Method for preparing vegetable protein small peptide by microoprganism fermentation

A microbial fermentation and plant protein technology, which is applied in the field of microbial fermentation to produce small plant protein peptides, can solve the problems of low utilization of active ingredients and achieve reliable and stable process parameters, mature technology, and mild fermentation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

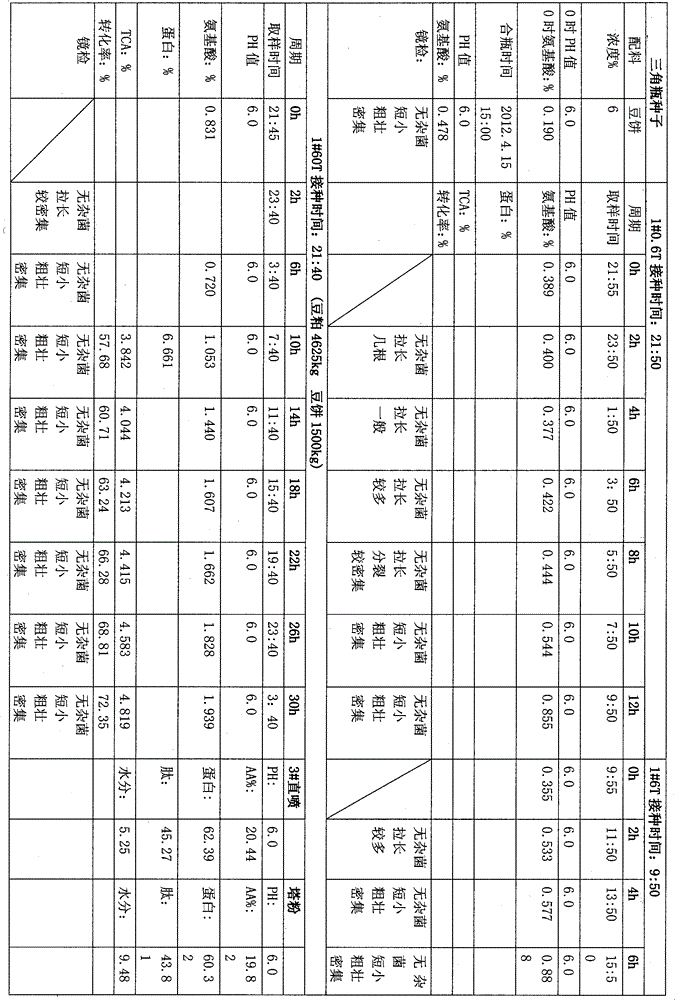

Embodiment 1

[0022] Preparation of slant medium and culture of bacteria:

[0023] By weight percentage, beef extract 2.0%, peptone 1.0%, NaCl 0.2%, agar 1.5%, water as solvent, pH 7.0. Sterilize at 121°C for 20 minutes, place it on an inclined plane to cool, and incubate at 37°C for 24 hours after inoculation ,spare.

[0024] Preparation of Erlenmeyer flask liquid medium and strain culture:

[0025] Soybean meal 6.0%, corn steep liquor 1.5%, KH 2 PO 4 0.1%, MgSO 4 0.05%, NaCl 0.2%, stir evenly, pH7.0. Sterilize at 121°C for 20 minutes, cool to 35°C, inoculate Bacillus subtilis strains, and culture on a shaker at 37°C for 24 hours, for fermenter inoculation.

[0026] Preparation of fermenter medium and fermentation control:

[0027] First crush the raw material of soybean meal to 60 mesh, add water to prepare the concentration of 10% by weight, adjust the pH value to 7.0, then sterilize at 121°C for 20 minutes, cool to 37°C, insert and cultivate mature Bacillus subtilis liquid strain....

Embodiment 2

[0030] The preparation of the slant medium and the culture of the bacteria, the preparation of the liquid medium of the Erlenmeyer flask and the culture of the bacteria are the same as the example one.

[0031] Preparation of fermentor medium and fermentation control:

[0032] First crush the raw material of rapeseed meal to 60 mesh, add water to prepare the concentration of 12% by weight, adjust the pH value to 7.2, then sterilize at 121°C for 20 minutes, cool to 35°C, and insert and cultivate it to mature at 10.0% by volume liquid strain of Bacillus subtilis. Put sterile air into the fermenter to carry out stirring and fermentation. 6 hours before fermentation, the stirring speed is 80rpm, the fermentation is 6 hours to 24 hours, the stirring speed is 150rpm, after the fermentation is 24 hours, the stirring speed is 100rpm, during this period. Adjust the ventilation volume of sterile air. During the fermentation, the temperature was controlled at 35°C, and the fermentation...

Embodiment 3

[0035] The preparation of the slant medium and the culture of the bacteria, the preparation of the liquid medium of the Erlenmeyer flask and the culture of the bacteria are the same as the example one.

[0036] Preparation of fermentor medium and fermentation control:

[0037] Weigh corn gluten powder, add water to prepare a concentration of 12% by weight, adjust the pH value to 7.2, then sterilize at 121°C for 20 minutes, cool to 37°C, and insert the cultured mature Bacillus subtilis liquid at 8.0% by volume strains. Put sterile air into the fermenter to carry out stirring and fermentation. 6 hours before fermentation, the stirring speed is 80rpm, the fermentation is 6 hours to 24 hours, the stirring speed is 150rpm, after the fermentation is 24 hours, the stirring speed is 100rpm, during this period. Adjust the ventilation volume of sterile air. During the fermentation, the temperature was controlled at 37° C., and the fermentation period was 32 hours.

[0038]After the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com