High-activity composite cellulase and preparation thereof, and application method for same in enzymatic saccharification of wood fiber

A technology of compound cellulase and application method, which is applied in the field of high-activity compound cellulase and its preparation and application in lignocellulosic enzymatic saccharification, can solve the problems of reducing ethanol yield, affecting the efficiency of enzymatic saccharification, fiber two Sugar accumulation and other problems, to achieve the effect of low cost, low cost and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

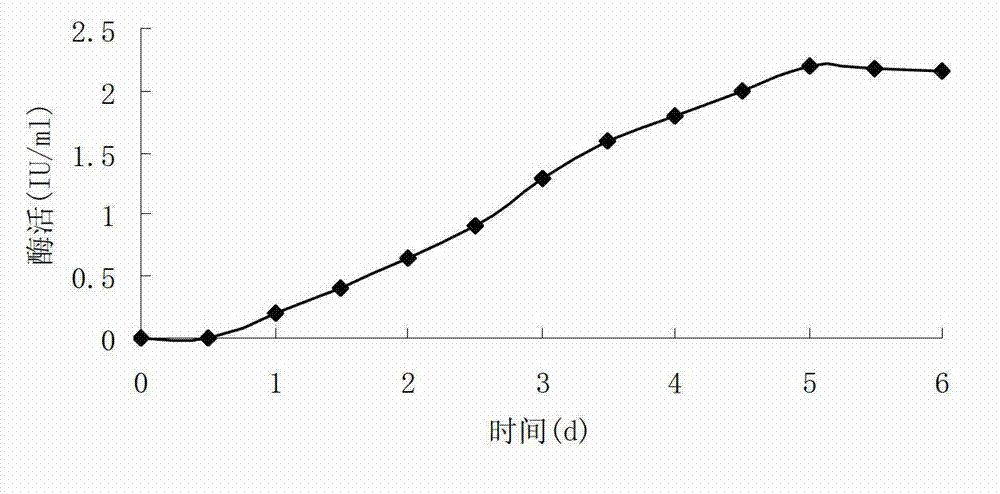

[0032] Pick a ring of spores from the laboratory-preserved Penicillium javanese ZN-205 potato solid plate medium and inoculate it into a 250ml shaker flask filled with 50ml of seed medium, and culture it on a shaker at 28°C and 200rpm for 2.5-3 days as inoculation things. According to the inoculum amount of 5% (v / v), the above culture was inoculated into a 250ml shake flask containing 50ml of enzyme-producing medium, and cultured at 28°C and 200rpm for 5 days. Centrifuge at 4000rpm for 10min, and the supernatant is the crude enzyme solution. Its β-glucosidase activity was determined to be 1.521IU / ml.

[0033]Penicillium javanica ZN-205 seed medium: glucose 20g / L, peptone 1g / L, Mandels nutrient salt concentrate 100ml / L, Mandels trace element concentrate 1ml / L, 1M citric acid buffer 50ml / L, add water to 1L.

[0034] Penicillium javanica ZN-205 enzyme production medium: microcrystalline cellulose 25g / L, peptone 5g / L, KH 2 PO 4 2g / L, CaCl 2 2H 2 O 0.4g / L, MgSO 4 ·7H 2 O ...

Embodiment 2

[0043] The present invention continues to optimize the β-glucosidase production process of Penicillium javanica ZN-205 in Example 1 by using a single factor experimental design, as follows.

[0044] Single factor test of enzyme production medium: keep other components in the enzyme production liquid medium unchanged, change the four factors of carbon source, nitrogen source, pH value and surfactant (Tween-80) respectively (Table 1), screen The single factor affecting the optimal enzyme-producing medium of Penicillium javanica ZN-205 for producing β-glucosidase was found. The order of the influence of various factors on the activity of β-glucosidase was: carbon source > nitrogen source > surfactant > initial pH. The optimal combination was obtained from the test results (Table 2): the initial pH was 6.0, the mass concentration of nitrogen source was 0.75%, the mass concentration of carbon source was 2.5%, and the addition of Tween-80 was 0.05wt%.

[0045] Table 1 Orthogonal ex...

Embodiment 3

[0061] The preparation method of composite cellulase of the present invention is specifically as follows:

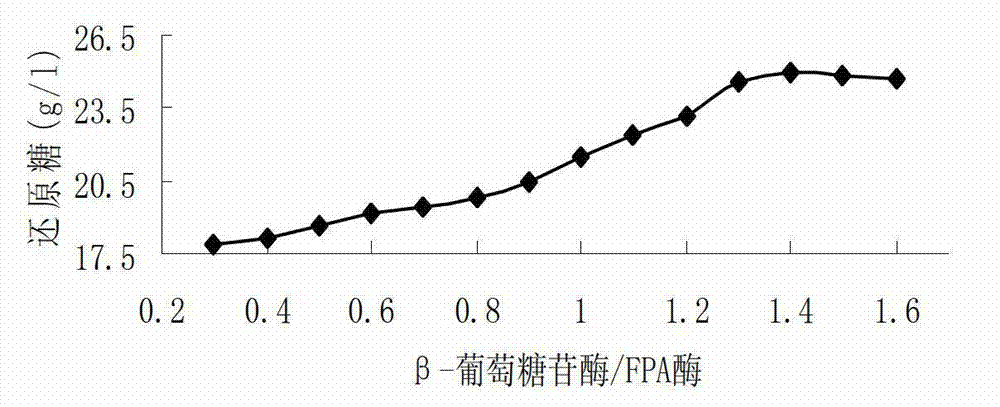

[0062] Using self-selected Penicillium javanica ZN-205 to carry out shake-flask fermentation under the optimal conditions of the above-mentioned Example 2 to produce β-glucosidase, and purchased Trichoderma reesei Ru-C30 (ATCC 56765) to prepare cellulose Enzyme (Ref. 1 for its method). The method for measuring β-glucosidase activity adopts the method provided by the present invention, and the method for measuring filter paper enzyme activity (FPA) adopts the method recommended by Ghose (see reference 2). The filter paper enzyme activity (FPA) of Trichoderma reesei Ru-C30 crude enzyme solution was 6.212IU / ml, and the β-glucosidase activity was 1.352IU / ml; the ultrafiltration concentrator of Tianjin Motianmo Technology Co., Ltd. (UOF 48) After concentration for 20 minutes, the filter paper enzyme activity (FPA) of the enzyme liquid is 46.912IU / ml, the β-glucosidase activi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com