Positive active material for rechargeable magnesium battery and rechargeable magnesium battery

A positive electrode active material, magnesium secondary battery technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve problems such as failure to meet the characteristics of secondary batteries, slow development of magnesium secondary batteries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

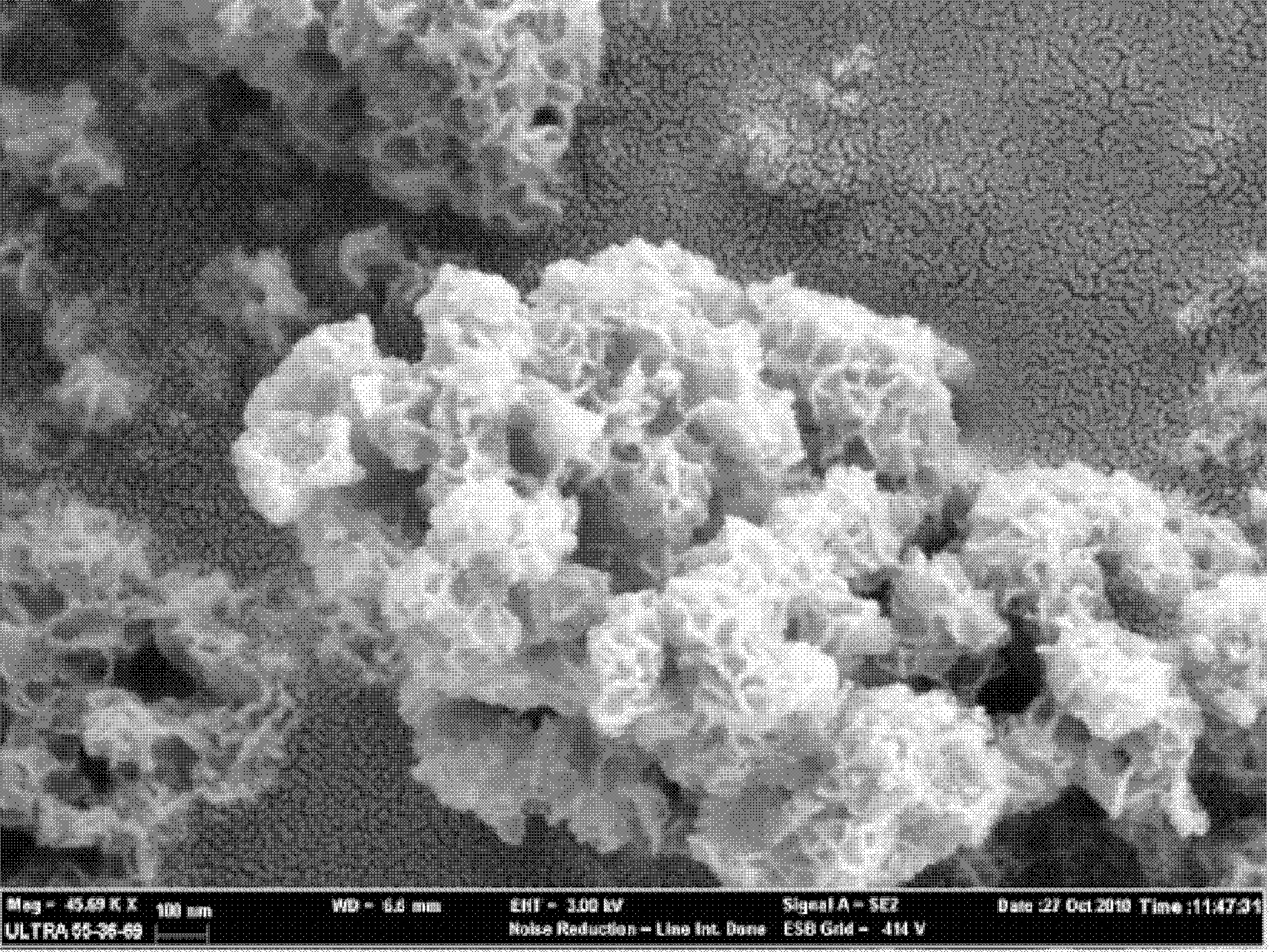

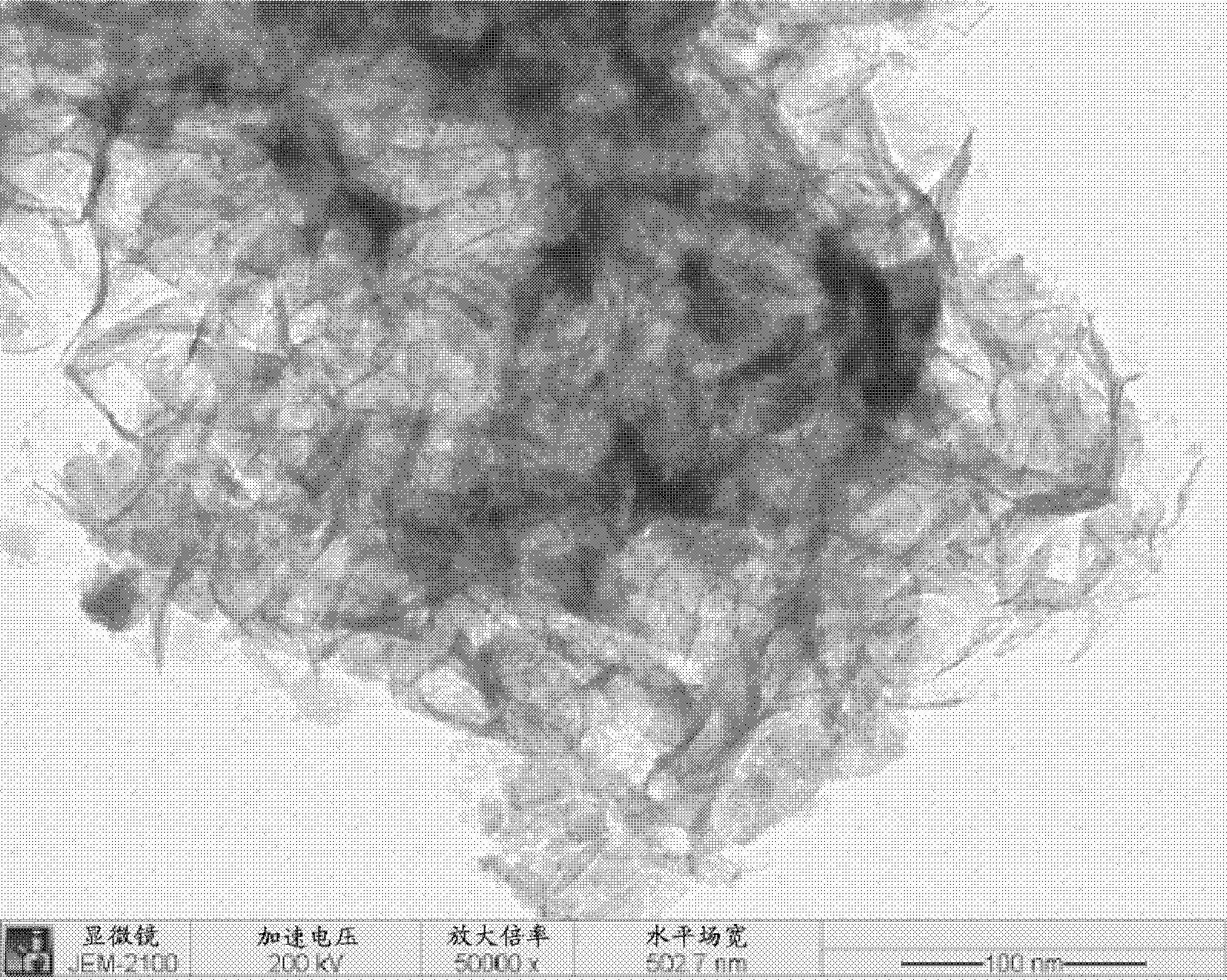

[0078] [Manufacture of cathode material by template method]

[0079]

[0080] In order to obtain the composition as described in Table 1 below, each raw material described in Table 1 was dissolved in pure water to prepare a mixed solution having a concentration of 1 mol / liter. It should be noted that the SiO described in Table 1 2 The raw material used is silicon dioxide with a particle size of 15-20nm.

[0081]

[0082] 4.2 g of polyvinylpyrrolidone (Mw=30000) was stirred and dissolved in 300 ml of ion-exchanged water, and potassium persulfate (0.14 g) and 31.5 mL of styrene were further added. Argon gas was blown into the obtained mixed solution at room temperature for 1 hour to deoxidize, and then, it was heated to 70° C. and polymerized in an argon atmosphere for 24 hours. Then, it was centrifuged for 30 minutes to arrange the synthesized monodisperse polystyrene (PS) spherical powder into colloid crystals, and dried at 50°C for 24 hours. Further, the PS spheres wer...

