Peanut special microbial fertilizer and production method thereof

A technology of microbial fertilizer and compound microbial agent, which is applied in the direction of application, fertilization device, fertilizer mixture, etc., to achieve the effects of inhibiting growth, protecting crop root system, and reducing soil salinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

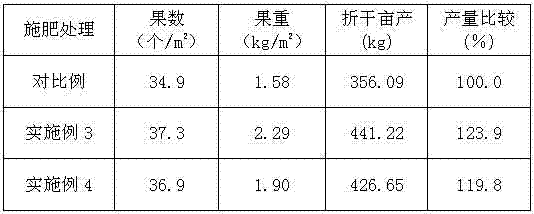

Examples

Embodiment 1

[0059] Example 1: Peanut-specific microbial fertilizer, nitrogen, phosphorus pentoxide, and potassium oxide contents were 19%, 6%, and 13% respectively, all of which were percentages by mass.

[0060] Raw material component parts by weight are as follows:

[0061] 8 parts of compound microbial agent,

[0062] 8 parts peat soil,

[0063] 40 parts of urea,

[0064] Calcium magnesium phosphate fertilizer 10 parts,

[0065] 8 parts of monoammonium phosphate,

[0066] Potassium sulfate 25 parts,

[0067] 1 part bentonite.

[0068] Preparation method: ①Cultivation of a single bacterial agent

[0069] Take out the strains preserved in the 4°C refrigerator by the test tube slant preservation method, expand them to fresh test tube beef extract peptone slant medium, cultivate them in a 30°C incubator for 2-4 days, and inoculate them with 5g of beef extract, peptone 5g, sodium chloride 5g, water 1L pH is 7.2 in the culture solution for shaker culture; the number of bacteria in the...

Embodiment 2

[0080] Example 2: Special microbial fertilizer for peanuts, the content of nitrogen, phosphorus pentoxide and potassium oxide are respectively 18%, 9% and 11%, all of which are percentages by mass.

[0081] Raw material component parts by weight are as follows:

[0082] 10 parts of compound microbial agent,

[0083] 8 parts peat soil,

[0084] 35 parts of urea,

[0085] 8 parts of calcium magnesium phosphate fertilizer,

[0086] 15 parts of monoammonium phosphate,

[0087] Potassium sulfate 22 parts,

[0088] Bentonite 2 parts.

[0089] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com