Method for preparing ultrafine tungsten oxide nanopowder by recovering waste hard alloy with hydrothermal method

A technology of cemented carbide and nano-powder, which is applied in the direction of improving process efficiency, etc., to achieve the effects of low energy consumption, good performance and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

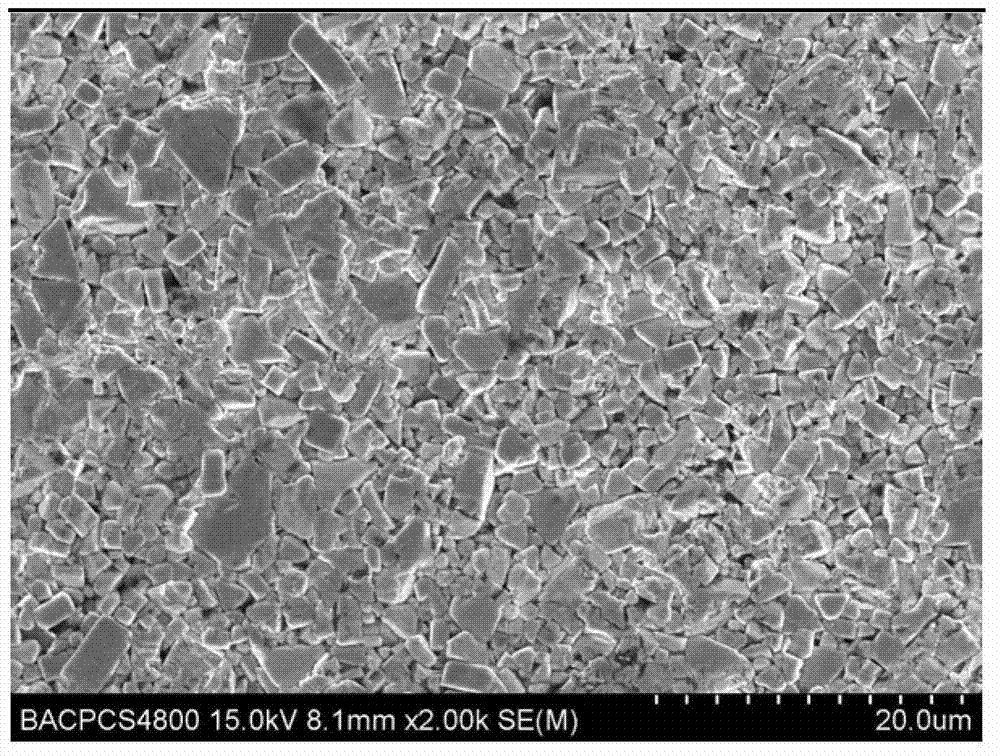

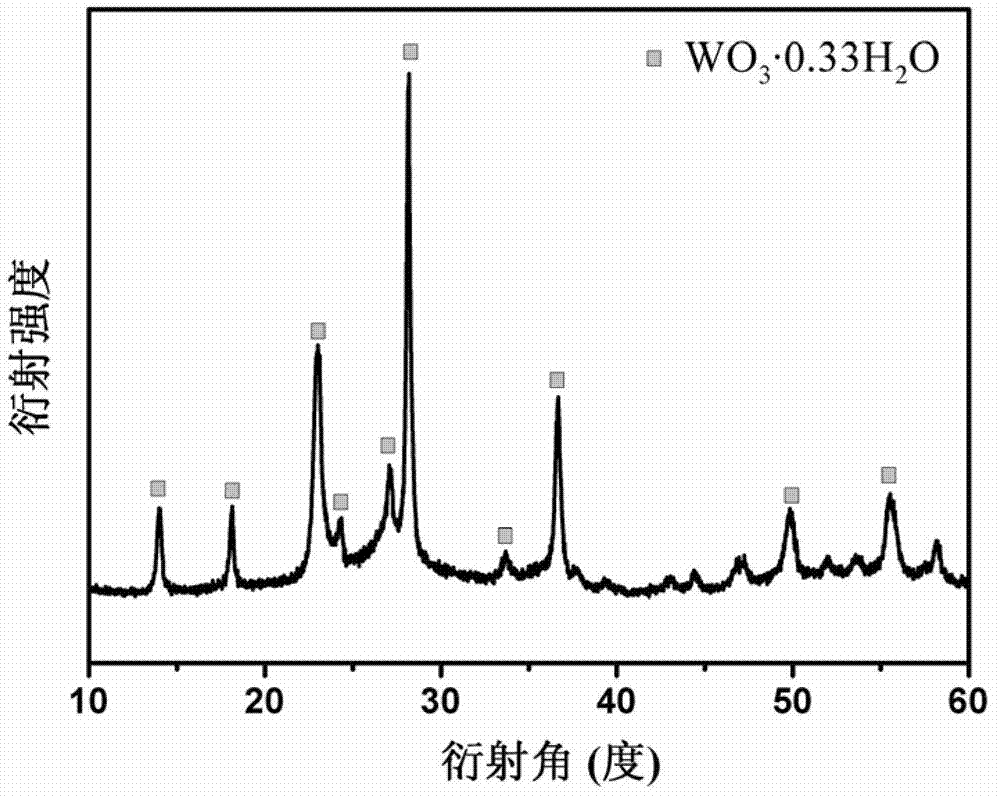

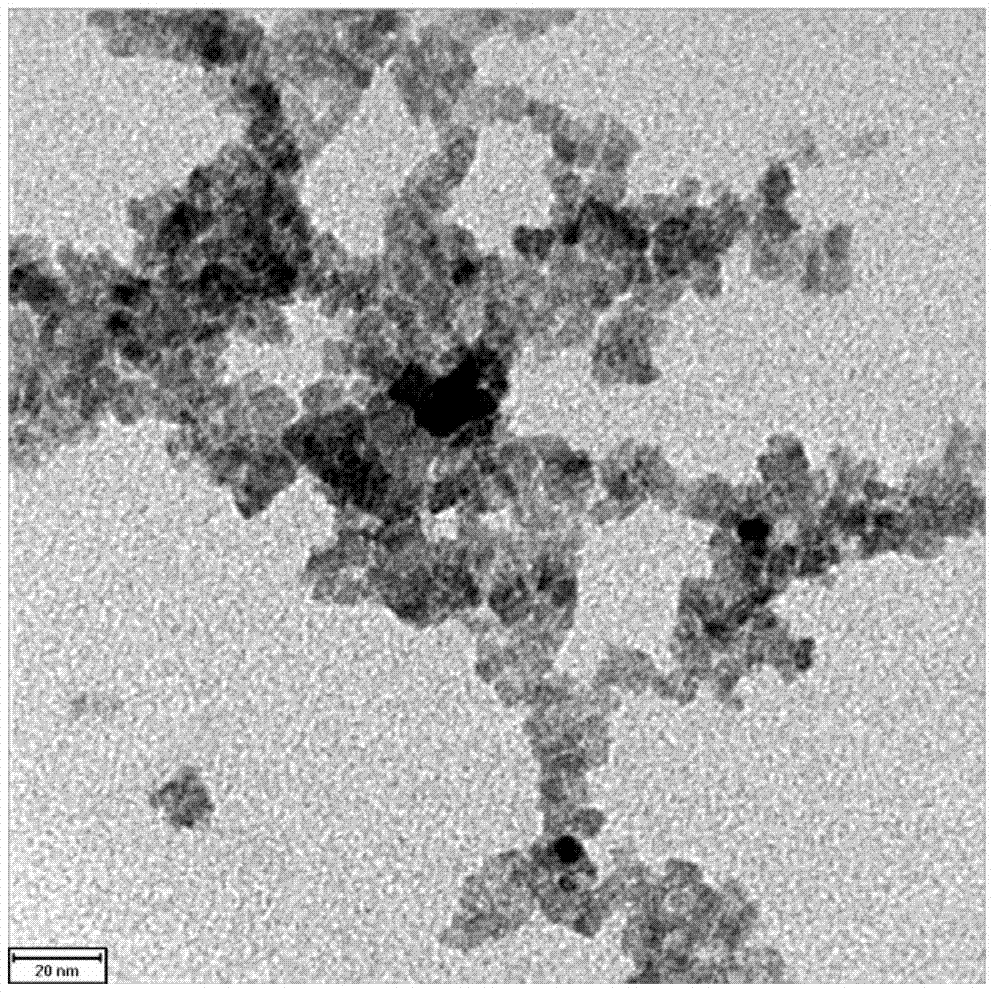

[0017] Embodiment 1: be that the cemented carbide of 3% with cobalt content (SEM photo sees figure 1 ) 10.0g and 0.5g NaF were added to the reactor, and 16M HNO was added 3 10ml and 9.9M H 2 o 2 Add 10ml into the reaction kettle, then put the reaction kettle into the oven and heat it to 165°C, keep it warm for 20h, after the temperature drops to room temperature, open the reaction kettle, separate the solid and liquid phases with filter paper, and rinse several times with distilled water , the obtained solid phase was dried at 60°C for 6h and then ground in a mortar to obtain ultrafine WO 3 0.33H 2 0 nanometer powder, its specific surface area reached 90m 2 g -1 . Income WO 3 0.33H 2 The XRD analysis result of 0 powder is as follows figure 2 As shown, the TEM photographs are as image 3 shown.

