Method for culturing chlorella by heterotrophism with sludge hydrolysate

A chlorella and hydrolyzate technology, applied in microorganism-based methods, water/sludge/sewage treatment, sludge treatment, etc., can solve the problem of high cost of microalgae biodiesel, achieve resource utilization and save production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

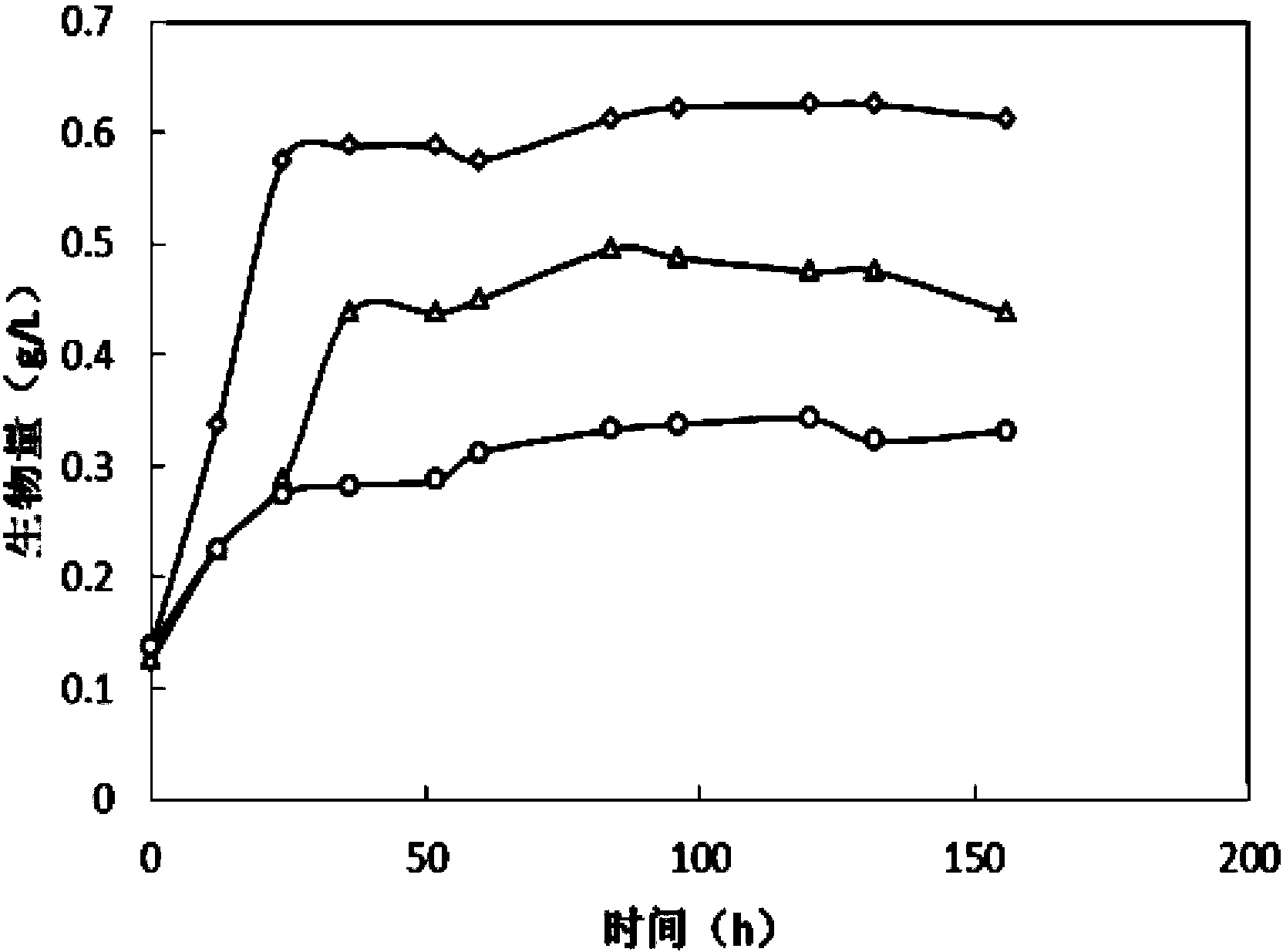

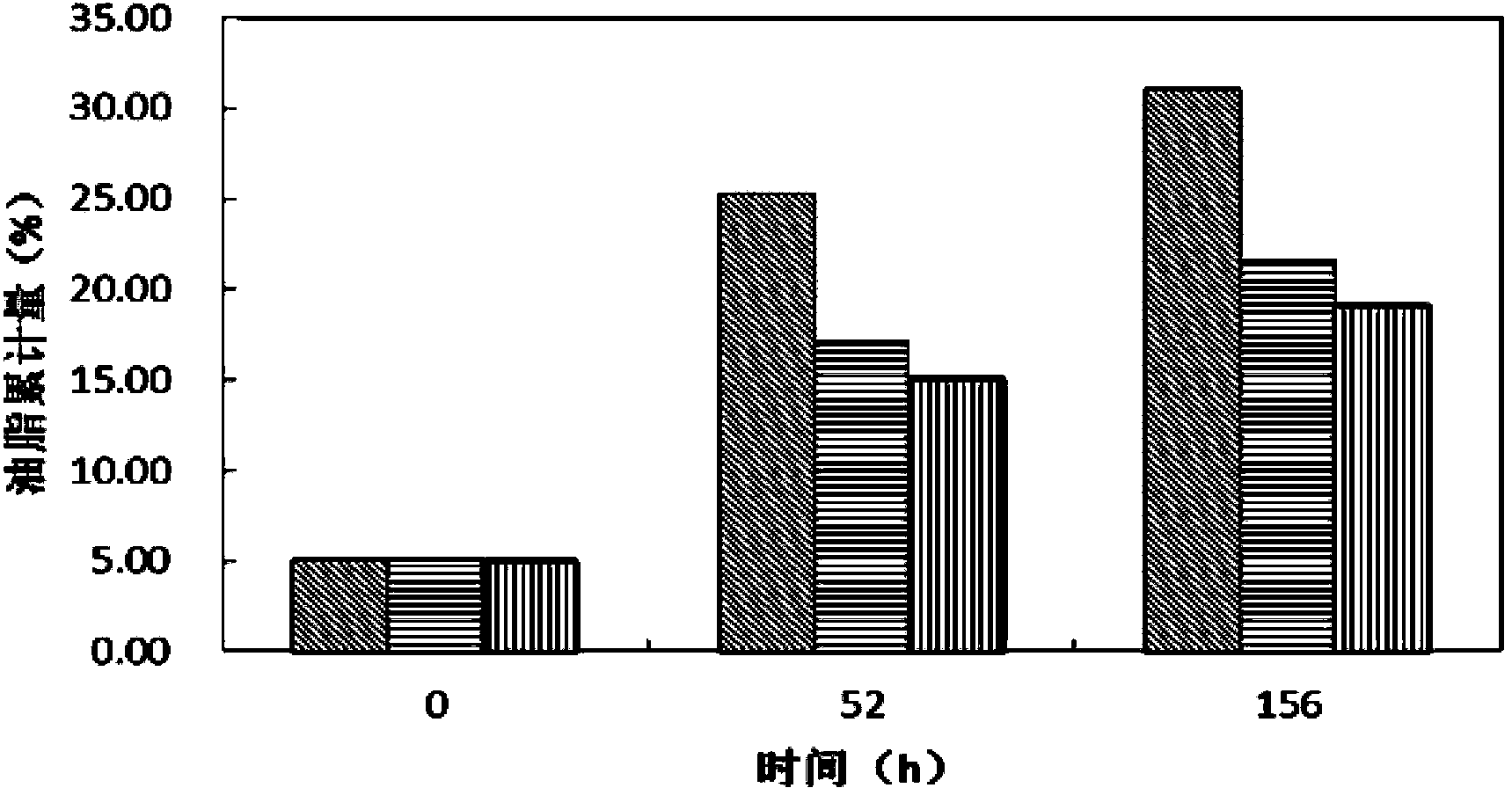

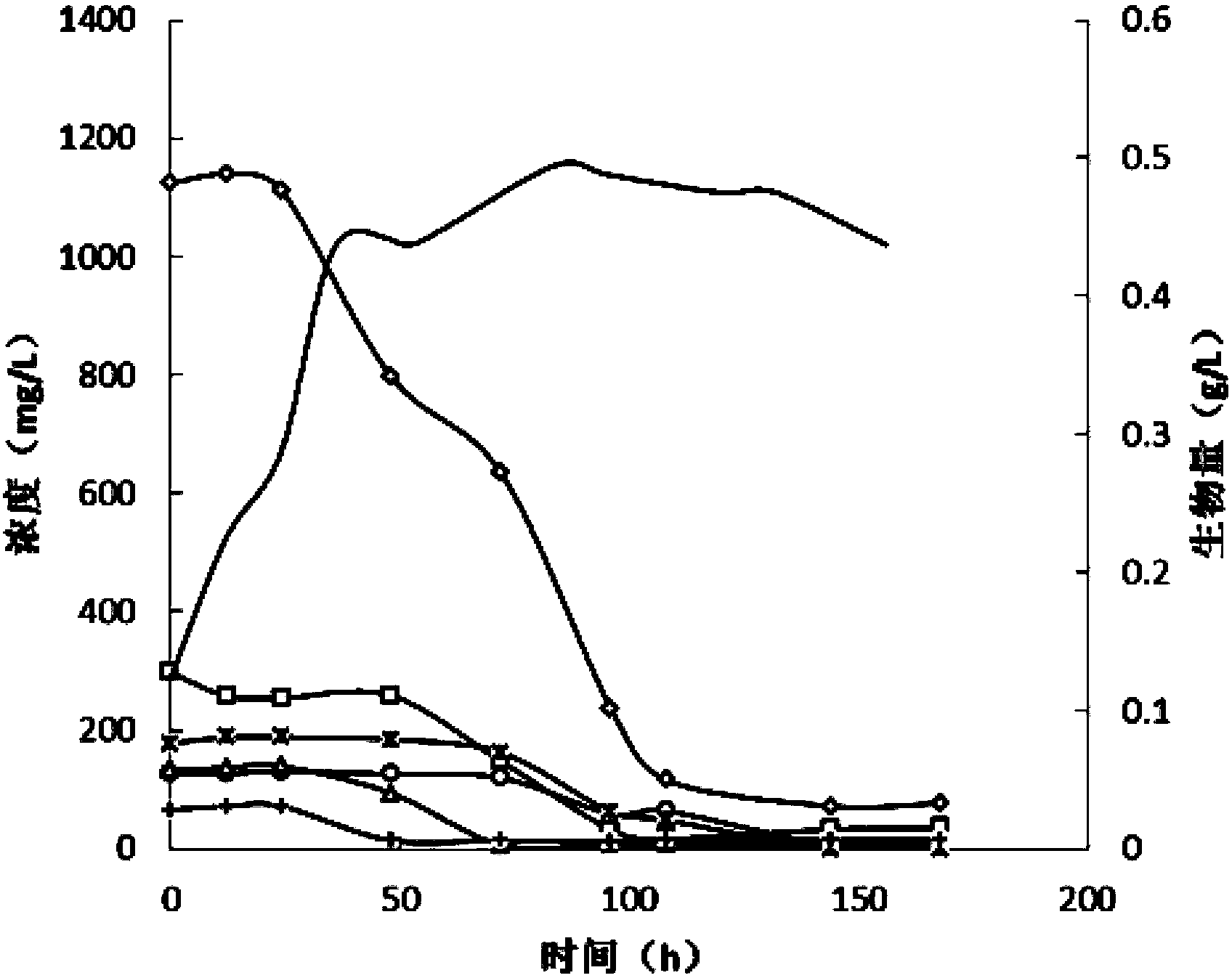

[0015] Specific embodiment one: a kind of method of utilizing sludge hydrolyzate heterotrophic culture Chlorella of the present embodiment is to carry out according to the following steps: 1, sludge ultrasonic treatment: take the remaining sludge of domestic sewage treatment plant, the sewage The moisture content of the mud is concentrated to a mass percentage of 98%~98.5%, and the ultrasonic treatment is carried out for 8~10min under the condition of an acoustic energy density of 5~10W / mL and a pulse ratio of 2:1; 2. Sludge hydrolyzate Preparation: The sludge after the ultrasonic treatment in step 1 was subjected to anaerobic hydrolysis for 2~3 days under the conditions of rotation speed of 180r / min and temperature of 35°C. During the hydrolysis process, the pH value was adjusted to 9.0 every 12h, and At nitrogen flow rate of 0.3m 3 Under the condition of / h, carry out a nitrogen blow-off every 12h to obtain the sludge hydrolyzate; 3. Add trace elements and other nutritional ...

specific Embodiment approach 2

[0018] Embodiment 2: This embodiment is different from Embodiment 1 in that: the pH value adjustment described in step 2 is carried out with 1 mol / L NaOH. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0019] Embodiment 3: This embodiment differs from Embodiments 1 to 2 in that the operating conditions of the high-pressure steam sterilization described in Step 3 are: 121° C., 121 KPa, sterilizing for 30 minutes. Others are the same as the specific embodiment 1 to 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com