Fluorescent light-emitting material and preparation method thereof

A luminescent material and fluorescent technology, which is applied in the field of fluorescent luminescent materials and their preparation, can solve the problems of low light efficiency of white light, and achieve the effects of high luminous efficiency, good dispersion and stability, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention also discloses a method for preparing a fluorescent light-emitting material, which includes the following steps:

[0031] In an inert gas atmosphere, the Cd-containing compound, the In-containing compound, the sulfur powder and the organic coating agent react in liquid olefin to obtain a fluorescent light-emitting material with an atomic ratio shown in formula (I):

[0032] CD x InS 1.5+x (I);

[0033] Among them, 0

[0034] The present invention uses a compound containing Cd, a compound containing In and sulfur powder as raw materials, and the compound containing Cd is preferably one or more of cadmium nitrate, cadmium chloride, cadmium iodide, cadmium acetate and cadmium acetylacetonate .

[0035] The compound containing In is preferably one or more of indium nitrate, indium chloride, indium iodide, indium acetate and indium acetylacetonate.

[0036] In the present invention, t...

Embodiment 1

[0046] Add 40mmol of sulfur powder into 80mL of 1-octadecene, and ultrasonically disperse at room temperature to dissolve the sulfur powder in 1-octadecene to obtain a sulfur solution;

[0047]Add 0.02mmol of cadmium acetate, 0.1mmol of indium acetate, and 0.4mmol of oleic acid into 4mL of 1-octadecene, and heat to 190°C under the protection of nitrogen to dissolve to form a transparent solution;

[0048] Seal the above transparent solution, use nitrogen to remove the air, and heat to 240°C under the protection of nitrogen, keep it for 10 minutes, add 0.3mL of sulfur solution to react for 3 minutes, and cool to room temperature to obtain a fluorescent light-emitting material, the atomic ratio of which is Cd0. 2InS1.7.

