Preparation method and application of modified orange peel biological adsorbent

A technology of biological adsorbent and orange peel is applied in the field of preparation of modified orange peel biological adsorbent, and can solve the problems of heavy metal-containing wastewater pollution and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] a. Collect orange peel waste from orange orchards or food factories, after cleaning, drying, grinding and sieving, add to the mixed solution of absolute ethanol and 2.5mol / L NaOH with a volume ratio of 1:1, and then add Epichlorohydrin is refluxed for 1-3 hours to obtain epichlorohydrin cross-linked orange peel;

[0022] b. The catalyst is sodium bicarbonate and modifier cysteine, and step a epichlorohydrin cross-linked orange peel is continuously stirred at a temperature of 50° C. for 4 hours;

[0023] c. After the reaction is completed, the reactants are washed and dried to obtain the cysteine-modified orange peel biosorbent.

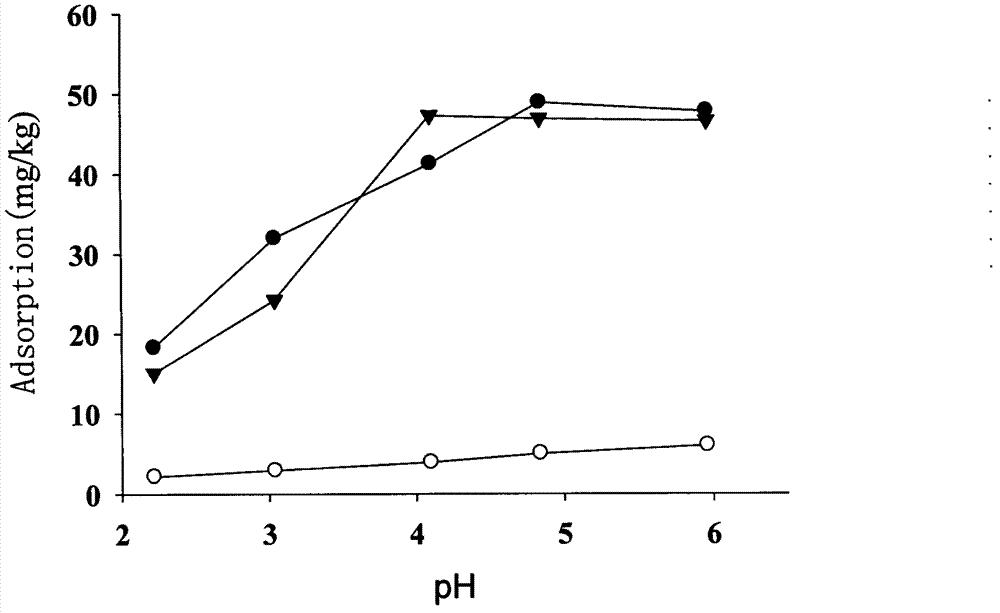

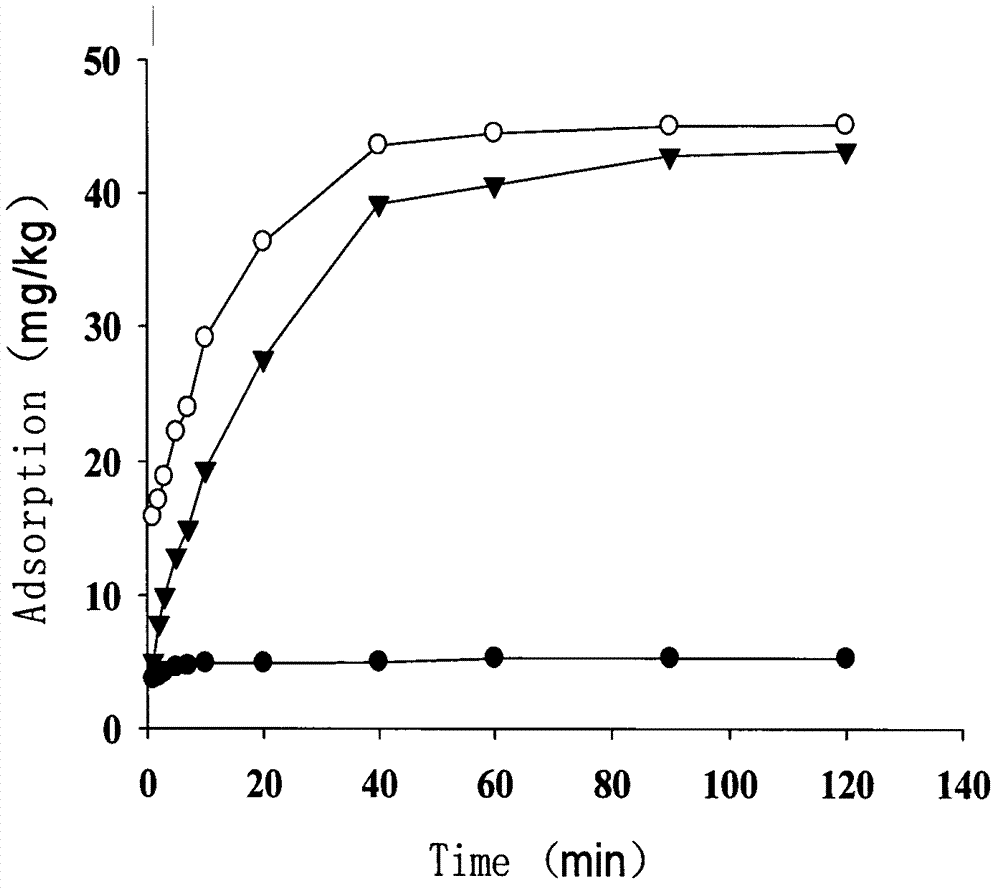

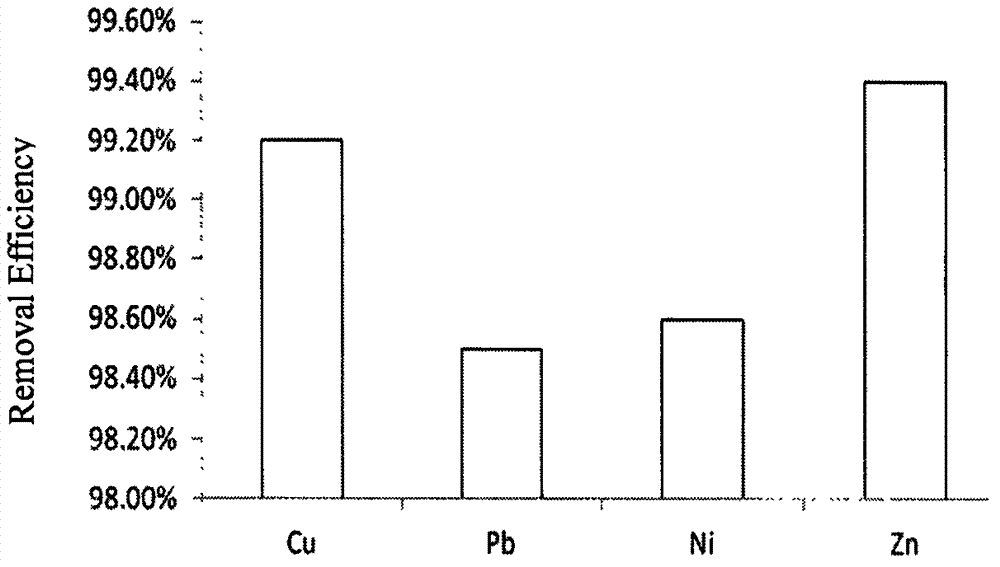

[0024] The cysteine modified orange peel biosorbent obtained by this method has a pH value of 2.0-6.0, heavy metal Cu 2+ The waste water is added to the reactor, and it is fully mixed at room temperature to carry out the adsorption reaction for 2 hours. After the reaction is completed, the solid-liquid separation is carried out. The solid ad...

Embodiment 2

[0026] a. Collect orange peel waste from orange orchards or food factories, after cleaning, drying, grinding and sieving, add to the mixed solution of absolute ethanol and 2.5mol / L NaOH with a volume ratio of 1:1, and then add Epichlorohydrin is carried out reflux reaction, time 1 hour, obtains epichlorohydrin cross-linked orange peel;