[0018] With the obtained WO 3 0.33H 2 0 nanometer powder was used as an adsorbent to conduct adsorption experiments on different concentrations of methylene blue soluti...

Embodiment 2

[0019] Example 2: Add 10.25 g of cemented carbide with 10% cobalt and 1.0 g NaF to the reactor, add 16M HNO 3 5ml and 9.9M HO 2 o 2 Add 25ml into the reaction kettle, then put the reaction kettle into the oven and heat it to 200°C, keep it warm for 6h, after the temperature drops to room temperature, open the reaction kettle, separate the solid and liquid phases with filter paper, and rinse several times with distilled water , the obtained solid phase was dried at 60°C for 6h and then ground in a mortar to obtain ultrafine WO 3 0.33H 2 0 nanometer powder, its specific surface area is 80m 2 g -1 .

[0020] With the obtained WO 3 0.33H 2 0 nanometer powder as an adsorbent for different concentrations of methylene blue solutions and Pb-containing 2+ The solution was subjected to adsorption experiments, and the WO 3 0.33H 2 0 powder for methylene blue and Pb 2+ The maximum adsorption capacity of 115 mg g -1 , 211 mg g -1 .

Embodiment 3

[0021] Embodiment 3: adding 11.5g of cemented carbide and 2.3g of NaF to the reactor with a cobalt content of 15%, adding the HNO of 16M 3 25ml and 9.9M H 2 o 2 Add 5ml into the reaction kettle, then put the reaction kettle into the oven and heat it to 120°C, keep it warm for 48h, after the temperature drops to room temperature, open the reaction kettle, separate the solid and liquid phases with filter paper, and rinse several times with distilled water , the obtained solid phase was dried at 60°C for 6h and then ground in a mortar to obtain ultrafine WO 3 0.33H 2 0 nanometer powder, its specific surface area is 70m 2 g -1 .

[0022] With the obtained WO 3 0.33H 2 0 nanometer powder was used as an adsorbent, and the methylene blue solution with different concentrations was mixed with Pb 2+ The solution was subjected to adsorption experiments, and the WO 3 0.33H 2 0 powder for methylene blue and Pb 2+ The maximum adsorption capacity was 95.2 mg g -1 、198mg g -1 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com