Hollow honeycomb MnO2/C micro nanosphere and microrod preparation method

A micro-nano-sphere and honeycomb-shaped technology, which is applied in the field of electrochemical material preparation, can solve the problem of low film electrode area and achieve the effect of rich pore size, simple preparation process and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

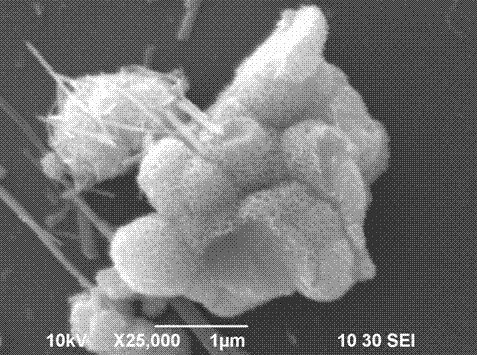

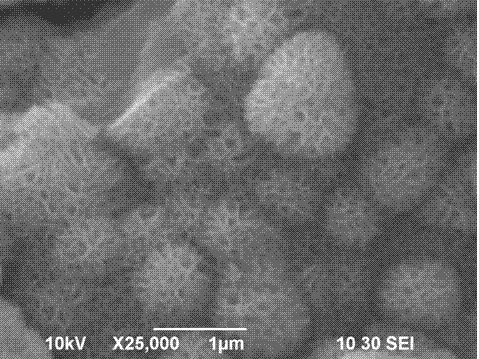

[0022] According to the ratio of the amount of substance 4:1 and MnO 2 Weigh 3% of the total amount of potassium permanganate, manganese chloride and graphite oxide, transfer the manganese chloride to a beaker filled with deionized water and stir it magnetically. After it is fully dissolved, add graphite oxide, and then slowly add potassium permanganate It is stirred and then transferred to a hydrothermal reactor with a filling rate of 40%. Then the hydrothermal reaction kettle was placed in an oven at 120 ℃ for hydrothermal reaction at a constant temperature for 3 h and then cooled to room temperature. The prepared product is washed and dried to obtain hollow honeycomb MnO 2 / C Micro and nano balls.

Embodiment 2

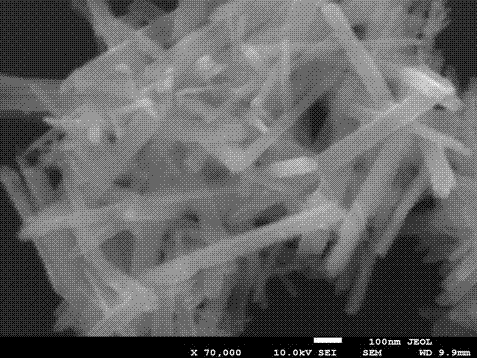

[0024] According to the ratio of the amount of substance 1:1 and MnO 2 Weigh 5% of the amount of potassium permanganate, manganese chloride and bamboo charcoal, transfer the manganese chloride to a beaker filled with deionized water and stir magnetically. After it is fully dissolved, add bamboo charcoal, then slowly add potassium permanganate and stir. , Then transferred to the hydrothermal reactor, the filling rate is 60%. Then the hydrothermal reaction kettle was placed in an oven at 150 ℃ for hydrothermal reaction for 6 h and then cooled to room temperature. The product is washed and dried to obtain bird's nest MnO 2 / C Micron rod material.

Embodiment 3

[0026] According to the ratio of the amount of the substance 0.25:1 and MnO 2 Weigh 9% of the total amount of potassium permanganate, manganese chloride and activated carbon, transfer the manganese chloride to a beaker filled with deionized water and stir magnetically. After it is fully dissolved, add activated carbon, then slowly add potassium permanganate and stir. , Then transferred to a hydrothermal reactor with a filling rate of 80%. Then the hydrothermal reaction kettle was placed in an oven at 150 ℃ for hydrothermal reaction for 6 h and then cooled to room temperature. The product is washed and dried to obtain bird's nest MnO 2 / C Micron rod material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com