Method for preparing natural material-liposome composite nanofiber based on electrostatic spinning technology

A technology of composite nanofiber and electrospinning technology, which is applied in spinning solution preparation, fiber treatment, rayon manufacturing, etc., can solve the problems of poor stability of bioactive molecules, adverse reactions of patients, short half-life, etc., and achieve low price, Good application prospect, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

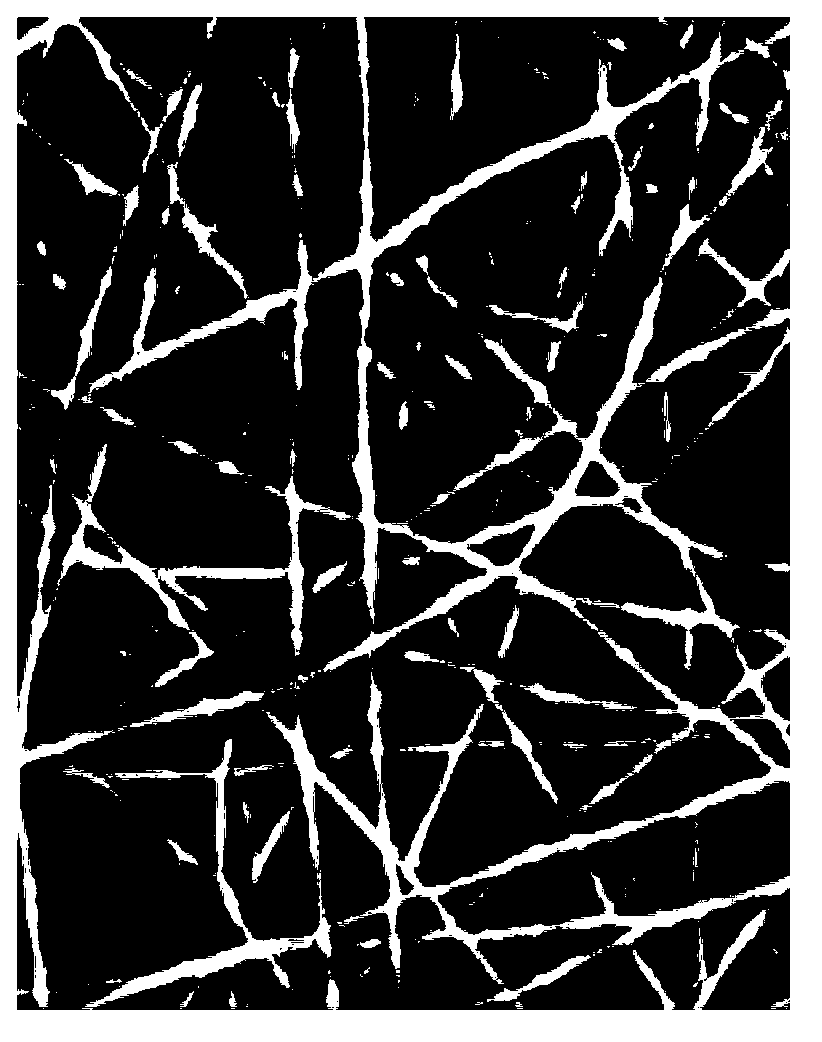

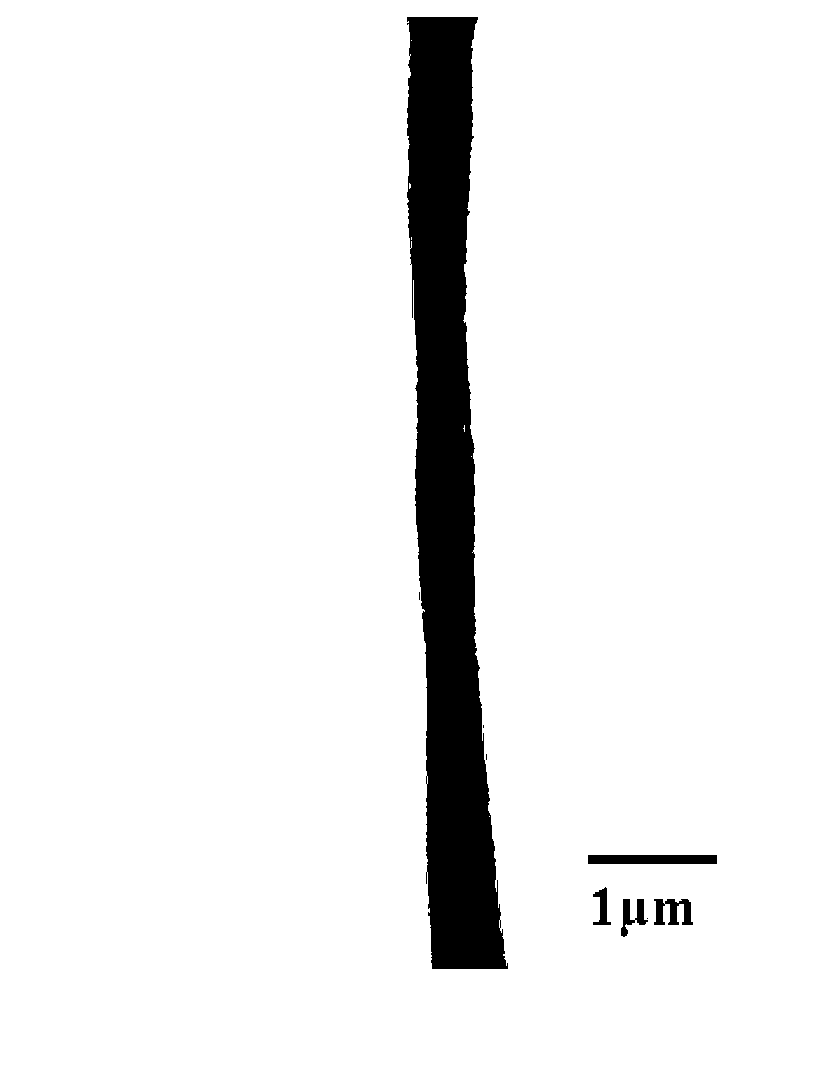

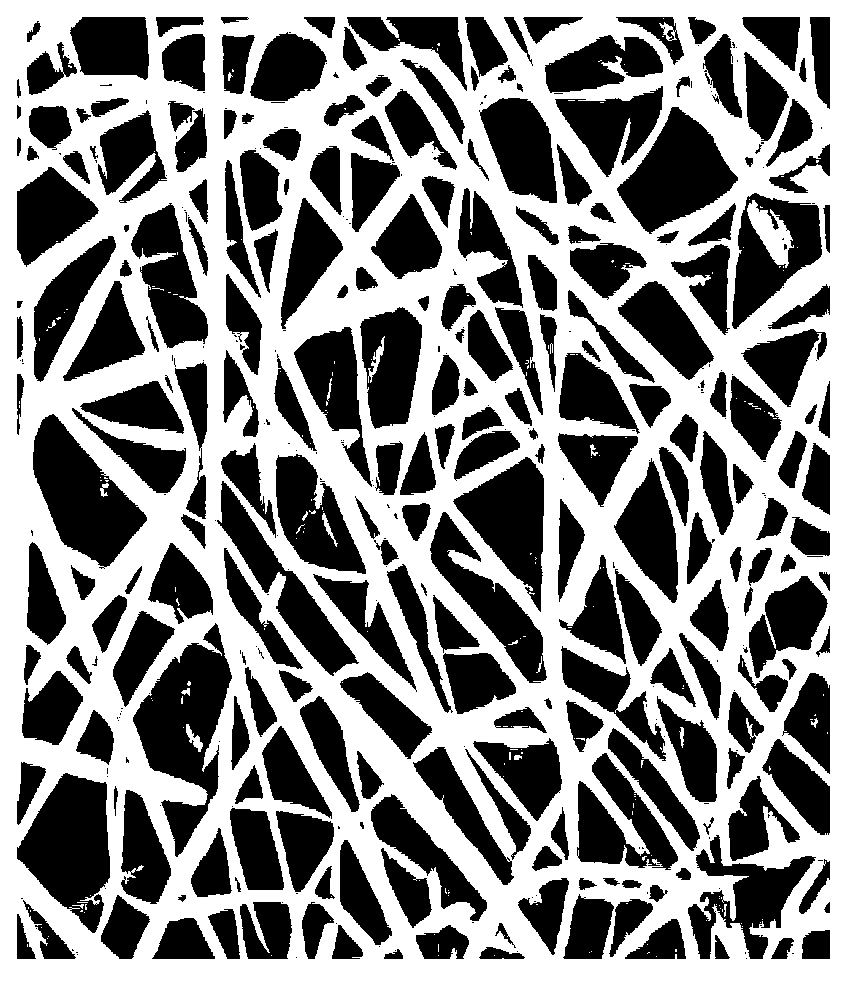

Image

Examples

Embodiment 1

[0033] Liposome-loaded gelatin nanofibrous scaffold

[0034] (1) Prepare liposome microspheres by film dispersion method. Weigh 0.23g of lecithin, 0.15g of cholesterol, and 0.02g of octadecylamine into a 50mL small beaker, add 1.5mL of absolute ethanol, place in a 65°C water bath, stir to dissolve, and evaporate the ethanol under reduced pressure. Liposome membranes were obtained.

[0035] (2) Take 30mL of deionized water in a small beaker, place it in a 65°C water bath, and keep it warm for later use.

