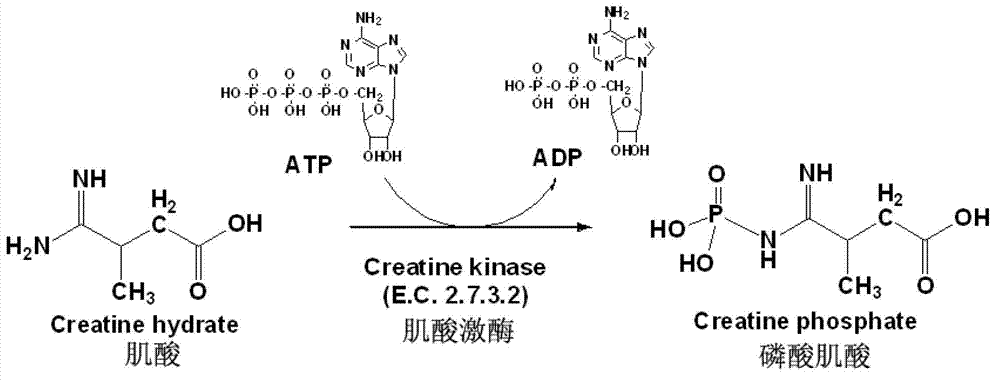

Method for producing phosphocreatine by microbial enzyme method

A microbial enzyme and creatine phosphate technology, which is applied in the field of biotechnology to produce creatine phosphate, can solve the problems of affecting the yield of creatine phosphate, difficulty in separation and extraction process, and inability to guarantee optimal conditions, etc., and achieve simple process steps and safe operation , the effect of good industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

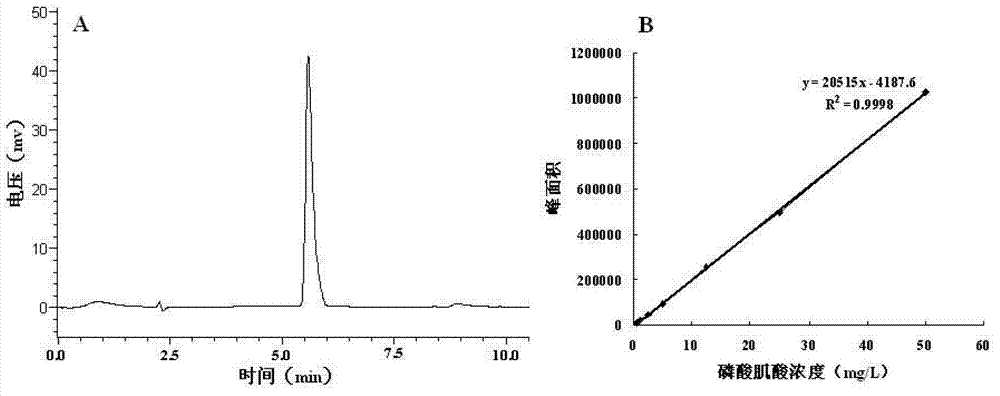

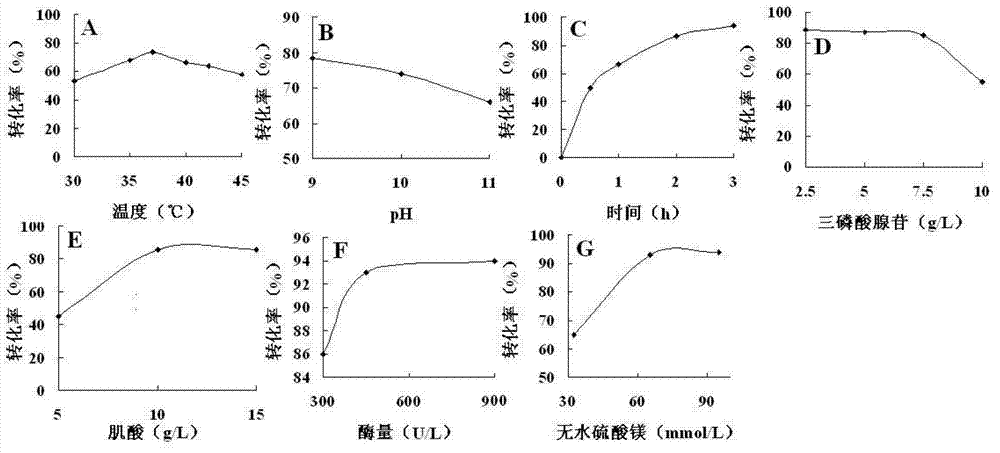

Method used

Image

Examples

Embodiment 1

[0050] The construction of embodiment 1 genetically engineered bacterium Escherichia coli and the expression of recombinant creatine kinase

[0051] According to the creatine kinase gene sequence of mouse muscle included in the NCBI database, the upstream primer CPK1: 5'-GGGAAT TCC ATA TGC CGT TCG GCA ACA CCC ACA AC-3' (SEQ ID No.1) and the downstream primer CPK2: 5 were designed '-CCG CTC GAG CTT CTG CGC GGG GAT CAT GTC GTC G-3' (SEQ ID No. 2). Total RNA was extracted from mouse skeletal muscle, and cDNA was prepared by reverse transcription. Using mouse skeletal muscle cDNA as a template, the creatine kinase gene was amplified by PCR. The recombinant expression plasmid pET-21a(+)-CPK was constructed by genetic engineering method. The recombinant expression vector pET-21a(+)-CPK was transformed into E.coli BL21(DE3) to obtain a genetically engineered strain.

[0052] The positive recombinant strains were inoculated into 4 mL of LB medium containing 100 μg / mL ampicillin for...

Embodiment 2

[0054] Embodiment 2 Fermentation of recombinant creatine kinase genetically engineered recombinant bacteria

[0055] The recombinant Escherichia coli in Example 1 was inoculated in 4 mL of LB medium containing 100 μg / mL ampicillin and cultivated overnight as a primary seed liquid; then inserted into 100 mL of LB culture containing 100 μg / mL ampicillin with 1% transfer amount culture medium at 37°C, 200rpm for 8-12h as the secondary seed liquid; the secondary seed liquid was transferred to a 100L fermenter with 1% inoculum, the fermentation medium was fresh LB medium, and the culture temperature was 37°C. The initial rotation speed is 300rpm, and the initial pH is 7.2. Samples were taken regularly, and when the OD600nm of the bacterial solution reached 1.0-1.2, IPTG induction solution with a final concentration of 1 mM was added for induction. The fermentation liquid in the lower tank was centrifuged at 3,000 rpm for 15 minutes at 4°C to collect the bacterial cells, and the fe...

Embodiment 3

[0056] Example 3 Preparation of Lysate of Recombinant Creatine Kinase Genetic Engineering Recombinant Bacteria

[0057] According to Example 2, ferment recombinant creatine kinase genetically engineered recombinant bacteria to obtain fermented cells, collect the cells and perform ultrasonic crushing to obtain crude enzyme liquid of creatine kinase, and measure its enzyme activity according to method 1, and the enzyme activity is about 6 U / mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com