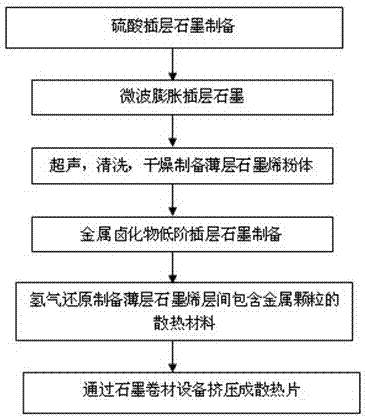

Preparation method for high heat conduction and radiation material by intercalating metal particles between layers of thin-layer graphene

A technology of thin-layer graphene and metal particles, which is applied in the field of materials, can solve the problems of inability to conduct heat, achieve the effects of low environmental pollution, low cost, and improved heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Weigh 4 g of graphite (10 mesh), 1 mL of 30% hydrogen peroxide, stir well, add 20 mL of oleum containing 20% sulfur trioxide, stir at 30 °C for 1 h, filter, wash with water, 80 Bake at ℃ for 4 h;

[0034] Microwave the above dried sulfuric acid intercalated graphite residues to obtain worm-like graphene aggregates, ultrasonicate in organic solvents such as nitrogen-methylpyrrolidone, ethanol, acetone or water at 150 W power, and ultrasonicate for 2 minutes to obtain cleavage thin-layer graphene, freeze-dried;

[0035] The above two steps are repeated one or more times to ensure that the number of graphene layers prepared is 2-50 layers, the sheet size is 2-300 microns, and the carbon-oxygen ratio is 20-100;

[0036] Weigh 500 mg of the above-prepared thin-layer graphene, 1.0 g NiCl 2 Placed in a 50 ml reaction kettle. And put it in an oven at 300 °C for 24 h. A thin-layer graphene intercalation material intercalated with nickel chloride was prepared.

[0037] The...

Embodiment 2

[0041] Weigh 6 g of graphite (325 mesh), 1.5 mL of 30% hydrogen peroxide, stir well, add 10 mL of oleum containing 20% sulfur trioxide, stir at 50 °C for 1 h, filter, wash with water, Bake at 100°C for 4 h.

[0042] Microwave the sulfuric acid intercalated graphite residues dried above to obtain worm-like graphene aggregates, and ultrasonicate them in nitrogen-methylpyrrolidone, ethanol, acetone and other organic solvents or water at 500 W power, and the ultrasonic time is 60 minutes to obtain cleavage thin-layer graphene, freeze-dried.

[0043] The above two steps are repeated one or more times to ensure that the number of prepared graphene layers is 2-50, the sheet size is 2-300 microns, and the carbon-oxygen ratio is 20-100.

[0044] Weigh 500 mg of the above-prepared thin-layer graphene, 1.0 g FeCl 3 Placed in a 50 ml reaction kettle. And put it in an oven at 300 °C for 24 h. A thin-layer graphene intercalation material intercalated with ferric chloride was prepared....

Embodiment 3

[0049]Weigh 3 g of graphite (500 μm in lateral dimension), 0.5 mL of 40% hydrogen peroxide, stir well, add 5 mL of 96% concentrated sulfuric acid, 10 g of phosphorus pentoxide, stir at 30 °C for 1 h, filter , washed with water, and dried at 80°C for 4 h.

[0050] Microwave the above dried sulfuric acid intercalated graphite residues to obtain worm-like graphene aggregates, ultrasonicate in organic solvents such as nitrogen-methylpyrrolidone, ethanol, acetone or water with 50 W power, and ultrasonicate for 4 hours to obtain cleavage thin-layer graphene, freeze-dried.

[0051] The above two steps are repeated one or more times to ensure that the number of prepared graphene layers is 2-50, the sheet size is 2-300 microns, and the carbon-oxygen ratio is 20-100.

[0052] Weigh 1.0 g of the above-prepared thin-layer graphene, 500 mg CuCl 2 Placed in a 50 ml reaction kettle. And put it in an oven at 200 °C for 24 h. A thin-layer graphene intercalation material intercalated with c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com