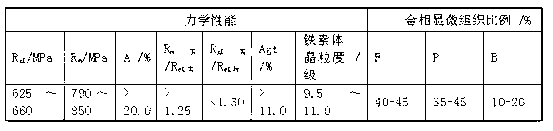

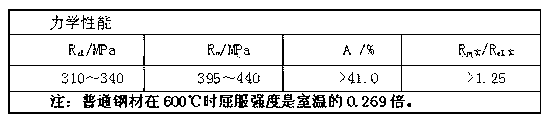

600MPa high-performance fire-resistant aseismic reinforcing steel bar for concrete and production thereof

An anti-seismic reinforcement and high-performance technology, which is applied in the field of steel manufacturing for construction, can solve problems such as inability to meet chemical composition and process performance requirements, high content of carbon, microalloys and alloys, and inconsistent microstructure, etc. Strong applicability and controllability, improved plasticity and toughness, and improved passivation and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

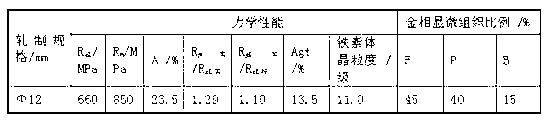

Embodiment 1

[0028] A. Molten steel smelting: After adding molten iron, scrap steel and pig iron into a 50-ton LD oxygen converter, carry out conventional top-bottom composite blowing, and then add commercially available active lime, light-burned dolomite and magnesite balls according to conventional quantities for slagging; The carbon content at the control end point is 0.04wt%, and the tapping temperature is 1668°C; before tapping, add refining slag and fluorite to the bottom of the ladle, and the amount of refining slag added is: 1.6kg / t 钢 , the amount of fluorite added: 0.4kg / t 钢 ;The conventional slag washing and full bottom argon blowing process are adopted when tapping the steel, and the argon flow rate is controlled at 50NL / min. When the molten steel in the ladle is greater than 1 / 4, the following substances are added to the ladle in turn: 1.0kg / t 钢 Add the following mass ratio of silicon-calcium-barium composite deoxidizer: Si 52.5wt%, Ca 12.3wt%, Ba 11.5wt%; according to 10.5kg / t...

Embodiment 2

[0040] A. Molten steel smelting: After adding molten iron, scrap steel and pig iron into a 50-ton LD oxygen converter, carry out conventional top-bottom composite blowing, and then add active lime, light-burned dolomite and magnesite balls to make slag as usual; the carbon at the control end point is 0.06wt%, the tapping temperature is 1665°C; adding refining slag and fluorite to the bottom of the ladle before tapping, the amount of refining slag added: 1.6kg / t 钢 , the amount of fluorite added: 0.4kg / t 钢 ; When tapping, adopt slag washing and full bottom argon blowing process, the flow rate of argon gas is controlled at 63NL / min, when the amount of molten steel in the ladle is greater than 1 / 4, add the following substances to the ladle in turn: 1.3kg / t 钢 Add the following mass ratio of silicon-calcium-barium composite deoxidizer: Si 52.5wt%, Ca 12.3wt%, Ba 11.5wt%; according to 12.8kg / t 钢 The amount of adding Mn content is 76.5wt% high-carbon ferromanganese; by 8.5kg / t 钢 The...

Embodiment 3

[0053] A. Molten steel smelting: After adding molten iron, scrap steel and pig iron into a 50-ton LD oxygen converter, carry out conventional top-bottom composite blowing, and then add active lime, light-burned dolomite and magnesite balls to make slag as usual; the carbon at the control end point is 0.07wt%, the tapping temperature is 1662°C; adding refining slag and fluorite to the bottom of the ladle before tapping, the amount of refining slag added: 1.6kg / t 钢 , the amount of fluorite added: 0.4kg / t 钢 ; When tapping, adopt slag washing and full bottom argon blowing process, the flow of argon gas is controlled at 70NL / min, when the amount of molten steel in the ladle is greater than 1 / 4, add the following substances to the ladle in turn: 1.5kg / t 钢 Add the following mass ratio of silicon-calcium-barium composite deoxidizer: Si 52.5wt%, Ca 12.3wt%, Ba 11.5wt%; according to 14.0kg / t 钢 The amount of adding Mn content is 76.5wt% high-carbon ferromanganese; by 9.2kg / t 钢 The amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com