Molten metal antioxidant biological reducing agent and preparation method thereof

A molten metal, anti-oxidation technology, applied in the direction of metal material coating process, coating, hot-dip plating process, etc., can solve the problems of poor quality of molten metal, corrosiveness of machines, carcinogens, etc., to reduce metal tension, The machine is non-corrosive and non-carcinogenic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

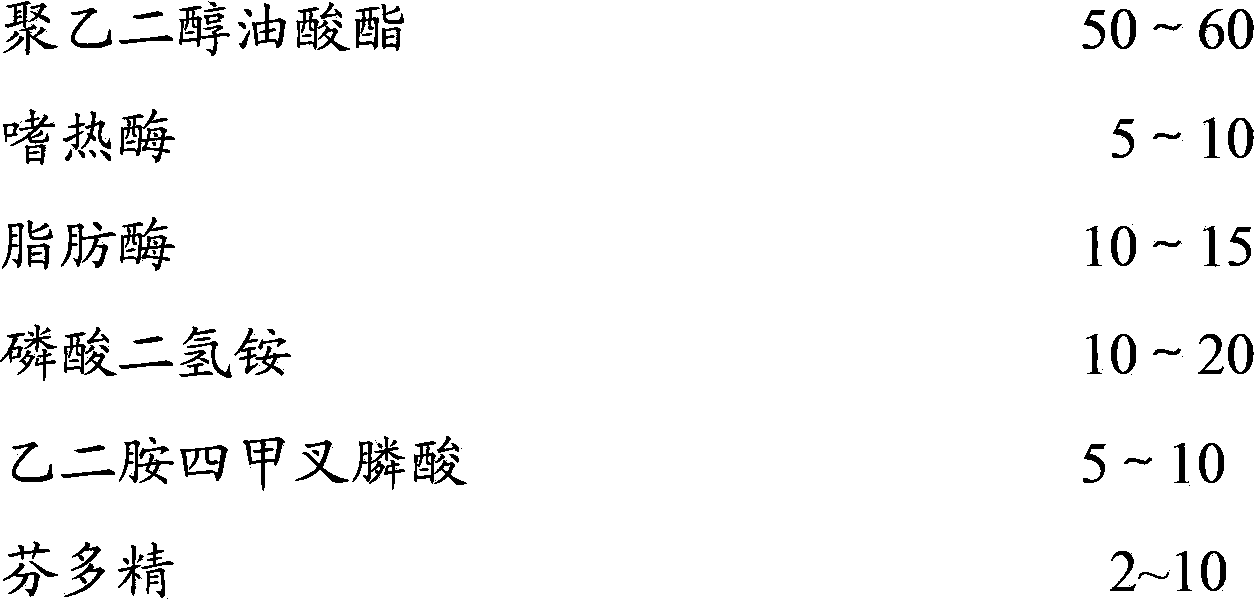

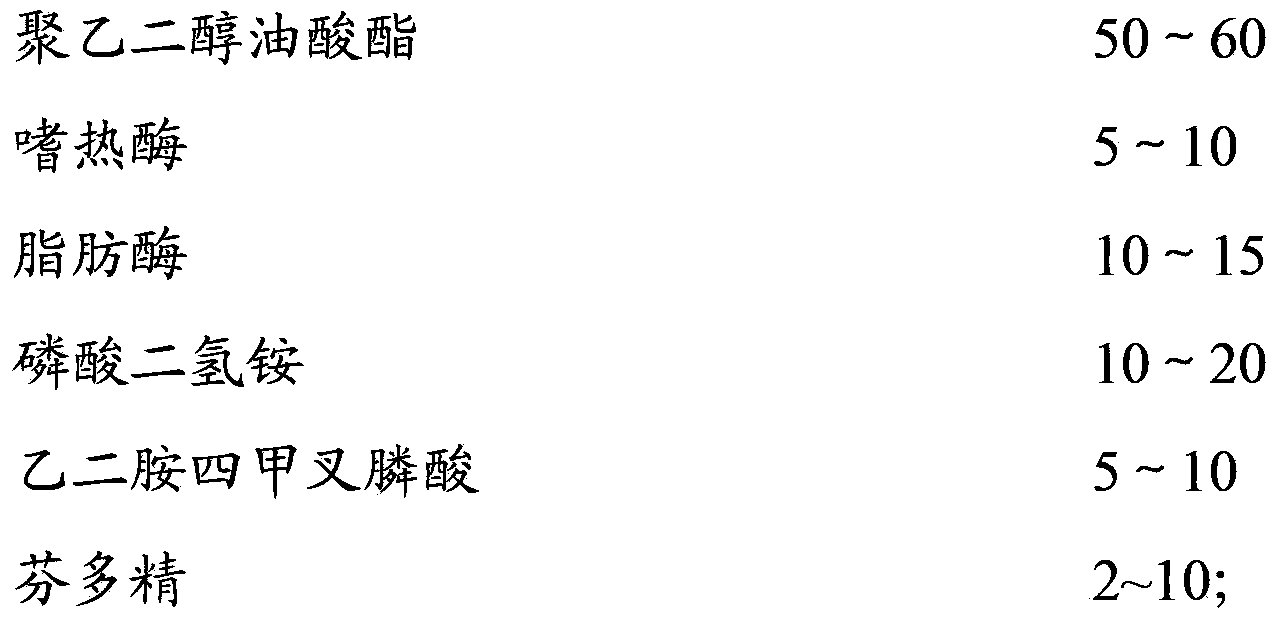

[0014] A molten metal antioxidant bioreductant, comprising the following substances calculated according to the ratio of parts by weight: 50 kg of polyethylene glycol oleate, 5 kg of thermophilic enzyme, 10 kg of lipase, 20 kg of ammonium dihydrogen phosphate, 10 kg of diamine tetramethylene phosphonic acid, 5 kg of phytondor.

[0015] Preparation:

[0016] First put the amount of polyethylene glycol oleate into the reactor and heat it to 60°C, then put the amount of thermophilic enzyme into the reactor and stir slowly; after the mixed substances in the reactor are completely dissolved, Maintain the temperature at 35°C and slowly add the amount of lipase; continue to maintain the temperature at 60°C and add ammonium dihydrogen phosphate, cool to normal temperature after the mixture is completely dissolved, and finally add the amount of ethylenediamine tetramethylene phosphonic acid and Phentermine is stirred slowly at the same time, and the molten metal antioxidant bioreducta...

Embodiment 2

[0018] A molten metal antioxidant bioreductant, comprising the following substances calculated according to the ratio of parts by weight: 60 kg of polyethylene glycol oleate, 5 kg of thermophilic enzyme, 10 kg of lipase, 10 kg of ammonium dihydrogen phosphate, 5 kg of diamine tetramethylene phosphonic acid, 10 kg of phytondor.

