Micronano manufacturing method of compound eye structure micro lens array

A technology of microlens array and compound eye, which is applied in the direction of lens, microstructure technology, microstructure device, etc., can solve the problems of inflexible control of structural parameters, low precision of compound eye structure on curved surface, expensive processing equipment, etc., and achieve low cost and easy Thermal deformation processing, the effect of a wide range of processing sizes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Step 1, selecting the hard material K9 glass for preparing the microlens array template;

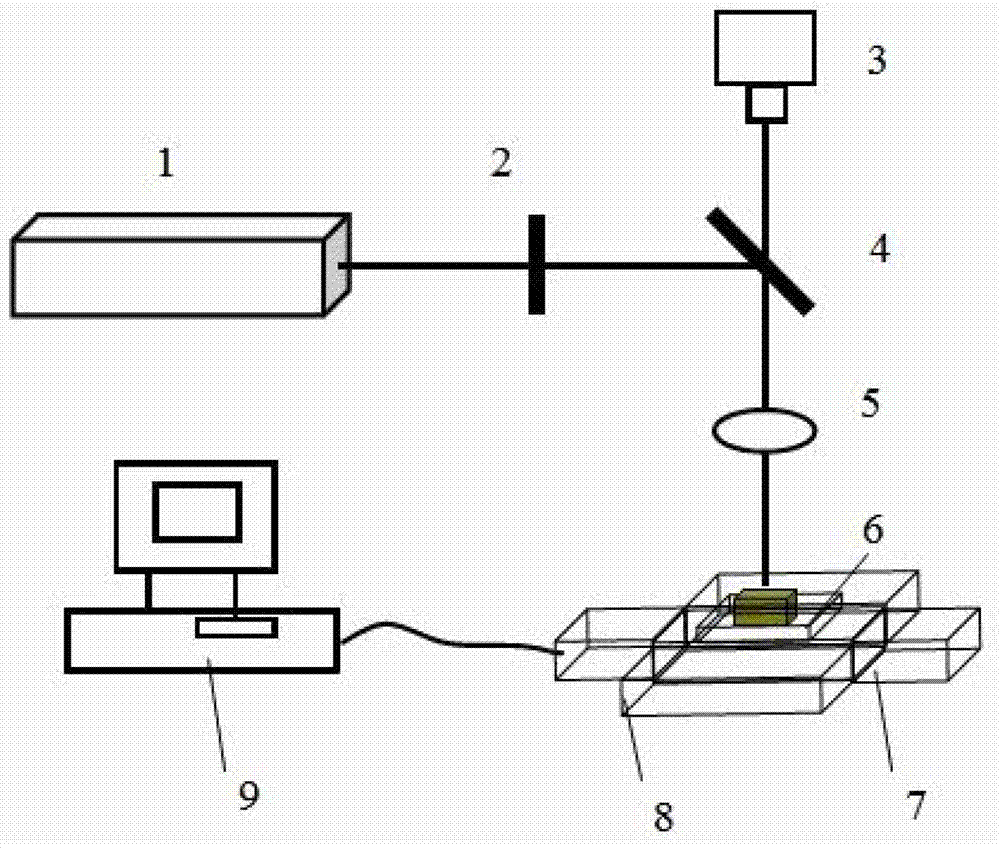

[0029] Step 2. Fix the hard material used to prepare the microlens array template on the three-dimensional precision translation stage, select an ultrashort pulse laser with a pulse width of 30 fs and a wavelength of 800 nm, and focus it on the hard material through an objective lens with a numerical aperture of 0.3 surface;

[0030] Step 3: The ultrashort pulse laser has a single pulse energy of 2.5uJ and a repetition rate of 1KHz, so that the ultrashort pulse laser acts on the surface of the material, and cooperates with the movement of the three-dimensional precision translation platform to ablate the required crater array;

[0031] Step 4: Place the hard material ablated into the crater array in a dilute solution of hydrofluoric acid with a volume concentration of 3% for corrosion, and the corrosion time is 120 minutes to prepare a microlens array template; supplemented by hea...

Embodiment 2

[0037] Step 1, selecting the hard material K9 glass for preparing the microlens array template;

[0038] Step 2. Fix the hard material used to prepare the microlens array template on the three-dimensional precision translation stage, select an ultrashort pulse laser with a pulse width of 50 fs and a wavelength of 400 nm, and focus it on the hard material through an objective lens with a numerical aperture value of 0.5 surface;

[0039] Step 3. Ultrashort pulse laser single pulse energy 5uJ, repetition frequency 1KHz, make ultrashort pulse laser act on the surface of the material, and cooperate with the movement of the three-dimensional precision translation stage to ablate the required crater array;

[0040] Step 4: Place the hard material ablated into the crater array in a diluent of hydrofluoric acid with a volume concentration of 5% for corrosion, and the corrosion time is 90 minutes to prepare a microlens array template; supplemented by heating in an ultrasonic oscillating...

Embodiment 3

[0044] Step 1, selecting the hard material K9 glass for preparing the microlens array template;

[0045]Step 2. Fix the hard material used to prepare the microlens array template on the three-dimensional precision translation stage, select an ultrashort pulse laser with a pulse width of 100 fs and a wavelength of 325 nm, and focus it on the hard material through an objective lens with a numerical aperture of 0.9 surface;

[0046] Step 3: The ultrashort pulse laser has a single pulse energy of 10uJ and a repetition rate of 1KHz, so that the ultrashort pulse laser acts on the surface of the material, and cooperates with the movement of the three-dimensional precision translation stage to ablate the required crater array;

[0047] Step 4. Put the hard material ablated into the crater array into a dilute hydrofluoric acid solution with a volume concentration of 10% for corrosion, and the corrosion time is 60 minutes to prepare a microlens array template; supplemented by heating in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com