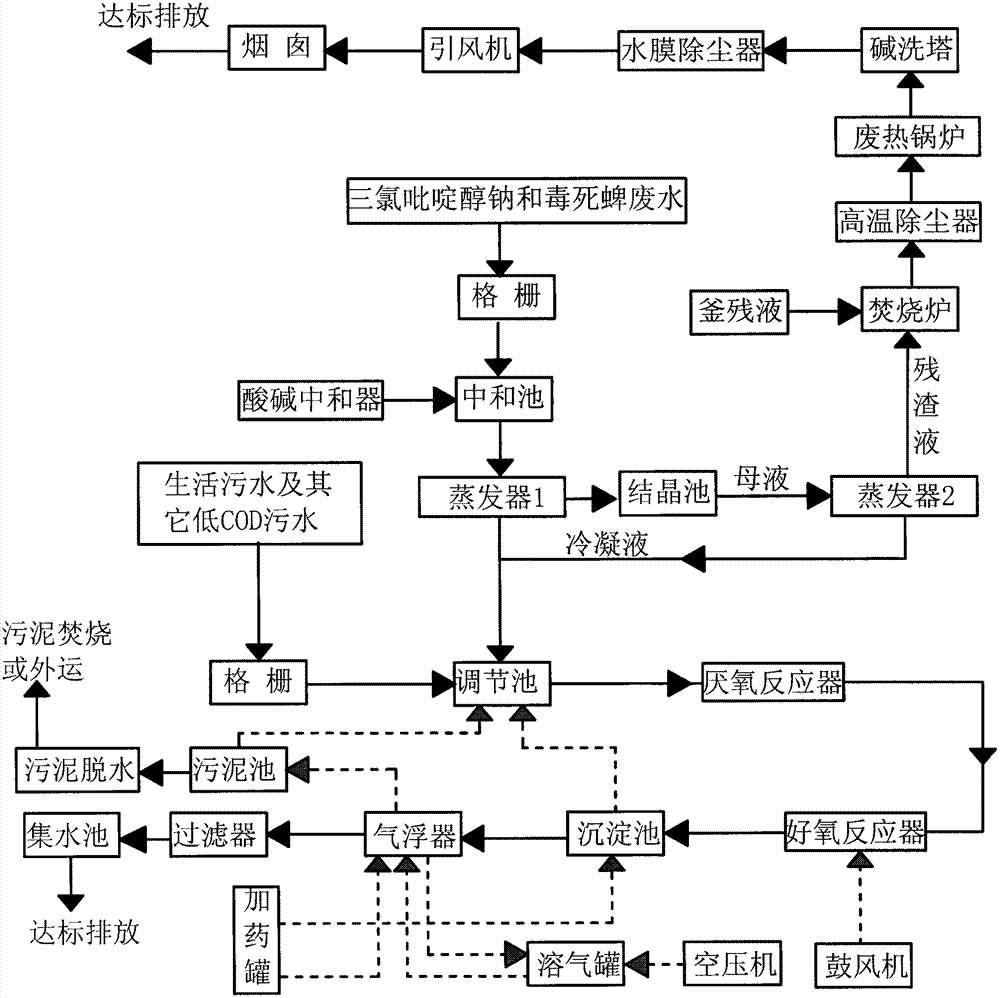

Treatment process for 3,5,6-Trichloropyridin-2-ol sodium and chlorpyrifos production wastewater

A technology for sodium clopyridinate and waste water production, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., and can solve the problems of waste of water resources, high microbial toxicity, and biodegradation Poor performance and other problems, to achieve the effect of reducing treatment costs, complete harmlessness, and small secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The comprehensive water volume of clopyridinate sodium and chlorpyrifos production wastewater to be treated is 7.5m 3 / h, the amount of domestic sewage and other low COD wastewater is 20m 3 / h. See Table 1 for the water quality of clopyridinate sodium and chlorpyrifos production wastewater, and Table 2 for the water quality of domestic sewage and other low-COD wastewater. After treatment, the effluent must meet the second-level standard in the "Integrated Wastewater Discharge Standard" GB8978-1996. The specific implementation of the discharge standard is shown in Table 3.

[0021] Table 1 The water quality of clopyridox sodium and chlorpyrifos production wastewater

[0022] CODcr (mg / L)

Sodium pyridyl alcohol content

Chlorobenzene content

pH

B / C

NaCl content

Cu+ content

60000

8.25%

4.67%

10

0.17

8.7%

0.3%

[0023] Table 2 Water quality of domestic sewage and other low COD wastewater ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com