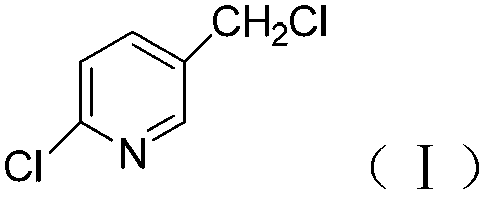

Method for continuous preparation of 2-chloro-5-chloromethylpyridine in microchannel

The technology of chloromethylpyridine and picoline, which is applied in the field of preparation of 2-chloro-5-chloromethylpyridine, can solve the problems of high raw material price, long reaction steps, unsatisfactory cyclization reaction yield and the like, To achieve the effect of simple preparation, short production cycle, continuous stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

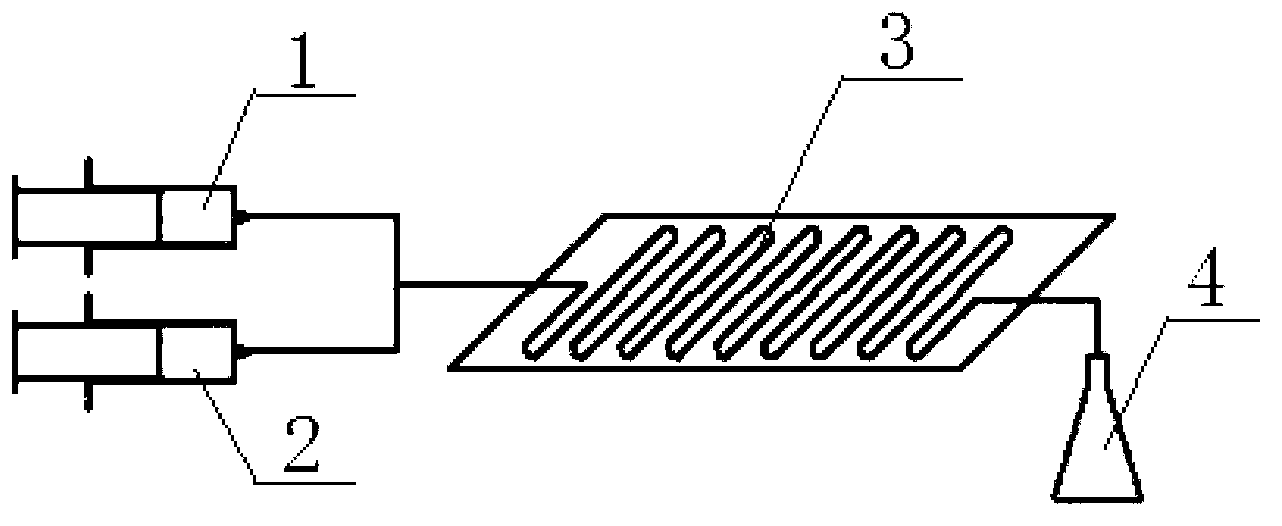

[0025] Example 1 (optimal process conditions)

[0026] Mix 6.38g (0.05mol) 2-chloro-5-methylpyridine and 0.1g (0.0006mol) azobisisobutyronitrile (AIBN) in 12.5ml chlorobenzene to prepare 2-chloro-5-methyl The final concentration of pyridine is 0.003mol / ml mixed solution, as sample solution A; measure sulfuryl chloride SO 2 Cl 2 3.38g (0.025mol), dissolved in 16ml of chlorobenzene to form a mixed solution of sulfonyl chloride with a final concentration of 0.0015mol / ml, as sample B. The calibrated syringe pumps (model LSP01-1A, manufacturer: Baoding Lange Constant Flow Pump Co., Ltd.) of sample solution A and sample solution B are sent to the microchannel reactor with a total flow rate of 2.0m / min. Before raising the temperature of the microchannel reactor to 110℃, the residence time of sample A and sample B in the microchannel reactor (a polytetrafluoroethylene tube with inner diameter D=0.6mm and length L=2m) is 60s, and collect The effluent from the outlet of the microchannel r...

Embodiment 2

[0030] Sample solution A and sample solution B are the same as in Example 1; sample solution A and sample solution B are injected into the microchannel reactor at a certain flow rate for reaction. The total flow rate, reaction temperature, residence time, inner diameter and other process parameters are shown in Table 2. Collect the effluent reaction solution to obtain the reaction solution of 2-chloro-5-chloromethylpyridine. The single-pass yield is over 30~68% by gas chromatography (model: GC-14B, manufacturer: Japan Shimadzu). The selectivity of the product 2-chloro-5-chloromethylpyridine is 90~99%, as shown in Table 2.

[0031] Table 2 The influence of the better process conditions on the reaction

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com