Application treatment method of chromium-containing waste acid sludge in stainless steel factory

A technology of application treatment and stainless steel, applied in the direction of chromium oxide/hydrate, etc., to achieve the effect of stable performance, high recovery rate of chromium, and pure color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

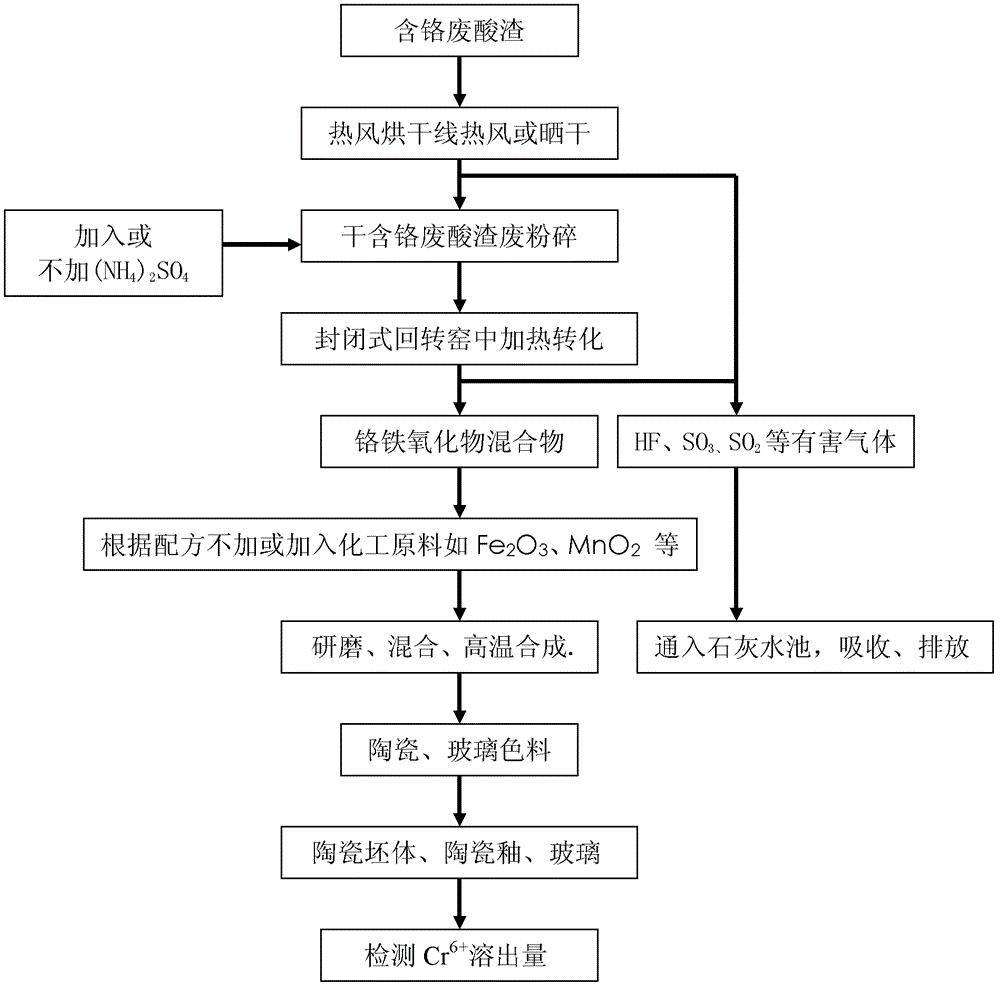

Method used

Image

Examples

preparation example Construction

[0054] 3) Preparation of colorants:

[0055] The ferrochromium oxide mixture is directly used as ceramic and glass pigments;

[0056] Or the chromium-iron oxide mixture is used as a raw material for synthesizing ceramic pigments and glass pigments.