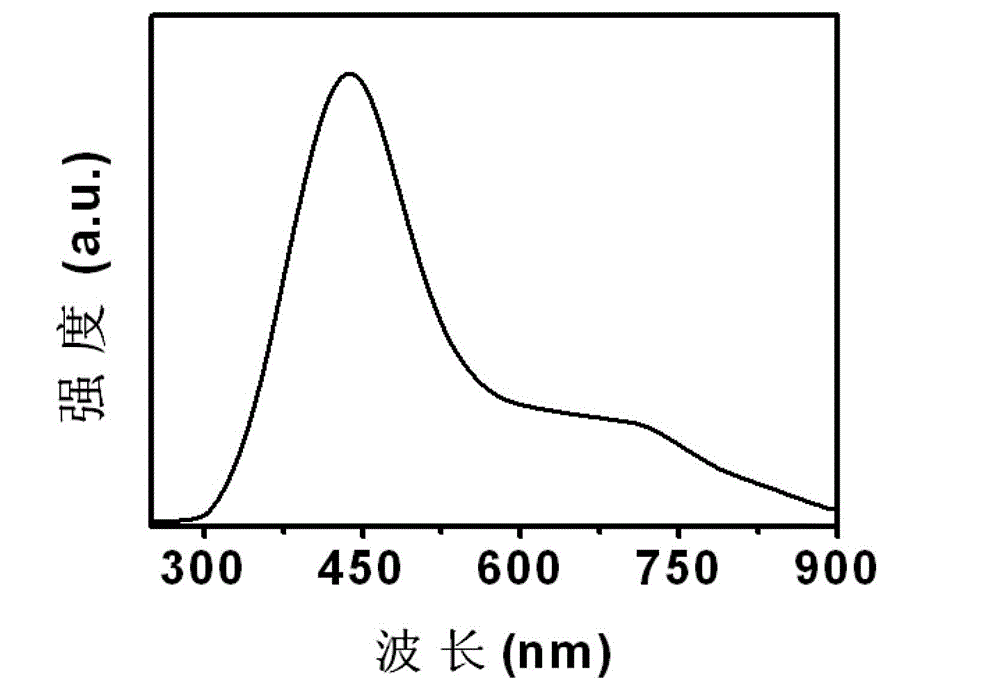

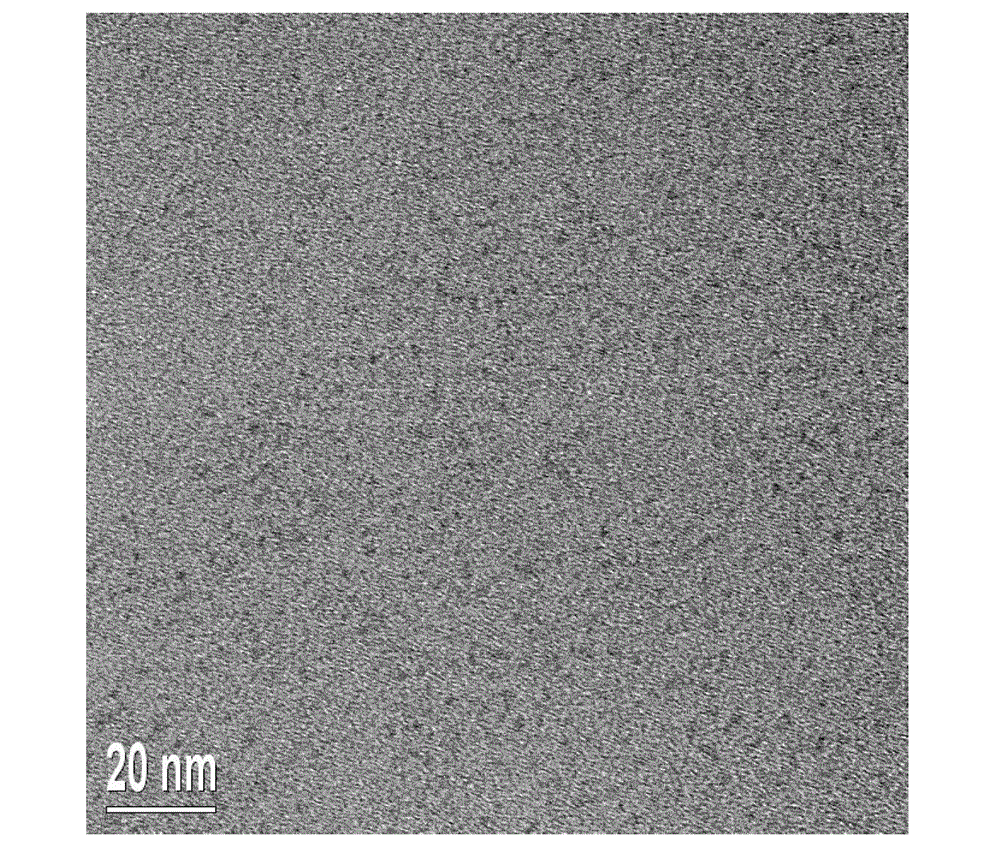

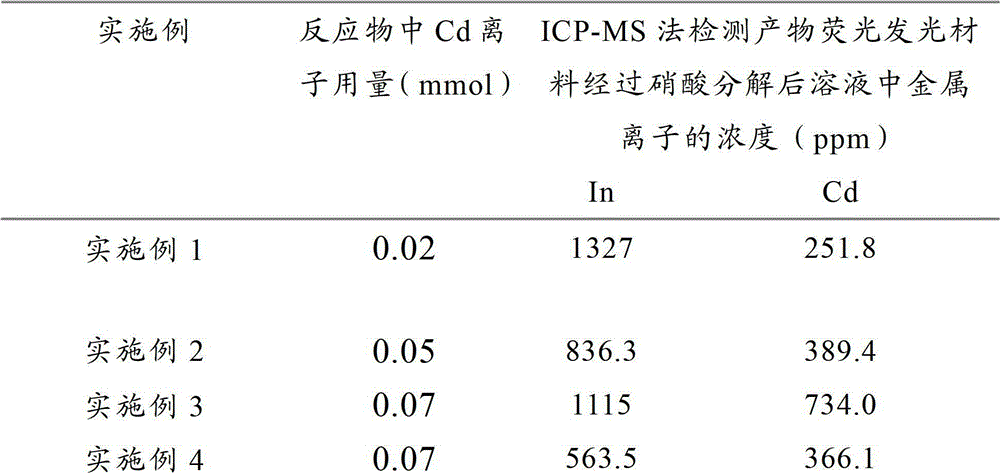

[0049] The metal content in the fluorescent luminescent material prepared in Example 1 was measured by inductively coupled plasma mass spectrometry (ICP-MS), and the results are shown in Table 1. It can be seen that the fluorescent luminescent material was prep...

Embodiment 2

[0054] Add 40mmol of sulfur powder into 80mL of 1-octadecene, and ultrasonically disperse at room temperature to dissolve the sulfur powder in 1-octadecene to obtain a sulfur solution;

[0055] Add 0.05mmol of cadmium acetate, 0.1mmol of indium acetate, and 0.4mmol of oleic acid into 4mL of 1-octadecene, and heat to 190°C under the protection of nitrogen to dissolve to form a transparent solution;

[0056] Seal the above transparent solution, use nitrogen to remove the air, and heat to 240°C under the protection of nitrogen, keep it for 10 minutes, add 0.4mL sulfur solution to react for 3 minutes, and cool to room temperature to obtain a fluorescent light-emitting material, the atomic ratio of which is Cd 0.5 InS 2 .

[0057] The metal content in the fluorescent luminescent material prepared in Example 2 was measured by inductively coupled plasma mass spectrometry (ICP-MS), and the results are shown in Table 1. It can be seen that the fluorescent luminescent material was prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| spectroscopy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com