Poly(DL-lactic acid) material modified based on 24 peptides in E domain of mechano-growth factor (MGF), and preparation method and application thereof

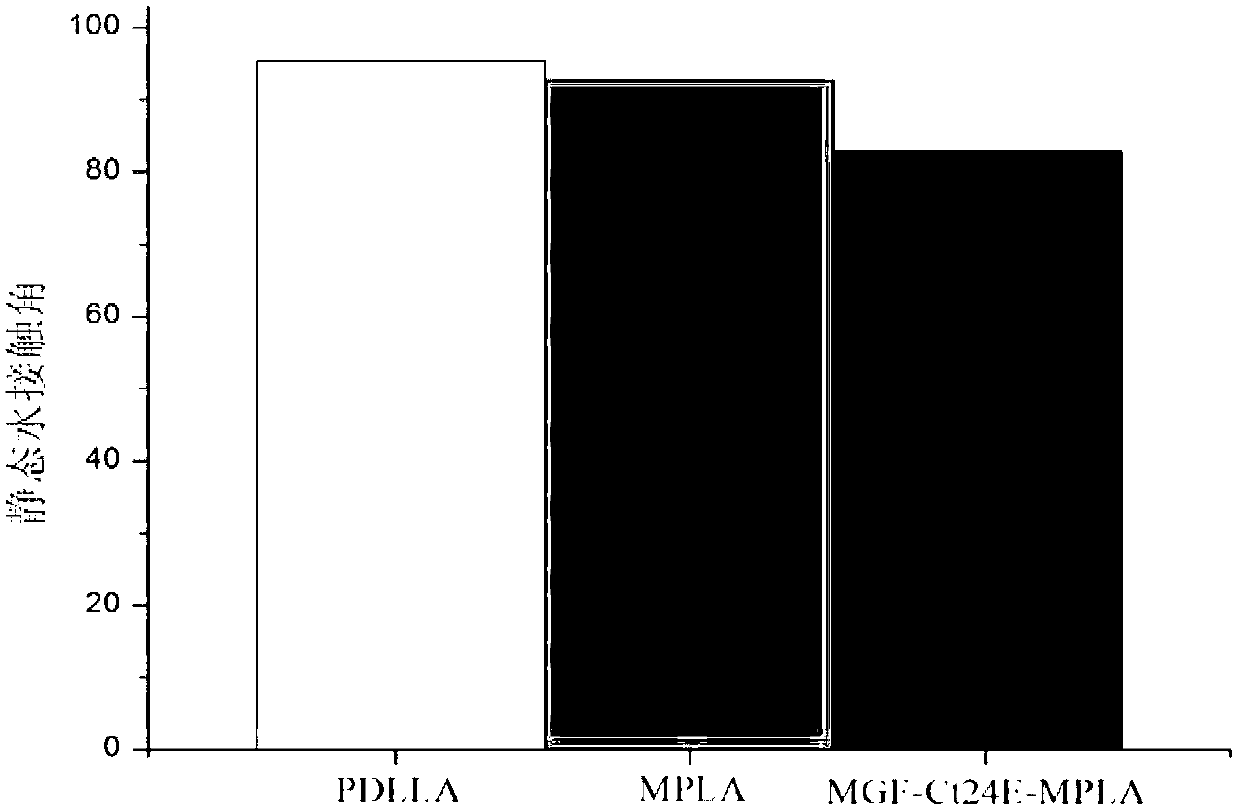

A technology of polylactic acid materials and growth factors, applied in medical science, surgery, prostheses, etc., can solve problems not specified in detail, achieve good hydrophilicity and cell affinity, relieve inflammation, promote blood vessel and bone The effect of tissue regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