[0057] The preparation of color materials adopts Fe-Cr, Fe-Cr-Co, Fe-Cr-Co-Mn series color materials, and the specific method is:

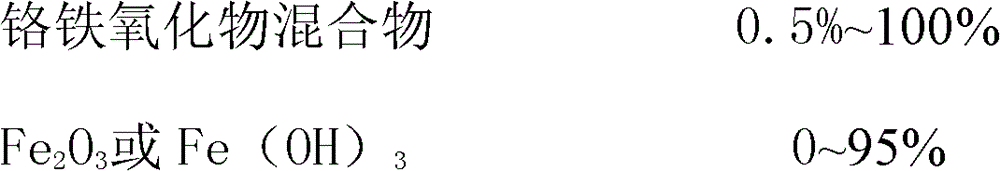

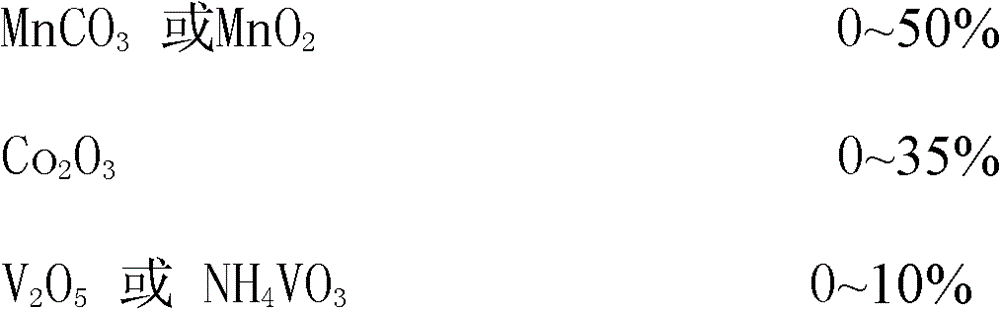

[0058] Weigh the following raw materials by mass percentage:

[0059]

[0060] If the above percentage is 0, it means that the ferrochromium oxide mixture is directly used as a colorant, and is not used as a raw material for synthetic colorant.

[0061] The above-mentioned materials are mixed evenly according to a certain ratio, ground to 40 mesh to 600 mesh and fully mixed to make batch materials. Then the mixture is synthesized in a high-temperature furnace, the synthesis temperature is 600°C-1300°C, and the holding time is 0-168 hours.

Embodiment 1

[0062] Embodiment 1: ceramic green body black pigment

[0063] 1.1 Drying treatment of chromium-containing waste acid residue

[0064] The chromium-containing waste acid slag produced during the stainless steel pickling process with a water content of 25% is dried on a hot air drying line at 80° C. to remove the attached water and part of the crystallization water of the chromium-containing waste acid slag. Grind to about 50 mesh with a hammer mill.

[0065] 1.2 Preparation of ferrochromium oxide mixture

[0066] Combine the dried and pulverized chromium-containing waste acid slag with (NH 4 ) 2 SO 4 Mix evenly according to the ratio of 1:0.4, put it into a closed rotary kiln and heat and react to obtain a mixture of ferrochrome oxides. The heating temperature of the rotary kiln is 150 ° C, the atmosphere is an oxidizing atmosphere, and it is pulverized to about 250 mesh with a pulverizer. Cr 6+ .

[0067] 1.3 Preparation of black pigment for ceramic body

[0068] Weig...

Embodiment 2

[0071] Embodiment 2: ceramic green body brown pigment

[0072] 2.1 Drying treatment of chromium-containing waste acid residue

[0073] The chromium-containing waste acid slag generated during the stainless steel pickling process with a water content of 25% is dried through a hot air drying line at 200°C to remove the attached water and part of the crystallization water of the chromium-containing waste acid slag. Grind to about 50 mesh with a hammer mill.

[0074] 2.2 Preparation of ferrochromium oxide mixture

[0075] Combine the dried and pulverized chromium-containing waste acid slag with (NH 4 ) 2 SO 4 Mix evenly according to the ratio of 1:0.4; put it into a closed rotary kiln and heat and react to obtain a mixture of ferrochrome oxides. The heating temperature of the rotary kiln is 1380 ° C, and the atmosphere is an oxidizing atmosphere. Cr 6+ .

[0076] 2.3 Preparation of brown pigment for ceramic body

[0077] Weigh the crushed ferrochrome oxide mixture 15%, Fe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com