Thermoplastic hydrophilic degradable waterproof moisture permeable film

A waterproof, moisture-permeable, and plastic technology, which is applied in the field of textile fabrics, can solve problems such as low heat resistance, poor heat resistance, and holes in the membrane surface, and achieve enhanced wear resistance and corrosion resistance, neat and tidy clothing, and improved respiratory function. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

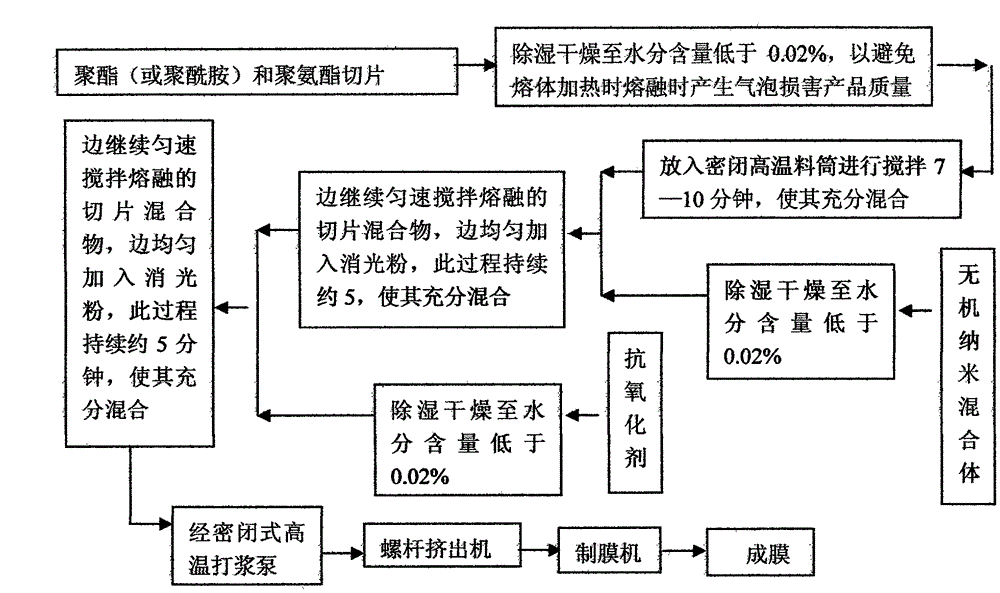

[0019] Embodiment: A thermoplastic hydrophilic degradable waterproof and moisture-permeable film, the degradable waterproof and moisture-permeable film is realized through the following process:

[0020] Step 1. Evenly mix polyester chips or polyamide chips with polyurethane chips in a mass ratio of 100:10 to form mixture chips. The polyester chips or polyamide chips are dehumidified and dried until the moisture content is lower than 0.02%, and the polyurethane chips are dehumidified and dried. to a moisture content of less than 0.02%;

[0021] Step 2, placing the mixture slices in step 1 in a high-temperature barrel and stirring and mixing at high temperature to form a molten slice mixture;

[0022] Step 3. Stir the melted slice mixture of step 2 and slowly and uniformly add nano-mixed powder composed of titanium dioxide and zinc oxide. The mixing ratio of the melted slice mixture and mixed nano-powder in step 3 is 100:2. The inorganic The nano-mixed powder (this powder play...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com