Static conductive lining for repairing product oil pipeline and manufacturing method thereof

A technology for pipeline repair and refined oil, applied in the field of pipeline engineering, can solve the problems that the physical and mechanical properties of materials cannot meet the standards, the performance of conductive fillers is very limited, and the electrical conductivity of oil products is unqualified. It can achieve a wide range of hardness, excellent mechanical strength, Outstanding shock absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions and effects of the present invention will be further described below in conjunction with the examples.

[0025] raw material

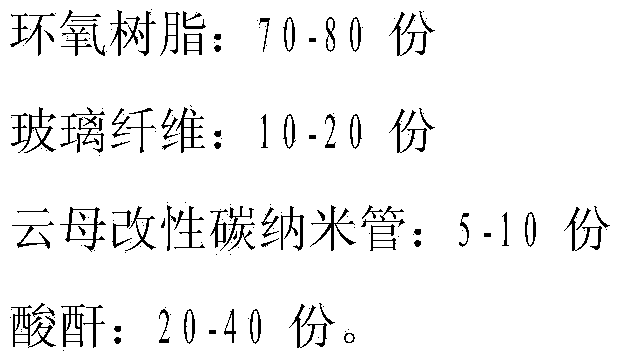

[0026] E6101 epoxy resin: 80 parts, acid anhydride: 40 parts, glass fiber: 20 parts, mica modified carbon nanotube: 10 parts; TPU-nylon fiber composite material.

[0027] Manufacturing method: Add the mica-modified carbon nanotube filler compounded with mica to the E6101 epoxy resin according to the ratio required by the formula, add glass fiber reinforcement material, and then add high-temperature curing agent anhydride, mix well, and use it to seal the tubular TPU-nylon fibers attached to the surface of the thermoplastic polyurethane elastomer are fully infiltrated, and the tubular thermoplastic polyurethane elastomer needs to match the inner diameter of the pipeline to be treated; then one end of the thermoplastic polyurethane elastomer is closed, reversed and placed in the pipeline to be repaired, and the pressure is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com