Method and device for preparing active calcium hydride

A calcium hydride and active technology, applied in the direction of alkali metal/alkaline earth metal/beryllium/magnesium hydride, etc., can solve the problems of difficult to grasp the composition of the final reaction product, difficult to control the reaction conditions, low production efficiency, etc., to achieve mild operating conditions, The effect of less resource consumption and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 One of the preparation experiments of active calcium hydride.

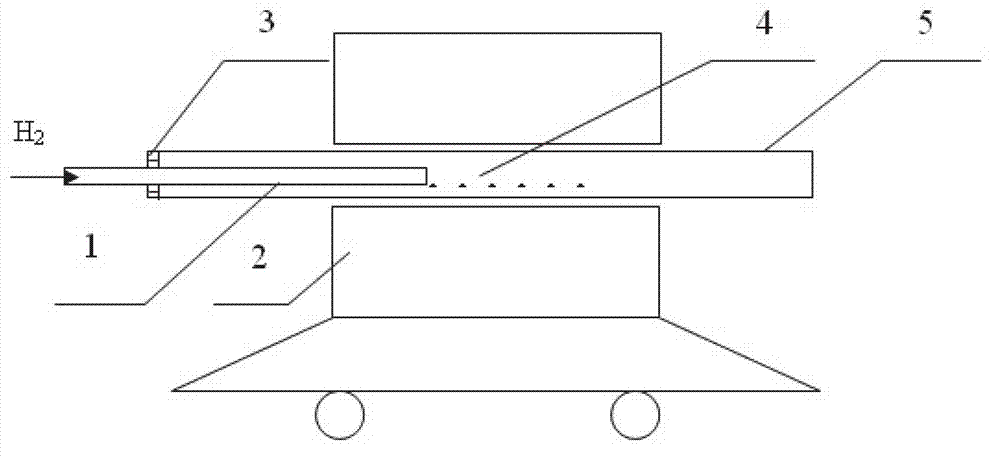

[0031] against figure 1 The main points of operation of the experimental preparation device shown in are as follows:

[0032] Distribute an appropriate amount of raw material calcium hydride powder (commercially available) in the middle section of the quartz reaction tube 5 and complete the system assembly;

[0033] In atmospheric air environment, switch on figure 2 Shown electrolyzer 7 (be used for preparation at first, be used for test afterwards), pass into the dry hydrogen flow that electrolyzes water and produce with it to stabilize;

[0034] 1. Start the horizontal tubular electric furnace 2 within a limited time to heat up quickly, the microcomputer adjusts and controls the temperature value of the hot spot, the timer controls the reaction time, and slowly cools down;

[0035] 2. Discharge after cooling, keep warm and dry, and measure.

[0036] Its reaction conditions are controlled as...

Embodiment 2

[0040] Embodiment 2. The second of the preparation experiment of active calcium hydride.

[0041] The experimental device and operating points are the same as in Example 1. The temperature of the hot spot is controlled at 300° C., the total reaction time is 10 hours, and the hydrogen flow rate is controlled to be 0.1 liter / hour per gram of calcium hydride converted.

[0042] Experimental results: The actual yield of active calcium hydride was 92%.

Embodiment 3

[0043] Example 3. Determination of negative hydrogen ion concentration in active calcium hydride hydrolyzate.

[0044] Determination method: DC electrolysis method.

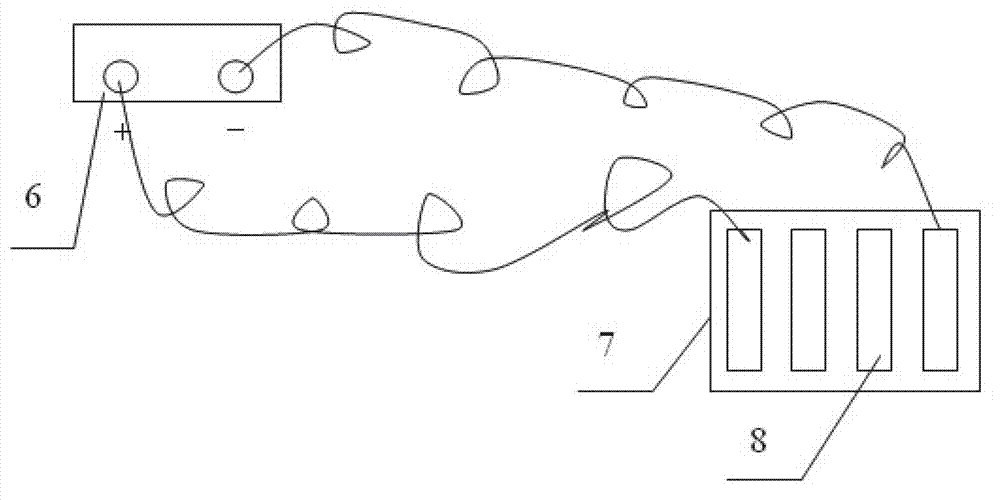

[0045] against figure 2 The experimental test device shown in , its equipment consists of:

[0046] 1. DC stabilized voltage and current power supply (commercially available).

[0047] 2. Electrolyzer 7: Self-made, composed of electrode 8 components, tank body and other related accessories. The tank body is a rectangular box-like container.

[0048] 3. The electrode 8 assembly is composed of 4 graphite electrode plates combined in a bipolar manner to form a three-chamber electrolytic cell in series.

[0049] The key points of its operation are:

[0050] 1. Adopt constant voltage control, set the total voltage to 6.0 volts, and the actual working voltage of each electrolytic chamber is about 2 volts.

[0051] 2. Get 120 grams of the active calcium hydride pattern that embodiment 1 makes, 1.5 liters of clean...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com