[0019] Preparation:

[0020] First put the amount of polyethylene glycol oleate into the reactor and heat it to 65°C, then put the amount of thermophilic enzyme into the reactor and stir slowly; after the mixed substances in the reactor are completely dissolved, Maintain the temperature at 30°C and slowly add the amount of lipase; continue to maintain the temperature at 70°C and add ammonium dihydrogen phosphate, cool to normal temperature after the mixture is completely dissolved, and finally add the amount of ethylenediamine tetramethylene phosphonic acid and Phentermine is stirred slowly at the same time, and the molten metal antioxidant bioreducta...

Embodiment 3

[0022] A molten metal antioxidant bioreductant, comprising the following substances calculated according to the ratio of parts by weight: 55 kg of polyethylene glycol oleate, 10 kg of thermophilic enzyme, 12 kg of lipase, 16 kg of ammonium dihydrogen phosphate, 5 kg of diamine tetramethylene phosphonic acid, 2 kg of phytondor.

[0023] Preparation:

[0024] First put the amount of polyethylene glycol oleate into the reactor and heat it to 68°C, then put the amount of thermophilic enzyme into the reactor and stir slowly; after the mixed substances in the reactor are completely dissolved, Maintain the temperature at 32°C and slowly add the amount of lipase; continue to maintain the temperature at 65°C and add ammonium dihydrogen phosphate, cool to normal temperature after the mixture is completely dissolved, and finally add the amount of ethylenediamine tetramethylene phosphonic acid and Phentermine is stirred slowly at the same time, and the molten metal antioxidant bioreducta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com