[0027] b. The catalyst is sodium bicarbonate and modifier cysteine, and step a epichlorohydrin cross-linked orange peel is continuously stirred at a temperature of 50° C. for 4 hours;

[0028] c. After the reaction is completed, the reactants are washed and dried to obtain the cysteine-modified orange peel biosorbent.

[0029] The cysteine modified orange peel biosorbent obtained by this method has a pH value of 2.0-6.0, heavy metal Pb 2+ The waste water is added to the reactor, and it is fully mixed at room temperature to carry out the adsorption reaction for 2 minutes. After the reaction is completed, the solid-liquid is separated, and th...

Embodiment 3

[0031] a. Collect orange peel waste from orange orchards or food factories, after cleaning, drying, grinding and sieving, add to the mixed solution of absolute ethanol and 2.5mol / L NaOH with a volume ratio of 1:1, and then add The epichlorohydrin was refluxed for 3 hours to obtain the epichlorohydrin cross-linked orange peel;

[0032] b. The catalyst is sodium bicarbonate and the modifier diethylenetriamine and the epichlorohydrin cross-linked orange peel in step a are continuously stirred at a temperature of 50 ° C for 4 hours;

[0033] c. After the reaction is completed, the reactants are washed and dried to obtain the diethylenetriamine-modified orange peel biosorbent.

[0034] The diethylenetriamine modified orange peel biosorbent obtained by this method has a pH value of 2.0-6.0 heavy metal Ni 2+ The waste water is added to the reactor, and it is fully mixed at room temperature to carry out the adsorption reaction for 30 minutes. After the reaction is completed, the soli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com