Porous submicron sphere, porous film electrode and preparation method and application in dye sensitized solar cells thereof

A porous film and sub-micron technology, which is applied in the interdisciplinary field of chemistry and nanomaterials, can solve the problems of large specific surface area, high light scattering electron transmission path, affecting the photoelectric conversion efficiency of the battery, limiting the performance of the device, etc., and achieving low light transmission. Overrate, improve photoelectric conversion efficiency, improve the effect of photocurrent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

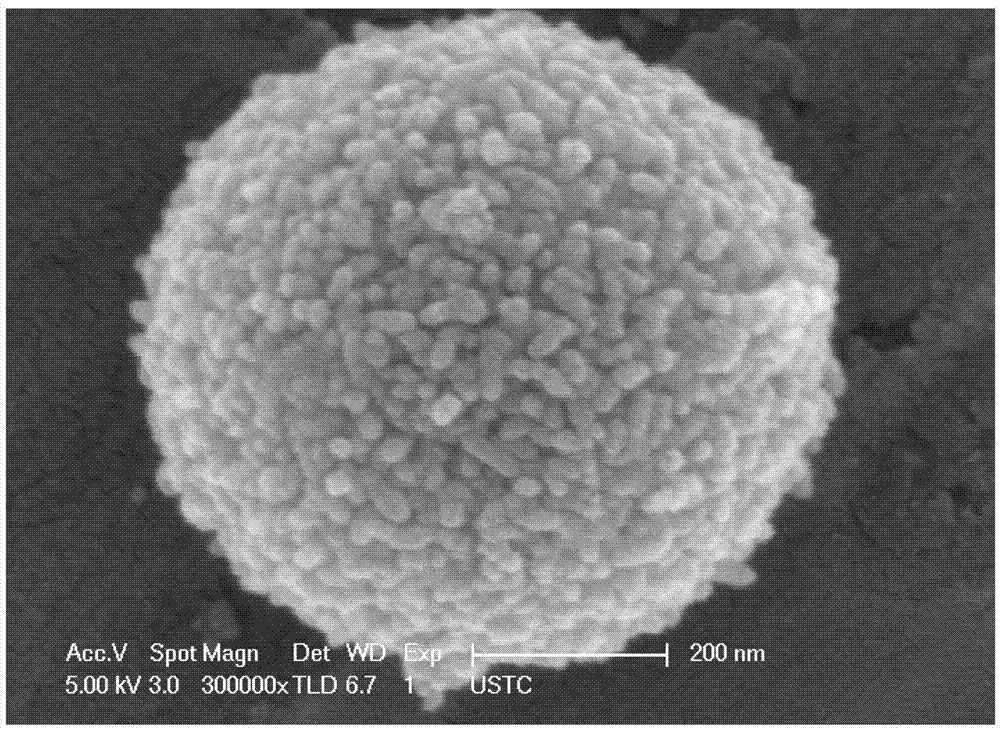

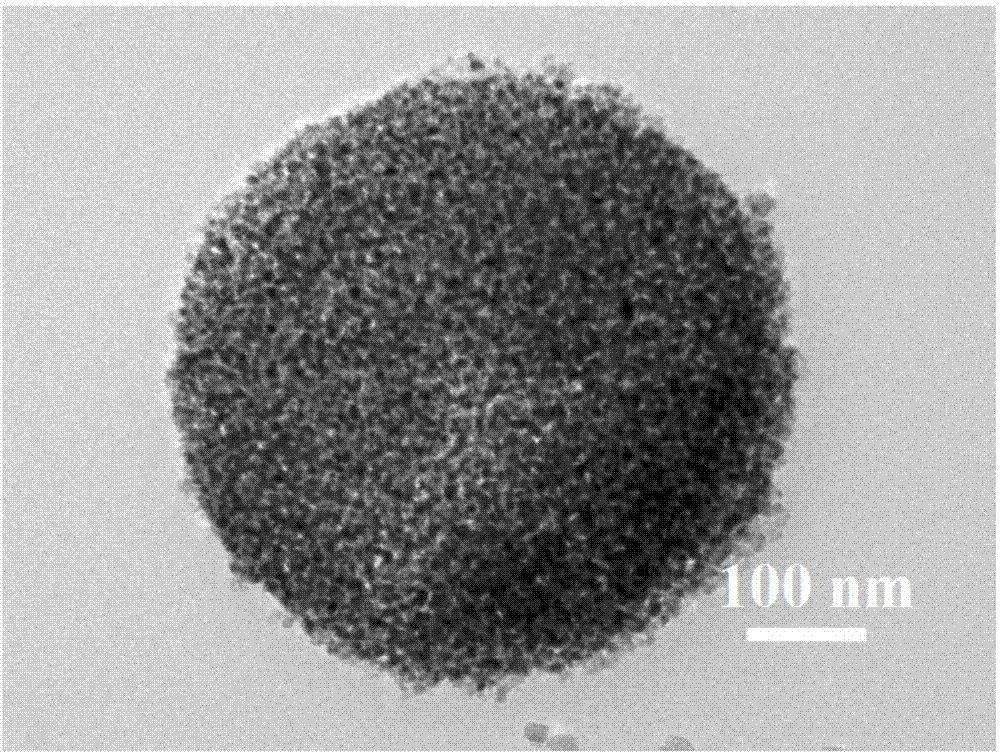

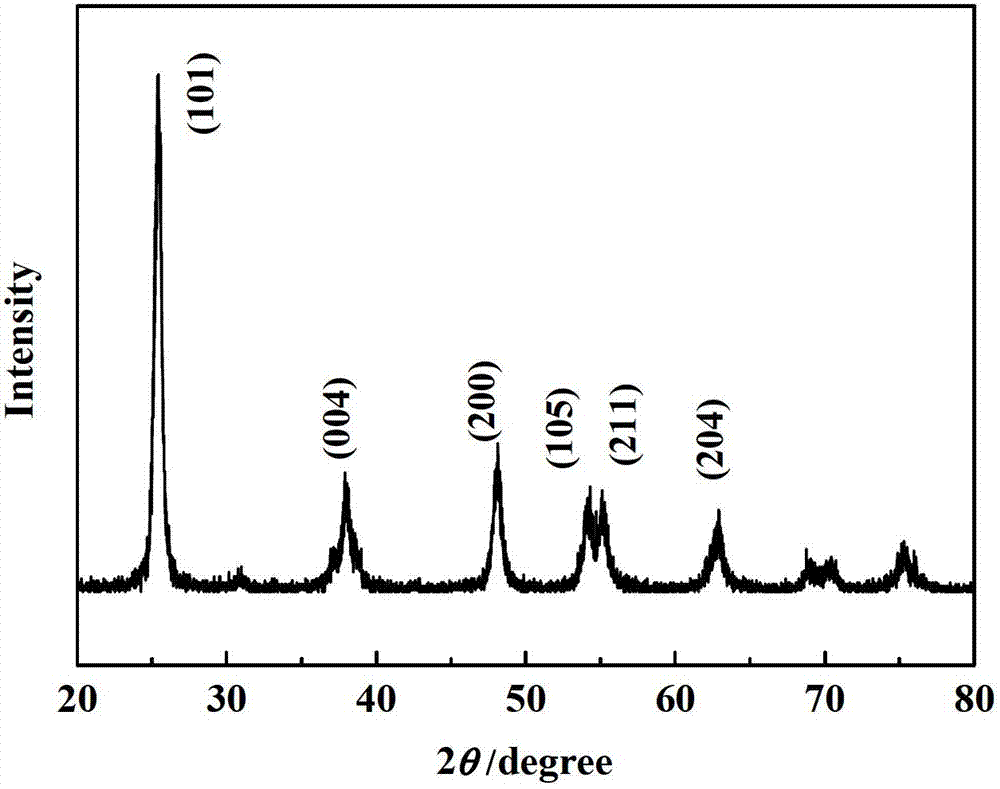

[0040] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , at room temperature and under the protection of a nitrogen atmosphere, 2ml of 0.1mol / L KCl solution and 2ml of deionized water were added to 250ml of absolute ethanol, stirred at 500rpm for 10 minutes, and then 5ml of tetraisopropyl titanate was added dropwise to the In the mixed solution, the reaction was continued for 6 hours with constant stirring, and a white precipitate was produced, which was collected by filtration. Then wash with deionized water and alcohol repeatedly 5 times each, then disperse the white solid into a mixed solution of 10ml ethanol and 30ml water containing 3ml ammonia water, and keep stirring until it becomes a sol. The sol was then transferred into an autoclave and heat-treated at 160°C for 25 hours; water and ammonia were removed by washing and vacuum rotary evaporation, and a porous submicron spherical powder with a wide diameter distribution composed of titanium d...

Embodiment 2

