Plasma omnibearing ion deposition equipment

A technology of ion deposition and plasma, applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problems of coating cracking, large internal stress, brittle cracking, etc., and achieve the improvement of coating rate, density and Enhanced binding force and reduced internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

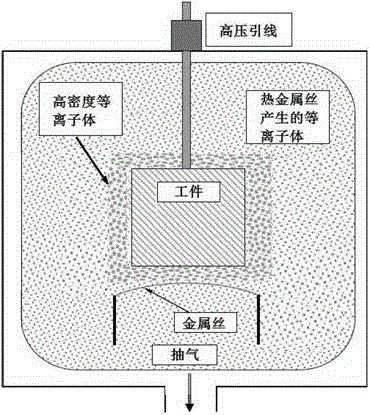

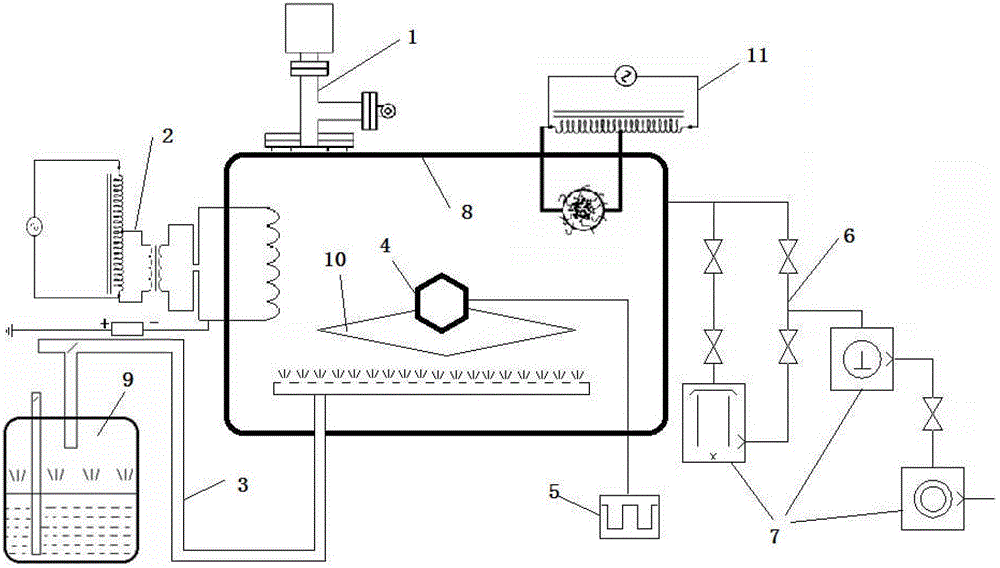

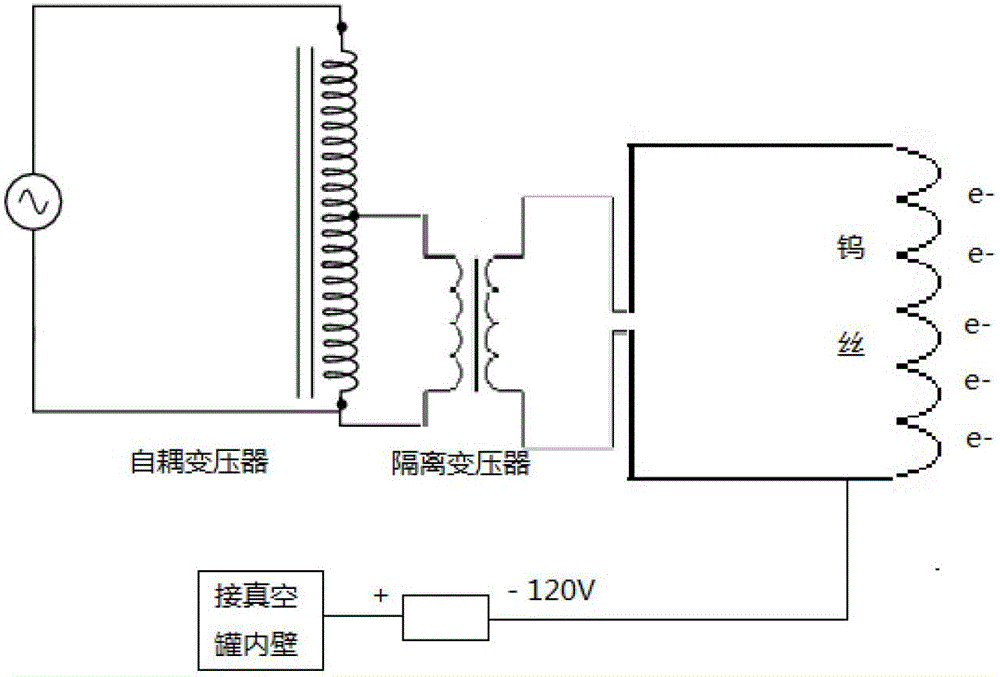

[0030] like figure 1 As shown, the plasma omni-directional ion deposition equipment includes a known vacuum coating chamber 8, an air pumping system 7, a man-machine control system 6, an air charging system 3, a vacuum detection system 1 and a high-voltage power supply system 5, wherein the high-voltage power supply system consists of an IGBT inverter Composed of variable bridge, high-frequency transformer, DC power supply PCB board, filter inductor, signal original end PCB board, pull-down drive and frequency sampling board, pulse signal isolation magnetic ring, the vacuum coating chamber is provided with an insulating support 10 for placing the coating workpiece 4, The equipment is also provided with a plasma enhancement device 2. The plasma enhancement device is composed of a metal wire located in the vacuum coating chamber and a power supply device. The metal wire is a metal material with a high melting point, such as tungsten wire and tantalum wire; It consists of an auto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com