Low-concentration flue gas infra-red analyzer and detection method

An infrared analyzer, low-concentration technology, applied in the analysis of materials, material analysis through optical means, instruments, etc., can solve the problem of easy-to-interference discharge detector measurement accuracy, high mirror structure and process requirements, and difficult low-concentration Gas measurement and other issues to achieve the effect of ensuring detection accuracy and sensitivity, improving flatness, and reducing drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

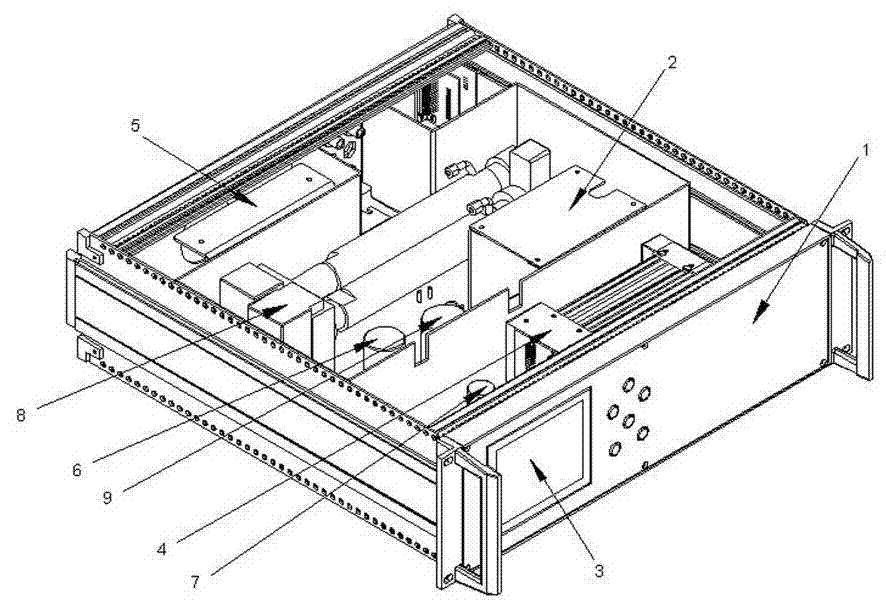

[0033] figure 1 It is a structural layout diagram of the flue gas analyzer in the embodiment of the present invention, as shown in the figure, including a chassis 1, a heating control unit 2, an output display unit 3, a data acquisition and processing unit 4, and a power supply 5; a flue gas pipe is arranged in the chassis 1 The water filter device 6 is installed at the inlet of the flue gas pipeline, and the temperature sensor, pressure sensor, humidity sensor, oxygen sensor 7, and gaseous pollutant detection unit 8 are respectively installed on the flue gas pipeline; a flue gas multi-parameter The measuring chamber 9, the temperature sensor, the pressure sensor and the humidity sensor are all set in the flue gas multi-parameter measuring chamber 9.

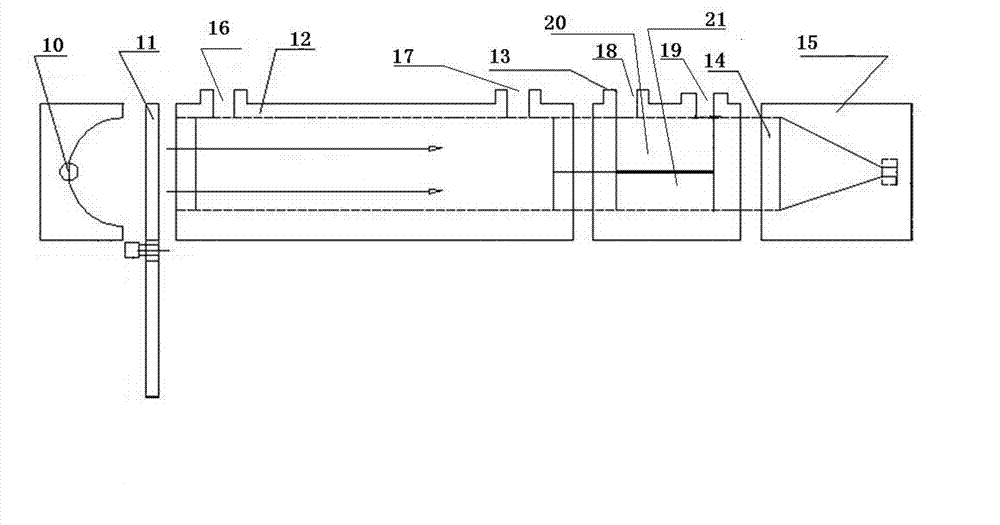

[0034]The gaseous pollutant detection unit 8 of the present embodiment includes an infrared light source 10 and a light chopper 11 arranged behind it, and is arranged in sequence along the optical path behind the light chopper t...

Embodiment 2

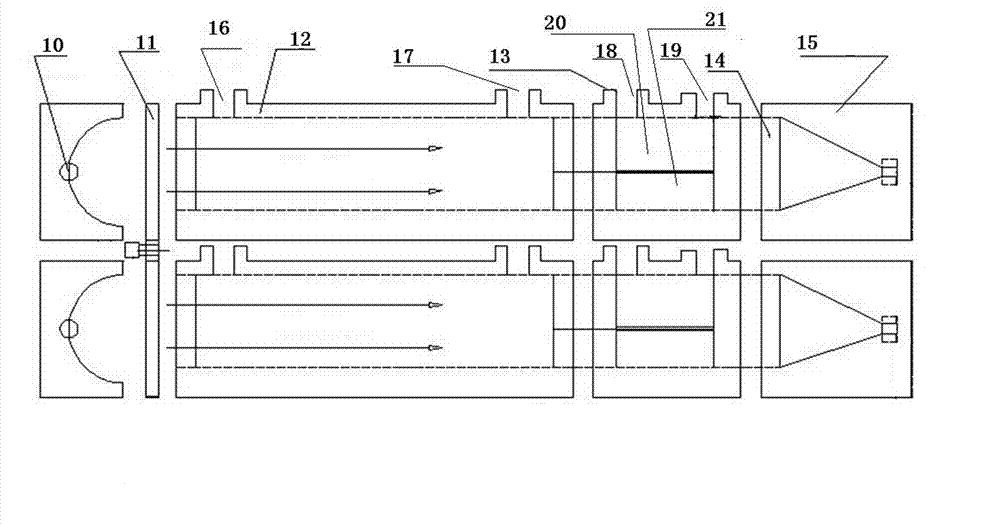

[0038] Such as image 3 As shown, in order to improve the utilization efficiency of the flue gas analyzer, two gaseous pollutant detection units 8 are arranged in parallel. The standard gas and select the corresponding detection sensor can be preferably packaged NO and CO standard gas.

Embodiment 3

[0040] The detection sensor 15 has a measurement range of 0~100~3000 mg / m 3 (dual-range) NO sensor; the reference cell 21 encapsulates NO standard gas. The data acquisition and processing unit includes a front-end control system, a circuit system, and a software analysis and calculation system; the output display unit includes a display screen, buttons, a communication unit, and a communication serial port. The water filtering device 6 is a water filtering membrane, which can block the passage of liquid water in the flue gas and protect the sensors in the cabinet. The heating control unit 2 heats the flue gas pipeline inside the cabinet to ensure that the system is in a constant temperature state. After the flue gas enters the chassis, the NO concentration can be measured after the temperature sensor, pressure sensor, humidity sensor, and oxygen sensor measure various background parameters.

[0041] Selection of the length of the absorption cell 12: it is related to the abso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com