Method and device for realizing liquid crystal arbitrary orientation control through numerical control micromirror array photoetching

A digitally controlled micromirror and orientation control technology, which is applied in microlithography exposure equipment, photolithography exposure devices, optics, etc., can solve the problem of inability to achieve arbitrary polarization state control in different orientation regions, difficulty in preparing complex patterns, and graphic resolution. Limitation and other issues, to achieve the effect of enriching the tuning control dimension, improving the tuning control dimension, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

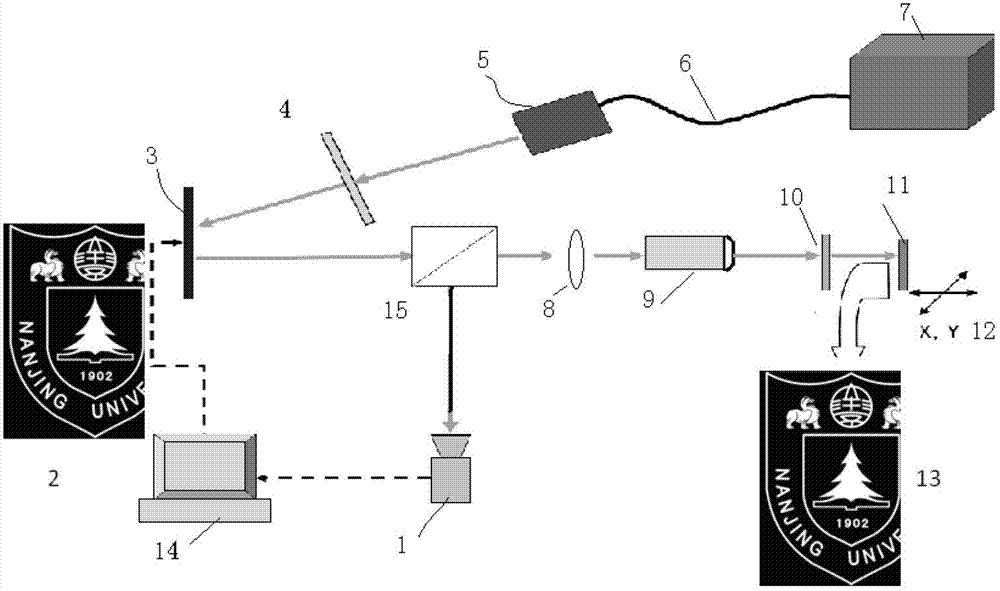

[0040] A DMD-based lithography system was used to realize the fabrication of polarization controller arrays.

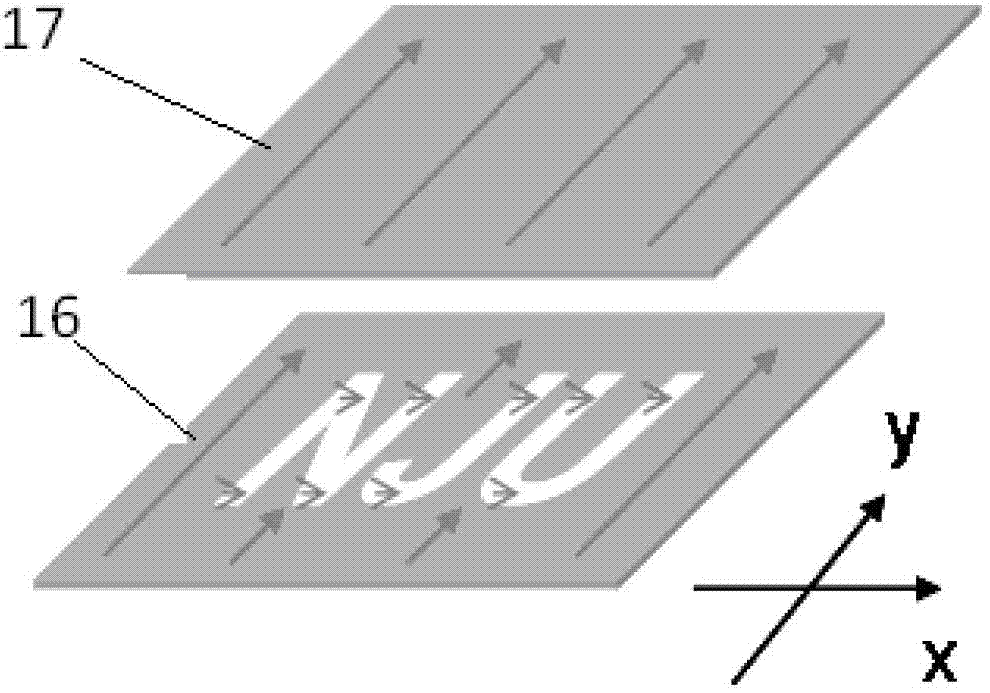

[0041] A DMD photolithography system and steps similar to those in Example 1 were used, a 1000W ultraviolet light source was used, and a cinnamate-based photoalignment agent was used. When exposing the substrate 2, such as Figure 5 As shown, let the DMD output the word "NJU" first, and adjust the direction of the polarizer so that the orientation direction of the exposure area is perpendicular to the orientation direction of the substrate 1 . Then change the output graphics of DMD, exposure in turn Figure 5 For each circular area in , different polarizer orientations are selected for each exposure. After the exposure, according to the step (4) of Example 1, two substrates were formed into a liquid crystal cell. In this way, in different regions of the liquid crystal cell, the liquid crystal molecules will have different twist angles. Here, the letter "NJU" and t...

Embodiment 3

[0043] The phase retarder array was fabricated using a DMD-based photolithography system.

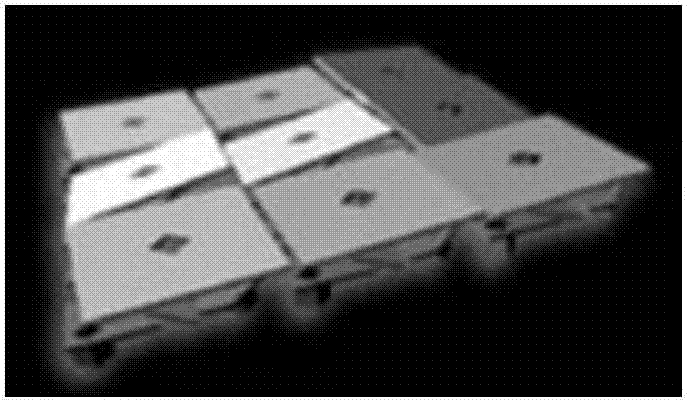

[0044] A DMD photolithography system and steps similar to those in Examples 1 and 2 were used, a 1000W ultraviolet light source was used, and a polyimide-based photoalignment agent was used. Firstly, two substrates oriented in the same direction are made into a liquid crystal cell. Then use the DMD photolithography system to expose step by step. First, let the DMD output the word "NJU" in the pattern, and adjust the direction of the polarizer so that the orientation direction of the exposure area is perpendicular to the orientation direction of the two substrates. Then change the output graphics of DMD, exposure in turn Figure 6 Each numbered field in each exposure rotates a different polarizer orientation. As shown by the numbers in the figure, the included angles between the liquid crystal orientation and the preset orientation are 90°, 80°, 70°, 60°...10° in sequence. After the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com