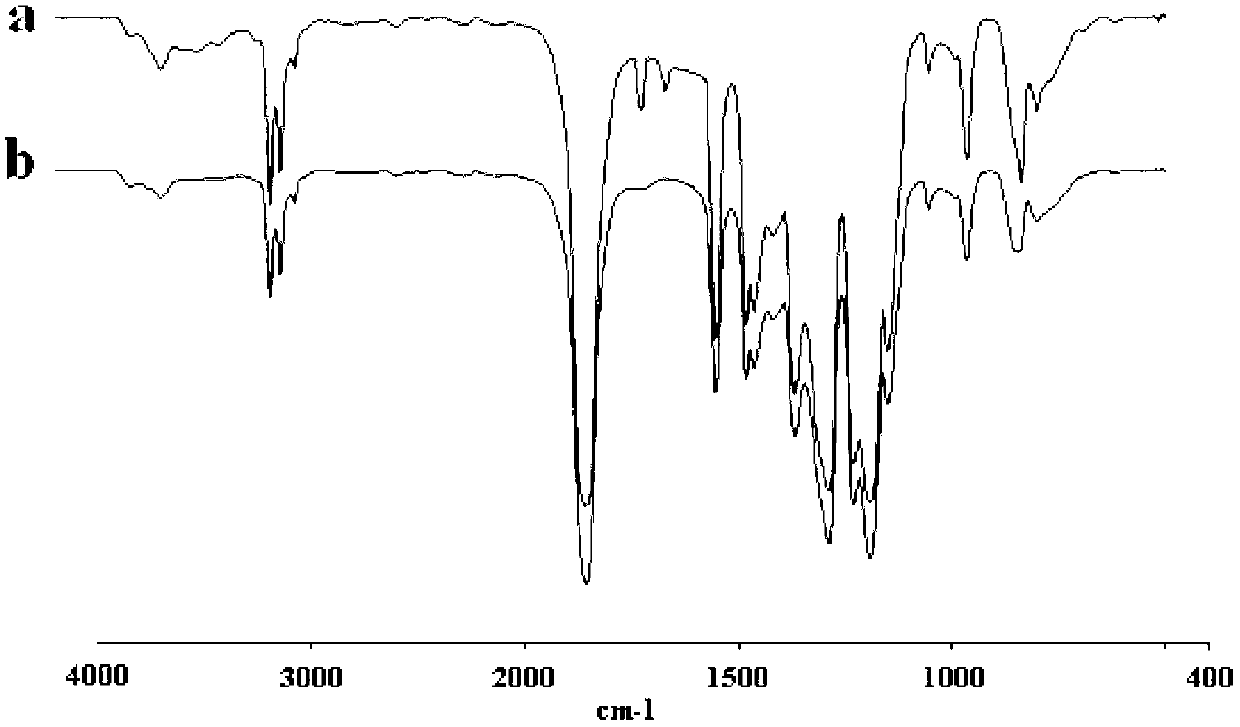

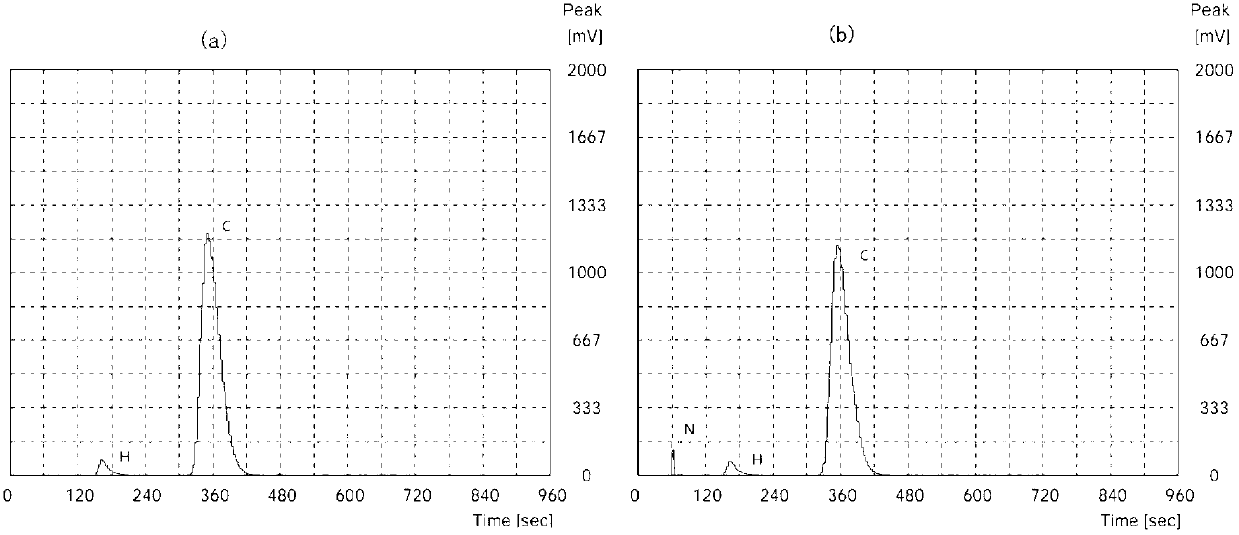

[0040] Embodiment 1 Cyclic anhydride modified polylactic acid

[0041]5.0 g of poly(D,L-lactic acid), 0.5 g of maleic anhydride, and 10 mg of tert-butyl peroxide were mixed uniformly, and vacuum melted and sealed in a 50 ml round bottom flask. React at 50°C for 24 hours to obtain brown-yellow maleic anhydride-modified polylactic acid. The product was dissolved in dichloromethane and dropped into excess ether, and the precipitate was collected. Repeat to dissolve the pellet three times. The precipitate was placed under vacuum for 48 hours at room temperature to obtain 3.8 g of brown maleic anhydride-modified polylactic acid, the molecular formula of which was as follows: Said A is D, L-lactic acid; through parallel tests: when A is D-lactic acid or L-lactic acid, it can all be realized.

[0042] Maleic acyl-modified polylactic acid is a kind of cyclic acid acyl-modified polylactic acid. For other cyclic acyl-modified polylactic acid and its preparation method, please refer...

Embodiment 2

[0043] Embodiment 2 Cyclic anhydride modified polylactic acid

[0044] 5.0 g of poly(D,L-lactic acid) (wherein n=100) and 0.5 g of maleic anhydride and 20 mg of tert-butyl peroxide were uniformly mixed, vacuum melted and sealed in a 50 ml round bottom flask. React at 50°C for 24 hours to obtain brown-yellow maleic anhydride-modified polylactic acid. The product was dissolved in dichloromethane and dropped into excess ether, and the precipitate was collected. Repeat to dissolve the pellet three times. The precipitate was irritated under vacuum at room temperature for 48 hours to obtain 3.5 grams of brown maleic anhydride-modified polylactic acid, the molecular formula is as follows: Said A is D, L-lactic acid; through parallel tests: when A is D-lactic acid or L-lactic acid, it can all be realized.

Embodiment 3

[0045] Embodiment 3 Cyclic anhydride modified polylactic acid

[0046] 5.0 g of poly(D,L-lactic acid), 0.5 g of maleic anhydride, and 30 mg of tert-butyl peroxide were evenly mixed, and vacuum melted and sealed in a 50 ml round bottom flask. React at 50°C for 24 hours to obtain brown-yellow maleic anhydride-modified polylactic acid. The product was dissolved in dichloromethane and dropped into excess ether, and the precipitate was collected. Repeat to dissolve the pellet three times. Put the precipitate under vacuum at room temperature for 48 hours to obtain 4.2 g of brown maleic anhydride-modified polylactic acid, the molecular formula is as follows The A is D, L-lactic acid. In addition, a parallel test is carried out, and it can be realized when A is D-lactic acid or L-lactic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com