Reinforcing agent for papermaking and preparation method thereof

A technology of reinforcing agent and monomer, which is used in the field of synthetic polymer reinforcing materials to achieve the effect of stable reaction and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

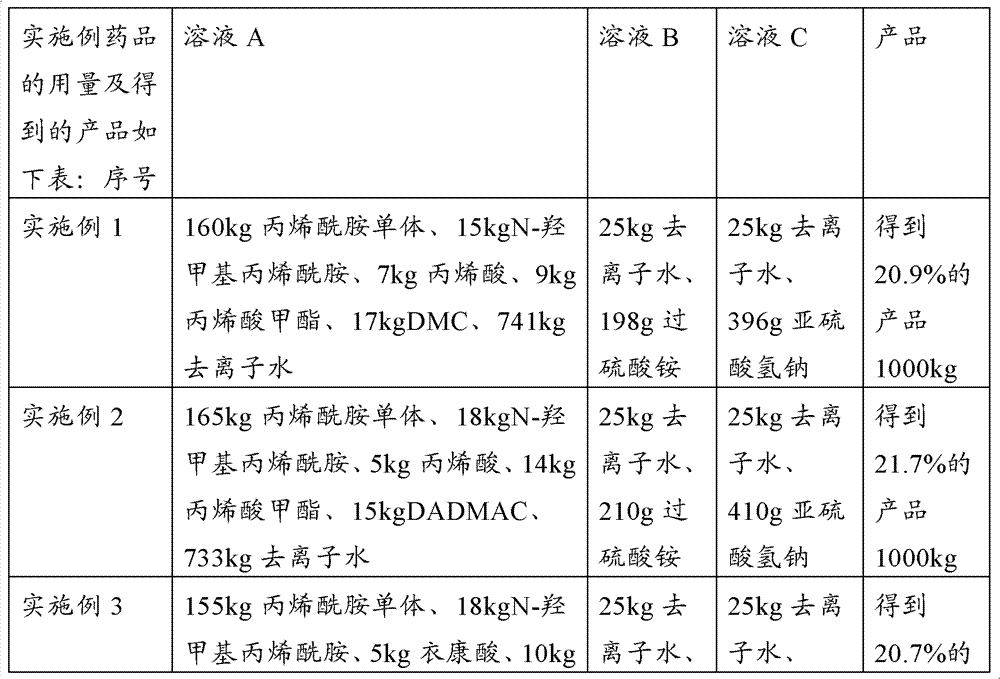

Examples

experiment example 1

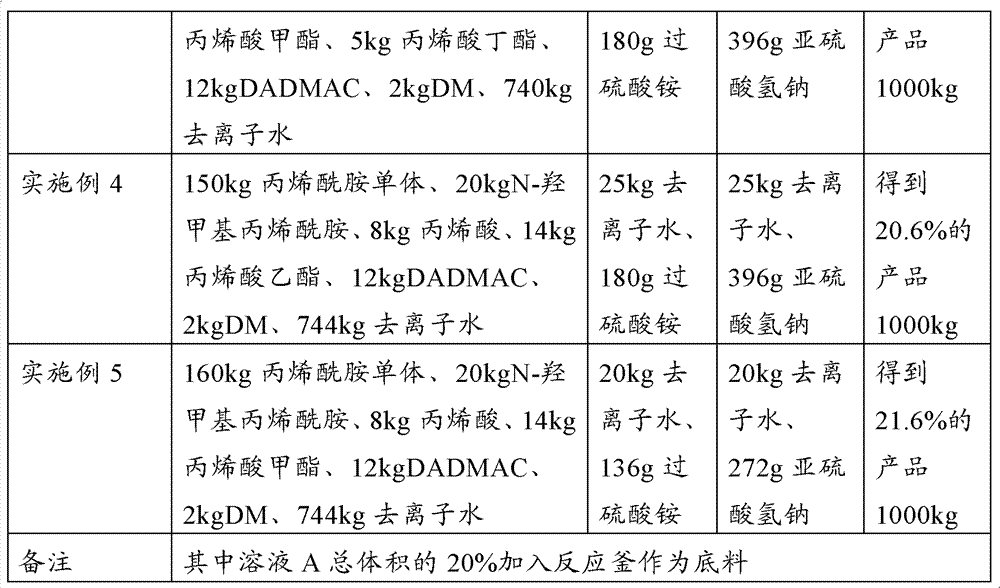

[0030] The application effect was evaluated in a paper mill in Shandong, and compared with RS-218 enhanced starch (enhancer 1#).

[0031] Dilute the strengthening agent formulated in Examples 1 to 5 by 25 times with water on-line, and add it in an amount of 10kg / t paper, add it to the inlet of the pulp pump at the outlet of the stock tank, and enter the paper machine flow delivery system.

[0032] According to GB / T 13024-2003 "Container Board", the folding endurance, bursting strength and ring compressive strength of the cardboard are measured, and the quantitative value of the cardboard during the test machine is 200g / m 2 . The results are shown in Table 1.

[0033] Table 1

[0034]

[0035]

[0036] As can be seen from the results in Table 1: using the reinforcing agent prepared in Examples 1 to 7 of the present invention, compared with the blank sample, the three important indexes of the boxboard have been greatly improved, and compared with the RS-218 reinforced st...

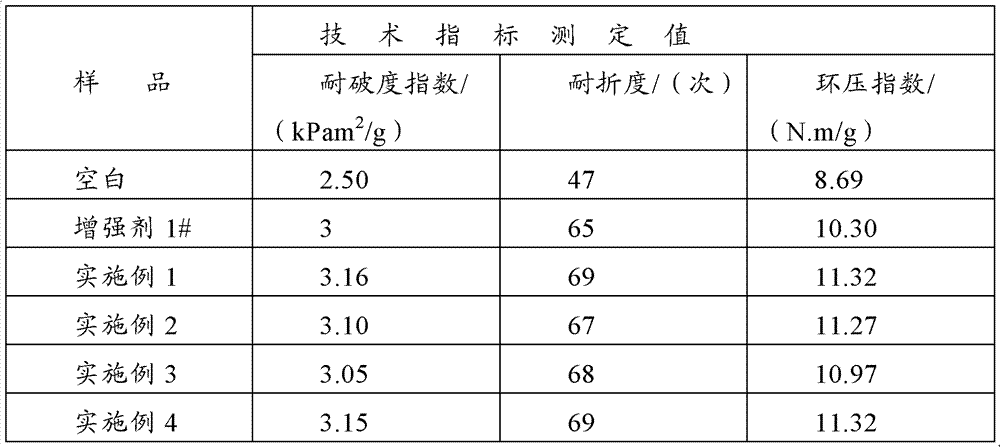

experiment example 2

[0038] The application effect was evaluated in a paper mill in Shandong, and compared with the strengthening agent model KJP-15 (manufactured by Yonggang Weifang Technology Co., Ltd., referred to as strengthening agent 2# here).

[0039] Dilute the strengthening agent formulated in Examples 1 to 5 by 25 times with water online, and add it to the outlet of the pulp tank and the inlet of the pulp pump in an amount of 10 kg / t paper, and then enter the paper machine flow delivery system.

[0040] According to GB / T 13023-2008 "Corrugated Core (Original) Paper", the ring crush strength, flat crush index and longitudinal fracture length of the paper are measured, and the quantitative value during the test machine is 110g / m 2 . The results are shown in Table 2.

[0041] Table 2

[0042]

[0043] As can be seen from the results in Table 2: using the strengthening agent prepared in Examples 1 to 5 of the present invention, compared with the blank sample, the three important indicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com