Embodiment 2

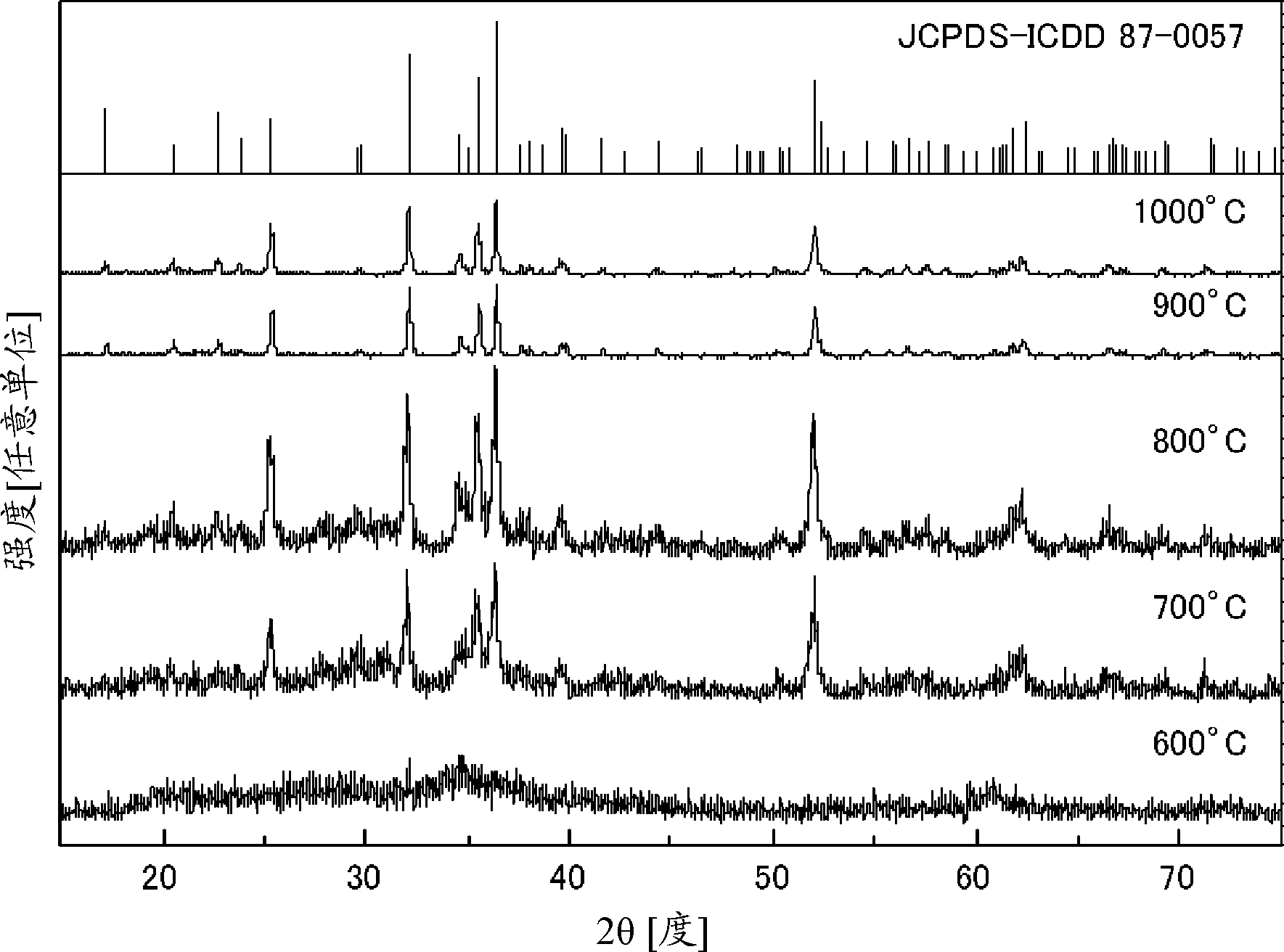

[0098] [Manufacture of positive electrode active material by spray pyrolysis method]

[0099] In order to obtain the composition as described in Table 2 below, the raw materials described in Table 2 were dissolved in pure water to prepare a raw material solution having a concentration of 0.6 mol / liter.

[0100] The prepared mixed solution was formed into fine droplets using an ultrasonic nebulizer, and air was used as a carrier gas to carry out thermal decomposition by spraying in an electric furnace heated to 600°C, and the product was recovered.

[0101] Then, use methanol as a dispersion medium, utilize planetary ball mill to carry out wet pulverization to the product obtained, and according to the atmosphere and temperature described in the following table 2, carry out heat treatment for 4 hours, thereby obtain the sample 2-1~ 2-7. In the same manner as in Example 1, carbon coating treatment was performed on each of the obtained samples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com