TM mode harmonic oscillator and preparation method thereof

A technology of harmonic oscillators and rotating shafts, applied in the field of TM mode harmonic oscillators and its preparation, can solve the problems of lowering the resonance frequency and failing to increase the dielectric constant, and achieve the effect of reducing the volume, reducing the loss, and increasing the dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

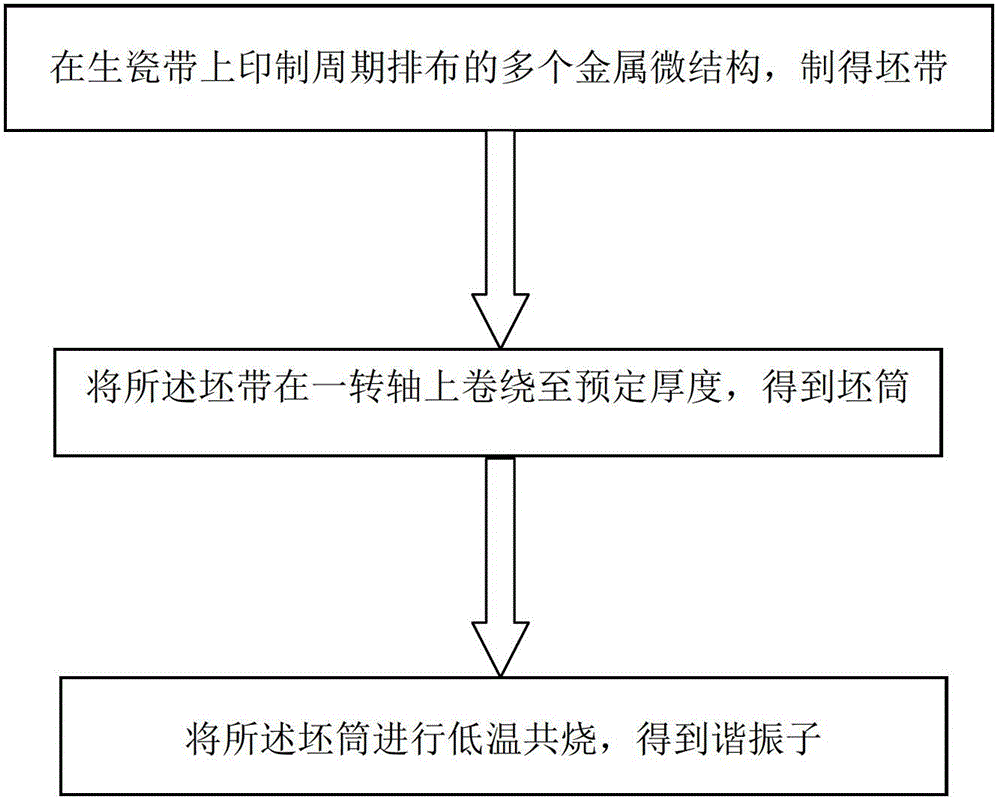

[0033] First manufacture the blank belt, the specific process is as follows:

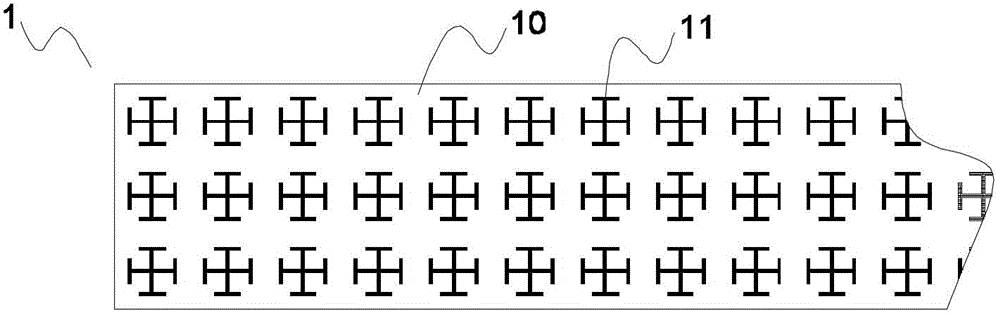

[0034] The raw porcelain tape is made by tape casting or can be purchased directly in the market, and the thickness is 100-500 μm. Such as figure 2 As shown, a green ceramic tape 10 is used as a printing substrate, and a metal microstructure 11 is printed on it by a screen printing process to obtain a blank tape 1 .

[0035] The composition of the metal microstructure 11 can be various metal pastes used in the existing low-temperature co-firing process, in this embodiment, it is silver, and each metal microstructure 11 includes a cross shape formed by two mutually perpendicular silver lines The structure and the inline structure connected to the four ends of the cross-shaped structure form a symmetrical structure as a whole.

[0036] The metal microstructures 11 are arranged in a rectangular array on the green ceramic tape 10, and the row pitch (the distance between the center points of two adjac...

no. 2 example

[0044] To manufacture the green tape, the steps are exactly the same as those in the first embodiment, and the green tape 1 printed with the metal microstructure is obtained.

[0045] The specific process of manufacturing the billet is as follows:

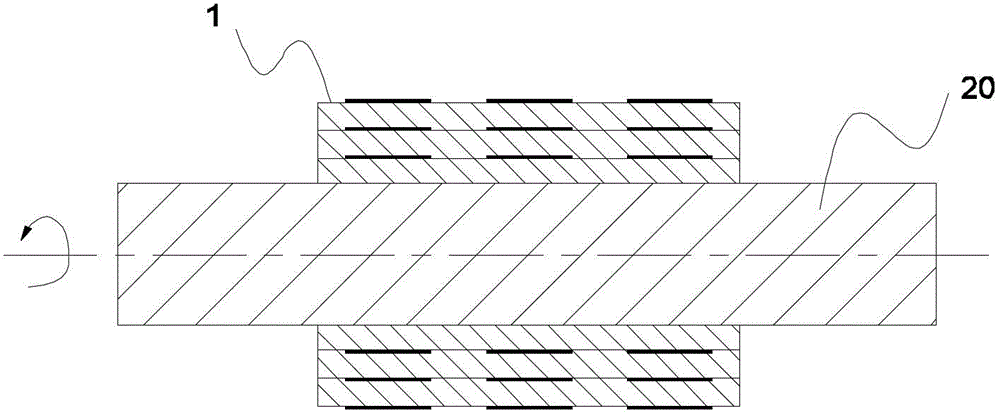

[0046] After making blank strip 1, such as image 3 As shown, the base strip 1 is wound into a cylindrical base 2 on a cylindrical rotating shaft 20 under a certain pressure. In this embodiment, the rotating shaft 20 is made of organic material, and the organic material here is polytetrafluoroethylene, polyethylene, polypropylene, polystyrene or polymethyl methacrylate, etc., which have certain mechanical strength at room temperature. It is a material that resists the pressure caused by the winding of the blank 1 to prevent deformation, and can be burned or decomposed completely after heating before reaching 800 degrees Celsius.

[0047] Then sintering, the specific process is as follows:

[0048]Cold isostatic pressing is carri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com