Continuous process method for preparing hydroquinone

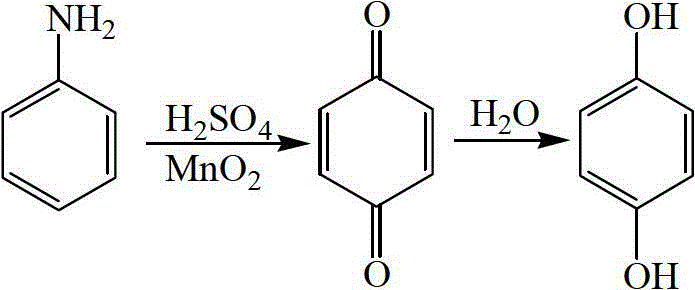

A technology of hydroquinone and a process method is applied in the field of preparation of hydroquinone, and can solve the problems of affecting the stability of hydrolyzed base acid, large amount of acid circulation in hydrolysis reaction, and high requirements on the material of hydrolysis kettle, so as to reduce equipment investment. , to achieve the effect of waste acid discharge and reduce equipment volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Diazotization reaction: Add 408g (0.625mol) of 15% sulfuric acid and 27.8g (0.25mol) of 98% p-aminophenol for industrial products into a 1000mL reactor, stir and cool down to -5~0°C, add 40% sodium nitrite dropwise Aqueous solution 48g (0.275mol), dripping time 30-45min, after dropping, keep warm for 0.5hr, add 1.5g urea, stir for 15min, when the release of nitrogen is not obvious, add 1.5g thiourea and stir for another 15min. The dropwise addition, heat preservation and feeding temperature were all kept at -5-5°C to obtain 470-480 g of dark brown diazonium liquid, which was stored at 0°C.

