Harmless mud processing method for sewage treatment plant

A harmless treatment and sewage treatment plant technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of high energy consumption, secondary pollution, high cost, land occupation, etc., and achieve the purpose of inhibiting bacterial reproduction and even death, Increased mechanical strength, good for growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

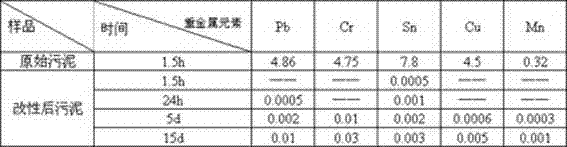

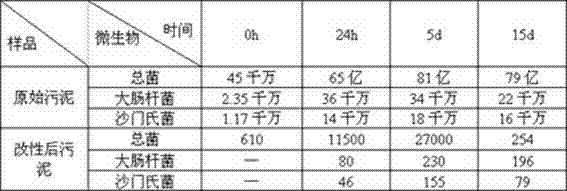

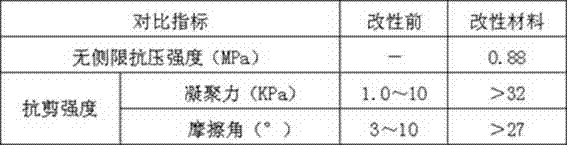

Examples

Embodiment 1

[0019] 1. Prepare cementitious material, the steps are as follows:

[0020] (1) The weight percentage of building material components is: 50-80% of fluorogypsum, 5%-20% of cement clinker, 5-15% of alkaline ash, 10-20% of water-quenched slag, 5-15% of fly ash, 0.5-3% coagulant; the sum of the weight percentages of the above components is 100%;

[0021] (2) Neutralize the tailings of the AHF reaction process - fluorogypsum to pH > 7, and send it to the silo as the main raw material for standby;

[0022] (3) Cement clinker, alkaline ash, water-quenched slag, and fly ash are sent to the silo for standby;

[0023] (4) Put the above-mentioned raw materials into the hot air drying device according to the ratio through the automatic metering screw to remove the surface water and enter the mixing bin;

[0024] (5) After drying, the mixture enters the grinder and grinds to a fineness > 200 mesh;

[0025] (6) Add a coagulant to the ground mixture, enter the powder mixer and mix evenly...

Embodiment 2

[0042] A method for harmless treatment of sludge in a sewage treatment plant, the steps of which are as follows: adding water-retaining materials to the original sludge to reduce the water content of the sludge to below 65%, and then adding cementing materials externally, under normal temperature and pressure Mix evenly and air dry naturally.

[0043] The mass ratio of the three when mixed is sludge (water content 95%): cementing material: water-retaining material = 100:15-30:0.05.

[0044] The water-retaining material is a high-magnification water-absorbing resin provided by Wuhan Yuancheng Gongchuang Technology Co., Ltd.

[0045] The cementing material is mainly made of industrial fluorine gypsum, supplemented by cement clinker, metallurgical industry alkaline ash, water quenching slag, power industry fly ash, coagulation accelerator and the like. The weight percentage of each component of the cementing material is: 50% fluorogypsum; 10% cement clinker, 12% alkaline ash; 15% ...

Embodiment 3

[0054] The harmless treatment method for sludge in sewage treatment plants, the steps are as follows: add water-retaining materials to the original sludge to reduce the water content of the sludge to less than 65%, then add cementing materials, and mix uniformly under normal temperature and pressure. Stir and dry naturally;

[0055] The mass ratio of the three when mixed is sludge (water content 70%): cementing material: water-retaining material = 100:15-30:0.01.

[0056] The water-retaining materials are polyacrylates and vinyl acetate copolymers.

[0057] The cementing material is mainly made of industrial gypsum, supplemented by cement clinker, metallurgical industry alkaline ash, water quenching slag, power industry fly ash, coagulation accelerator and the like. The weight percentage of each component of the cementing material is: 73.5% of phosphogypsum, 5% of cement clinker, 6% of alkaline ash, 10% of water quenching slag, 5% of fly ash, and 0.5% of coagulant. Described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com