition are as follows:

[0088] Amine modified epoxy acrylate resin 21%,

[0089] Amine-modified polyester acrylate resin 21%,

[0090] Amine modified polyether acrylate resin 8%,

[0091] VEEA: 2-(vinylethoxy) ethyl diacrylate monomer 2%,

[0092] TMPTA: Trimethylolpropane Triacrylate Monomer 15%,

[0093] DPHA: Dipentaerythritol Hexaacrylate Monomer 8%,

[0094] 819: Phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide 4%,

[0095] TPO: 2,4,6(trimethylbenzoyl)diphenylphosphine oxide 2%,

[0096] ITX: 2-Isopropylthioxanthone 4%,

[0097] EPD: ethyl 4-dimethylamino-benzoate 2%,

[0098] NPAL: tris(N-nitroso-N-phenylhydroxylamine) aluminum salt 0.08%,

[0099] Talc powder (the main component is magnesium silicate, the fineness requirement is 2500-5000 mesh)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com