[0036] (3) Add the product of step (2) to the small beaker in step (1), stir and hydrate in a water bath at 65°C for 10 minutes. Then place the small beaker on a magnetic stirrer and stir at room temperature for 30 minutes. If the volume of the solution decreases, add deionized water and mix well.

[0037] (4) Ultrasonicating the product of step (3) to obtain a liposome suspension with uniform particle size.

[0038] (5) Use the product in step (4) as a solvent to configur...

Embodiment 2

[0041] Liposome-loaded silk fibroin nanofiber scaffold

[0042] (1) Prepare liposome microspheres by film dispersion method. Weigh 0.3g of lecithin, 0.15g of cholesterol, and 0.02g of octadecylamine into a 50mL small beaker, add 1.5mL of absolute ethanol, place in a 65°C water bath, stir to dissolve, and evaporate the ethanol under reduced pressure. Liposome membranes were obtained.

[0043] (2) Take 30ml of deionized water in a small beaker and place it in a 65°C water bath to keep warm for later use.

[0044] (3) Add the product of step (2) to the small beaker in step (1), stir and hydrate in a water bath at 65°C for 10 minutes. Then place the small beaker on a magnetic stirrer at room temperature and stir for 30 minutes. If the volume of the solution decreases, add deionized water and mix well.

[0045] (4) Ultrasonicating the product of step (3) to obtain a liposome suspension with uniform particle size.

[0046] (5) The product in step (4) was used as a solvent to pre...

Embodiment 3

[0049] Liposome-loaded silk fibroin nanofiber scaffold

[0050] (1) Prepare liposome microspheres by film dispersion method. Weigh 0.3g of lecithin, 0.15g of cholesterol, and 0.02g of octadecylamine into a 50mL small beaker, add 1.5mL of absolute ethanol, place in a 65°C water bath, stir to dissolve, and evaporate the ethanol under reduced pressure. Liposome membranes were obtained.

[0051] (2) Take 50ml of deionized water in a small beaker, add 100μg of plasmid DNA, and place in a 65°C water bath to keep warm until use.

[0052] (3) Add the product of step (2) to the small beaker in step (1), stir and hydrate in a water bath at 65°C for 10 minutes. Then place the small beaker on a magnetic stirrer at room temperature and stir for 60 minutes. If the volume of the solution decreases, add deionized water and mix well.

[0053] (4) Ultrasonicating the product of step (3) to obtain a liposome suspension with uniform particle size.

[0054] (5) The product in step (4) was used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com