RDL (radiological defense laboratory) technology-compatible inductive component and manufacture method

A technology of inductance components and inductances, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve problems such as unfavorable industrial production, polluting devices, complicated processes, etc. The effect of reducing packaging costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to fully demonstrate the advantages and positive effects of the present invention, the substantive features and remarkable progress of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

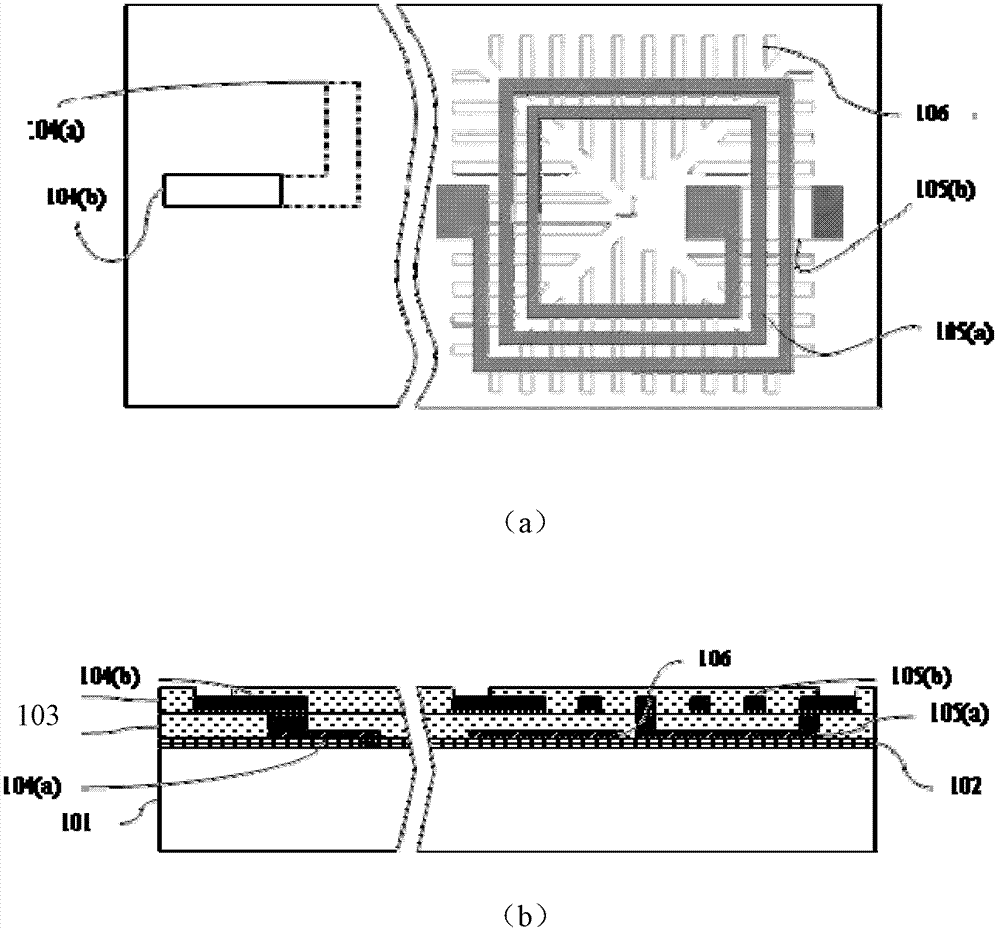

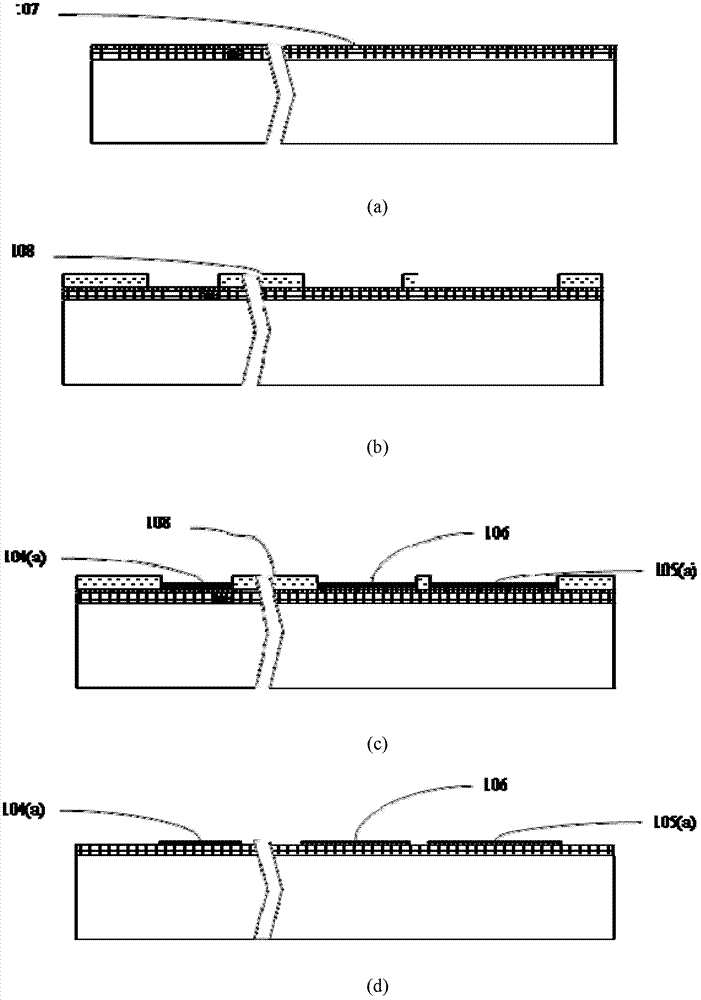

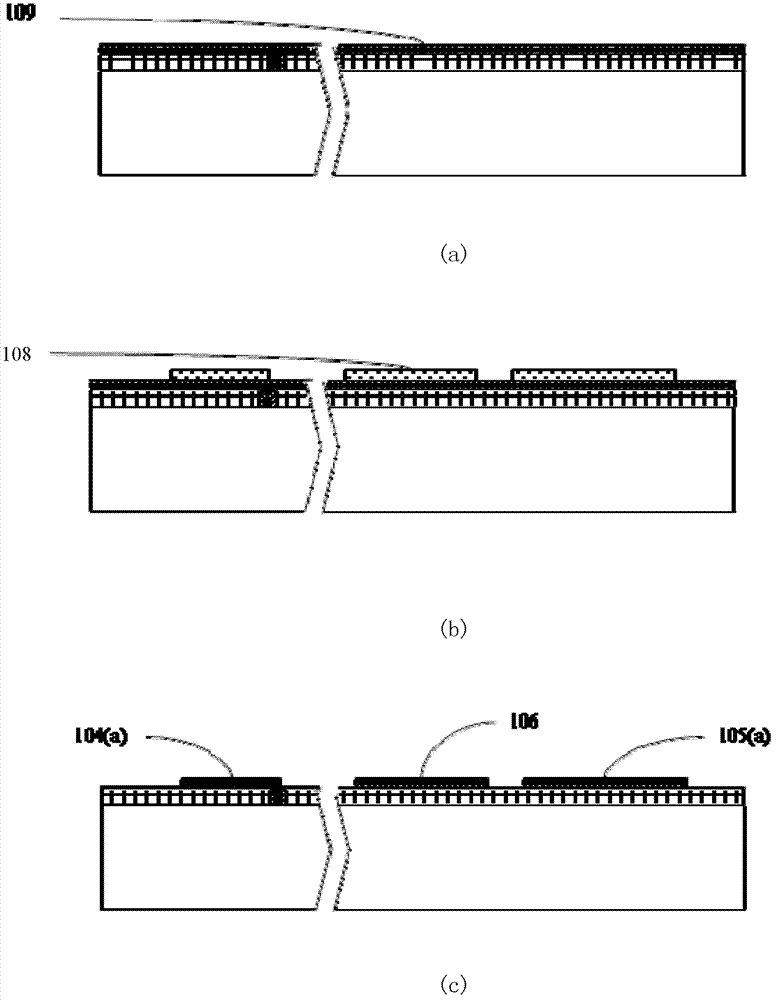

[0060] like figure 1 As shown, 106 is a ray-shaped metal shielding layer pattern, each of which has a width of 10 μm, and the shortest distance between two adjacent rays is 30 μm, and each ray is perpendicular to the corresponding side of the square spiral inductor directly above, effectively weakening the Eddy current. The first redistribution metal transmission layer 104 (a), the inductance bridge line 105 (a) and the radial metal shielding layer 106 are simultaneously deposited on the substrate 101 by a thin film process, and the substrate 101 can be a standard silicon chip or a chip embedded therein Ordinary silicon wafers. Passivation barrier layer 102 may be SiO 2 , a low dielectric constant medium or a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com