Infrared spontaneously heating floor and process thereof

A processing technology and self-heating technology, applied in wood processing equipment, heating methods, electric heating systems, etc., can solve problems such as easy cracking, accelerated machine aging, poor contact, etc., achieve anti-collision and waterproof, and prolong service life , the effect of preventing heat penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

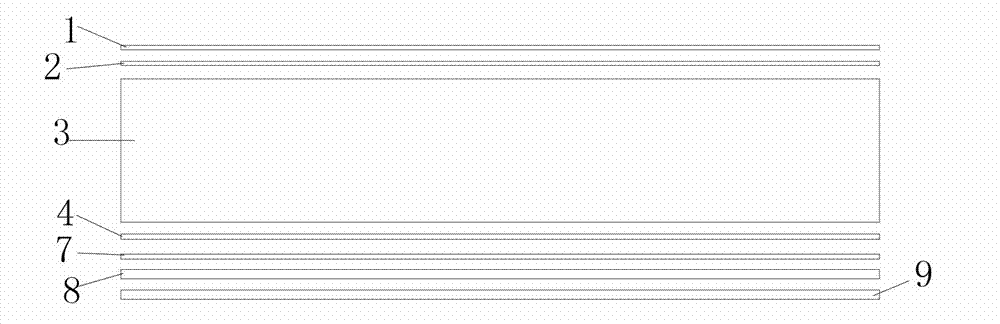

[0102] as attached figure 1 , 2 As shown in and 3, an infrared self-heating floor includes a wear-resistant layer 1, a decorative layer 2, a base material 3 and a balance layer 4 arranged layer by layer from top to bottom, and the decorative layer 2 and the base material 3 are flame-retardant Processing; the bottom surface of the base material 3 is provided with a wire slot with a notch downward, and the position of the balance layer 4 corresponding to the wire slot is hollowed out; the interconnected power line 5 and carbon fiber cable 6 are arranged in the wire slot; The carbon fiber in the carbon fiber cable 6 is filament carbon fiber; the input end and the output end of the power cord 5 are respectively provided with USB connectors; the infrared reflective film 7 and the heat insulation layer are sequentially arranged below the balance layer 4 from top to bottom. 8 and insulation layer 9.

[0103] The bottom surface of the base material 3 is provided with three longitudi...

Embodiment 2

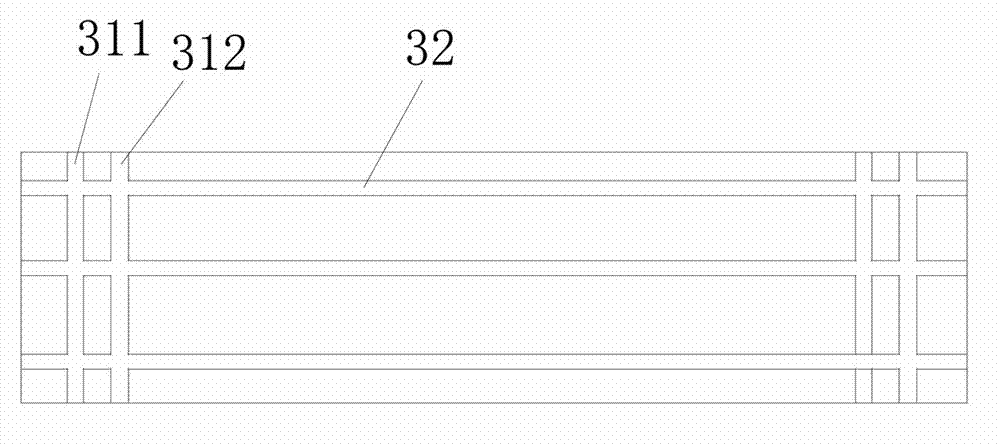

[0132] as attached figure 1 , 4 As shown in and 5, the difference from the first embodiment is that the base material 3 is provided with two longitudinal wire grooves 32, and a horizontal wire groove 31 is respectively provided at both ends of the base material 3; the one horizontal wire groove 31 and the two A carbon fiber cable 6 arranged in a U shape is arranged in one longitudinal slot 32; two power lines 5 are arranged in the other horizontal slot 31; two ends of the two power lines 5 are insulated by a two-wire USB connector The two ends of the carbon fiber cable 6 are electrically connected to the two power lines 5 respectively. The material of the base material 3 is maple wood.

[0133] The processing technology of the infrared self-heating floor includes the following processing steps:

[0134] A, will be used to make the sheet metal cold and heat-resistant treatment process of base material 3:

[0135] a. Boil the board in hot water at 100°C for 3.5 hours;

[01...

Embodiment 3

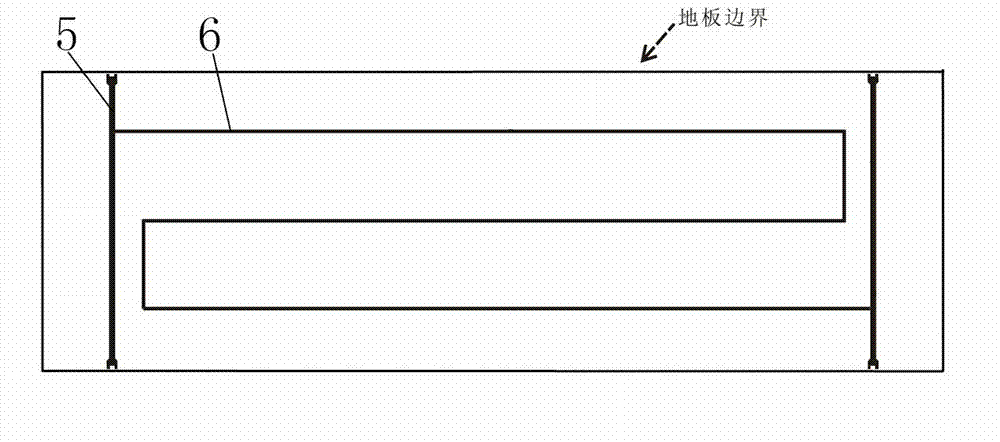

[0159] as attached figure 1 , 6 As shown in 7, the above embodiment is different in that two longitudinal wire slots 32 are provided on the base material 3, two horizontal wire slots 31 are provided at one end of the base material 3, and one horizontal wire slot 31 is provided at the other end; There is only a single horizontal wire groove 31 in the two longitudinal wire slots 32 and on the substrate 3. A U-shaped carbon fiber cable 6 is arranged in the horizontal wire groove 31 at one end, and the two horizontal wire grooves 31 at the other end and the two Two longitudinal wire slots 32 located between the two horizontal wire slots 31 are provided with two Z-shaped staggered power cords 5, the two ends of the power cords 5 are connected with USB connectors, and the two ends of the carbon fiber cable 6 are They are respectively electrically connected to two power lines 5 . The material of the base material 3 is teak.

[0160] The processing technology of the infrared self-h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com