Method for recycling urban sludge

A treatment method, the technology of urban sludge, applied in the field of resource treatment, can solve the problems of heat not being recycled, increased concentration of heavy metals in the soil, occupation of land resources, etc., to achieve the effect of promoting denitrification treatment, enhancing porosity, and operating costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

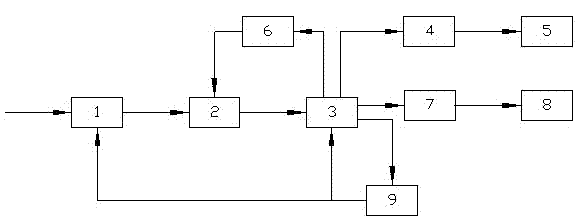

[0025] In order to better understand the inventive process, the present invention will be described in detail below through specific embodiments and in conjunction with the accompanying drawings.

[0026] Preparation of additives: the moisture content is less than 15% and has good pyrolysis performance, including but not limited to coal powder, fly ash and biomass powder.

[0027] Processing steps: see figure 1 After collecting or collecting dewatered sludge from urban sewage treatment plants with a moisture content of about 80%, it is continuously fed to the drying treatment system 1 for dehydration and drying. After drying, the moisture content of the sludge is reduced to between 40% and 60%. After crushing, it is mixed with admixture and granulated through the mixing molding system 2, so that the moisture content of the sludge granules is reduced to about 20%. Then it enters the medium-temperature carbonization system 3 to be pyrolyzed under the condition of isolating the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com