Preparation method of SiC nanowire with expandable graphite as carbon source

A technology of expanded graphite and nanowires, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of low yield of nanowires and increased preparation cost, and achieve simple process, low energy consumption, and no catalyst. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In this embodiment, expandable graphite is used as the carbon source SiC nanowires. The steps are as follows:

[0020] 1. Mix expandable graphite with a mass fraction of 21.4%, industrial silicon powder with a mass fraction of 25% and silica powder with a mass fraction of 53.6% and grind them evenly, place them in a high-purity graphite crucible and place them at high temperature In the atmosphere box furnace;

[0021] 2. Vacuumize and fill the protective gas with nitrogen, and the pressure in the furnace during the preparation process is lower than 1MPa;

[0022] 3. The high-temperature atmosphere box furnace is raised to 1500°C, and the temperature is kept and sintered for 6 hours;

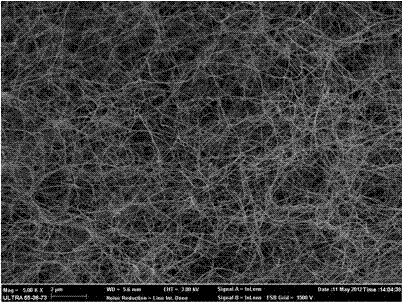

[0023] 4. Naturally cool down to room temperature with the furnace, and then open the furnace to obtain dark green SiC nanowires, such as figure 1 The nanowires shown are approximately 100 nm in diameter.

Embodiment 2

[0025] In this embodiment, expandable graphite is used as the carbon source SiC nanowires. The steps are as follows:

[0026] 1. Dissolve ethyl orthosilicate in absolute ethanol, add oxalic acid to accelerate the hydrolysis of ethyl orthosilicate, the molar ratio of ethyl orthosilicate: absolute ethanol: water is 1:0.86:4, dilute oxalic acid to 0.01mol / L. Then add expandable graphite, tetraethyl orthosilicate: the molar ratio of expandable graphite is 1:1;

[0027] 2. Prepare the mixed gel with magnetic stirring, dry the gel at 70°C for 4 hours, then rise to 90°C for 4 hours, then rise to 110°C for 4 hours; grind it into powder, put it in a high-purity graphite crucible and put it in High temperature atmosphere box furnace;

[0028] 3. Vacuumize and fill the protective gas with argon, and the pressure in the furnace during the preparation process is lower than 1MPa;

[0029] 4. The high-temperature box-type atmosphere furnace is raised to 1500°C, and the temperature is kept...

Embodiment 3

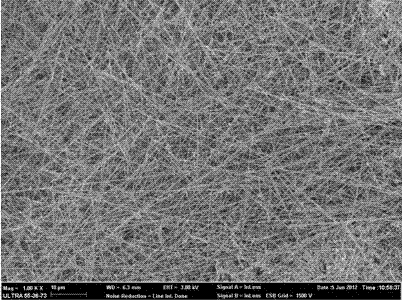

[0032] The difference between this embodiment and Example 1 is that in step 1, the mass fraction percentage is 5.2% expandable graphite, the mass fraction percentage is 30.2% industrial silicon powder and the mass fraction percentage is 64.6% The silica powder is mixed and ground evenly; In step 3 the temperature was raised to 1300°C. Other steps are identical with embodiment 1. The dark green SiC nanowires with a diameter of about 10nm were obtained immediately after firing the furnace.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com