Preparation method of foamless self-adhesive for KT board (foam board)

A technology of adhesive and rubber, which is applied in the field of preparation of non-foaming adhesive for KT boards, can solve problems such as insufficient adhesion of acrylate pressure-sensitive adhesives, and achieve improved residual bonding rate, good wear resistance, and cohesive strength high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

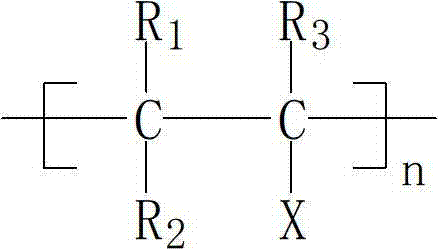

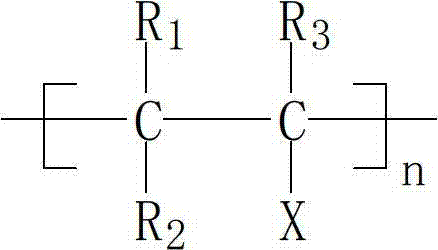

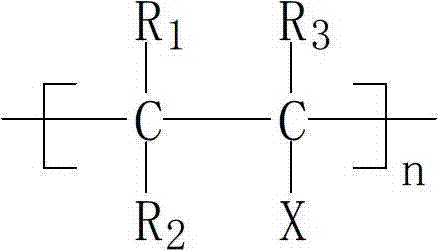

Image

Examples

Embodiment 1

[0056] Rubber / acrylate graft copolymer pressure-sensitive adhesives and non-polar group grafted acrylate pressure-sensitive adhesives are rolled to treat the release layer of the release paper as follows:

[0057] The synthesis process of rubber / acrylate graft copolymer pressure-sensitive adhesive is as follows: masticate natural rubber on an open mill, mix evenly and discharge the material, then use toluene to heat up and dissolve the mixed rubber cut into small pieces, and set aside ; Accurately weigh and dissolve 10 parts of vinyl acetate, 40 parts of ethyl acrylate, 1 part of methacrylic acid, 0.5 parts of dibenzoyl peroxide, 2 parts of propylene oxide, and 0.1 part of butyl titanate in 10 parts of ethyl acetate , mix evenly, and set aside; add the prepared rubber solution into the reactor, stir and heat up to the polymerization temperature of 50°C, take 1 / 5 of the above-mentioned mixed monomer with dibenzoyl peroxide added into the reactor Stir continuously, add the remai...

Embodiment 2

[0062] Rubber / acrylate graft copolymer pressure-sensitive adhesives and non-polar group grafted acrylate pressure-sensitive adhesives are rolled to treat the release layer of the release paper as follows:

[0063] The synthesis process of rubber / acrylate graft copolymer pressure-sensitive adhesive is as follows: masticate nitrile rubber on an open mill, then mix evenly and discharge the material, then use toluene to dissolve the mixed rubber cut into small pieces, Standby; Accurately weigh 10 parts of acrylamide, 40 parts of 2-ethylhexyl acrylate, 1 part of hydroxypropyl methacrylate, 0.5 parts of dibenzoyl peroxide, 3 parts of propylene oxide, and butyl titanate Dissolve 0.2 parts in 10 parts of toluene, mix well, and set aside; add the prepared rubber solution into the reactor, stir and heat up to the polymerization temperature of 50°C, take 1 / 5 was added to the reactor and stirred continuously, and after 1 hour, the remaining mixed monomers were added dropwise, and reacted...

Embodiment 3

[0068] Rubber / acrylate graft copolymer pressure-sensitive adhesives and non-polar group grafted acrylate pressure-sensitive adhesives are rolled to treat the release layer of the release paper as follows:

[0069] The synthesis process of rubber / acrylate graft copolymer pressure-sensitive adhesive is as follows: masticate styrene-butadiene rubber on an open mill, and then mix evenly before discharging, and then use toluene to heat up and dissolve the mixed rubber cut into small pieces. Standby; accurately weigh 30 parts of acrylonitrile, 60 parts of butyl acrylate, 5 parts of acrylic acid, 6 parts of dibenzoyl peroxide, 5 parts of propylene oxide, and 0.3 parts of butyl titanate in 30 parts of toluene, mix Uniform, ready for use; add the prepared rubber solution into the reactor, stir and heat up to the polymerization temperature of 100°C, take 4 / 5 of the above-mentioned mixed monomer with dibenzoyl peroxide added into the reactor and keep stirring, After 3 hours, add the rema...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com