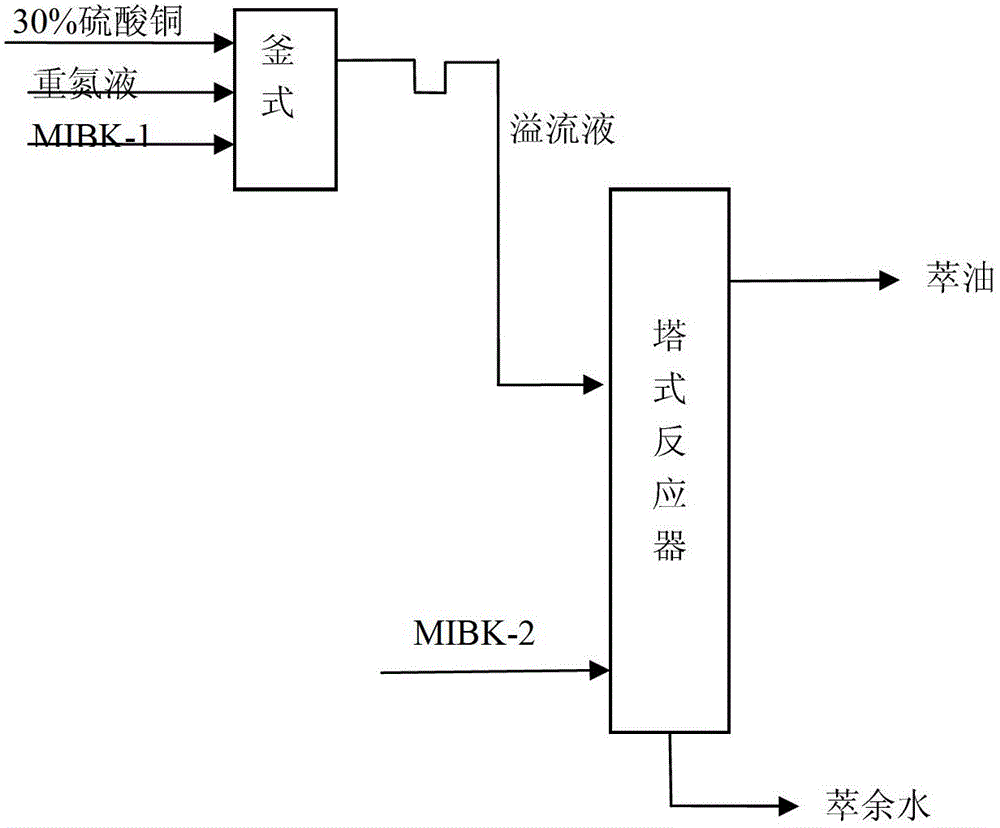

[0039] Reaction-extraction: using attached figure 1 Process, add 250g of 30% copper sulfate and 25g of MIBK into a 1000ml four-necked bottle, start stirring and raise the temperature to 85-88°C, add 235g of diazonium solution dropwise for 1hr, after the addition is completed, keep warm at 85-88°C for 2hr, and the resulting mixture is used as Bottom material for continuous tank reac...

Embodiment 2-6

[0041] The preparation method is the same as in Example 1, except that the concentration of copper sulfate in the hydrolysis is changed. The copper in the hydrolysis is all calculated in the form of copper sulfate)

[0042]

[0043] The concentration of hydrolyzed copper sulfate is higher than 30%, and the yield is 90-92%; when the yield drops to 20%, the yield shows an obvious downward trend.

Embodiment 7

[0045] Hydroquinone preparation method carries out according to the following steps:

[0046] Diazotization reaction: Add 408g (0.625mol) of 15% sulfuric acid and 27.8g (0.25mol) of 98% p-aminophenol for industrial products into a 1000mL reactor, stir and cool down to -5~0°C, add 40% sodium nitrite dropwise Aqueous solution 48g (0.275mol), dripping time 30-45min, after dropping, keep warm for 0.5hr, add 1.5g urea, stir for 15min, when the release of nitrogen is not obvious, add 1.5g thiourea and stir for another 15min. The dropwise addition, heat preservation and feeding temperature were all kept at -5-5°C to obtain 470-480 g of dark brown diazonium liquid, which was stored at 0°C.

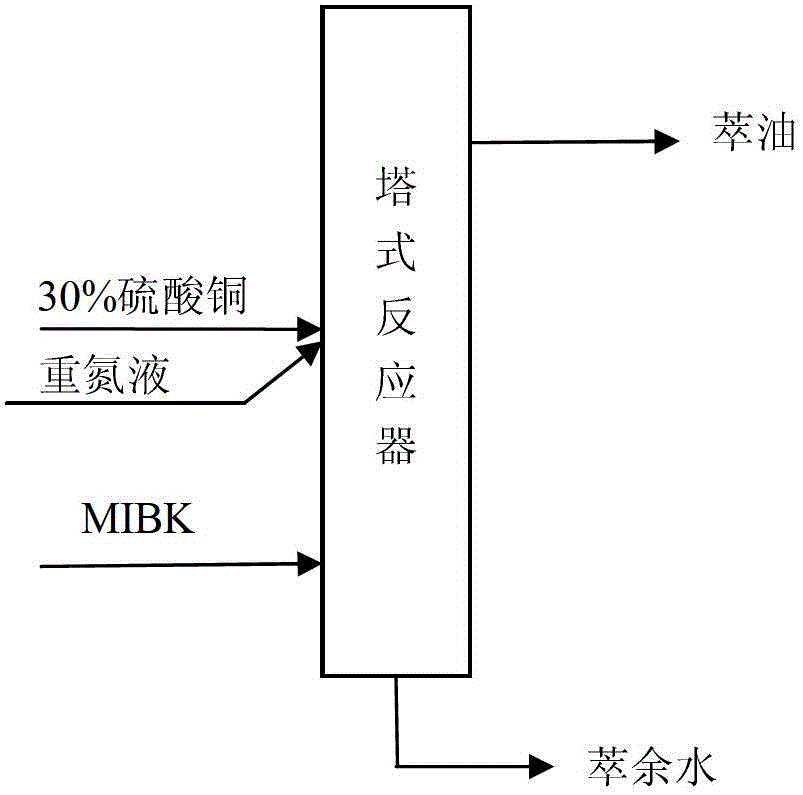

[0047] Reaction-extraction: using attached figure 2 Process, add 1700g of 30% copper sulfate solution to a tower reactor with a volume of 1300ml, preheat to 88°C; continuously feed MIBK from the bottom, with a flow rate of 77.82g / hr; feed 30% copper sulfate in the middle, with a flow rate of 194...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com