[0043] At room temperature and under the protection of a nitrogen atmosphere, 2ml of 0.1mol / L KCl solution and 2ml of deionized water were added to 250ml of absolute ethanol, stirred at 500rpm for 10 minutes, and then 5ml of tetraisopropyl titanate was added dropwise to the In the mixed solution, the reaction was continued for 6 hours with constant stirring. A white precipitate produced which was collected by suction filtration. Then wash with deionized water and alcohol repeatedly 5 times each, and then disperse the white solid into HNO with a pH value of 0.1 3 In the aqueous solution, keep stirring until it becomes a sol. The sol was then transferred into an autoclave and heat-treated at 180°C for 30 hours. Removal of water and HNO by washing and vacuum rotary evaporation 3 , uniformly disperse the collected titanium dioxide porous submicron spheres with wide diameter distribution in absolute alcohol, to be applied to other fields.

[0044] 5 g graded TiO 2 The porous s...

Embodiment 3

[0046] At room temperature and under the protection of a nitrogen atmosphere, 2ml of 0.1mol / L KCl solution and 2ml of deionized water were added to 250ml of absolute ethanol, stirred at 500rpm for 10 minutes, and then 5ml of tetraisopropyl titanate was added dropwise to the In the mixed solution, the reaction was continued for 6 hours with constant stirring. A white precipitate produced which was collected by suction filtration. Then wash with deionized water and alcohol repeatedly 5 times each, and then disperse the white solid into 0.1mol / L HNO 3 In the aqueous solution, keep stirring until it becomes a sol. The sol was then transferred into an autoclave and heat-treated at 200° C. for 15 hours. Removal of water and HNO by washing and vacuum rotary evaporation 3 , after drying and grinding, a porous submicron spherical powder with a wide diameter distribution composed of titanium dioxide nanoparticles was collected.

[0047] 5 g graded TiO 2 The porous submicron spheric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com