Method for recovering yttrium and europium in waste fluorescent powder to prepare yttrium europium oxide

A technology of yttrium europium oxide and fluorescent powder, which is applied in chemical instruments and methods, zinc sulfide, luminescent materials, etc., can solve the problems of high acid consumption and long reaction time, and achieve the effect of reducing acid consumption and recycling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

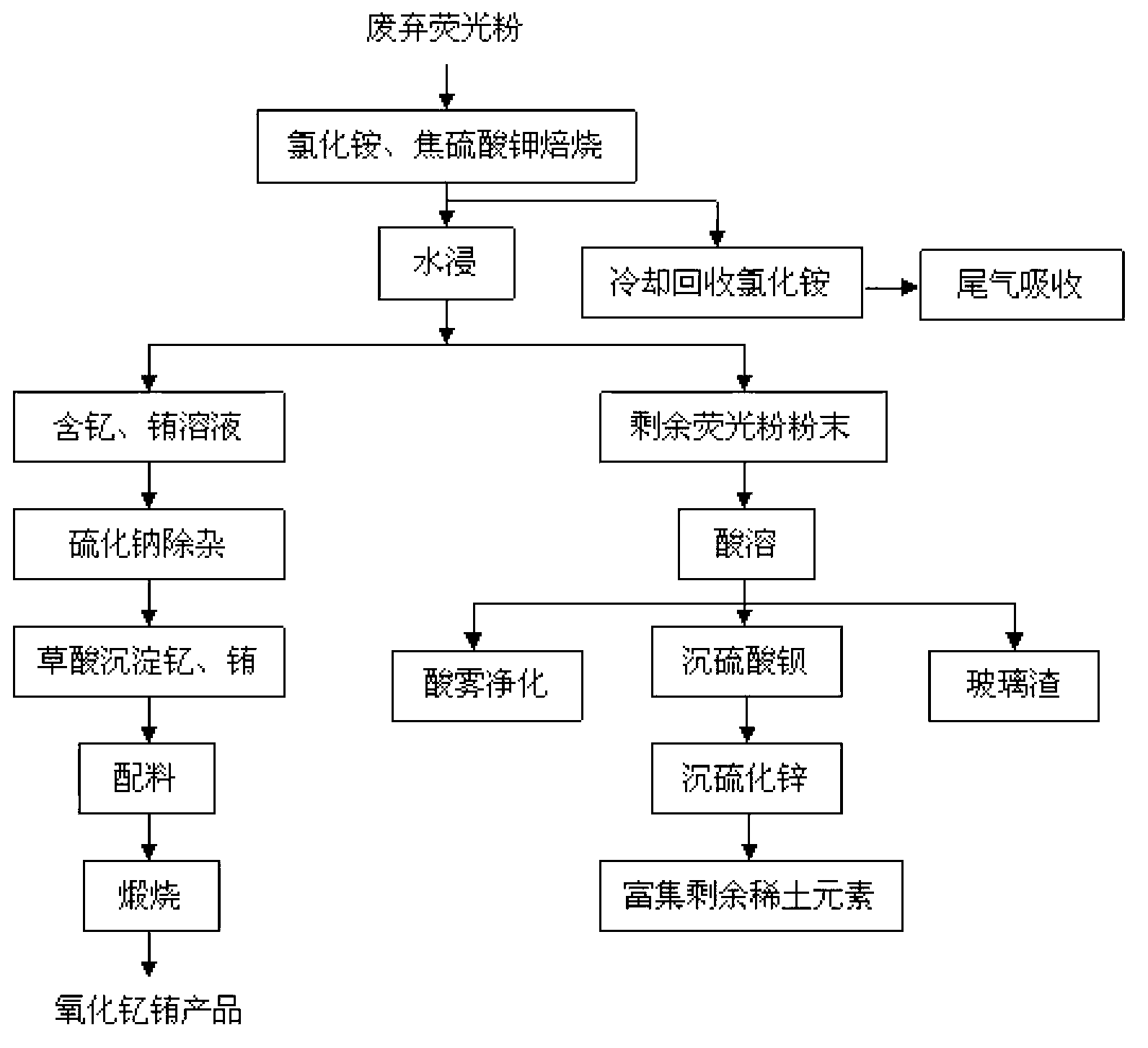

Method used

Image

Examples

Embodiment 1

[0044] a. Weigh 50.0 g of waste fluorescent powder, which contains 9.60 g of yttrium, 0.75 g of europium and 14.0 g of zinc by weight. Ammonium chloride and potassium pyrosulfate are mixed evenly with waste fluorescent powder in a powder mixer according to the mass ratio of waste phosphor: ammonium chloride: potassium pyrosulfate = 1:6:0.1, and then placed in a roasting furnace at 350°C Keep warm for 20 minutes to allow the fluorescent powder to fully react. The roasting furnace is heated up to 500° C., and then the reacted solid is put into the roasting furnace, and kept at 500° C. for 10 minutes.

[0045] b. Add deionized water according to the solid-to-liquid ratio of 1g:5ml, soak the solid after the final reaction in step a, and filter to obtain 18.30g of yttrium and europium-containing solution and undissolved phosphor powder.

[0046] c. Adjust the pH of the solution to 2.5, then add 3.11 g of sodium sulfide to remove a small amount of impurities such as iron, zinc, cad...

Embodiment 2

[0051] a. Weigh 75.0 g of waste fluorescent powder, which contains 14.25 g of yttrium, 1.16 g of europium and 21.75 g of zinc by weight. Ammonium chloride and potassium pyrosulfate are mixed evenly with waste fluorescent powder in a powder mixer according to the mass ratio of waste phosphor: ammonium chloride: potassium pyrosulfate=1:8:0.08, and then placed in a roasting furnace at 370°C Keep warm for 30 minutes to allow the fluorescent powder to fully react. The roasting furnace is heated up to 525° C., and then the reacted solid is put into the roasting furnace, and kept at 525° C. for 5 minutes.

[0052] b. Add deionized water according to the solid-to-liquid ratio of 1g: 15ml, soak the solid after the final reaction in step a, and filter to obtain 28.33g of yttrium and europium-containing solution and undissolved phosphor powder.

[0053] c. Adjust the pH of the solution to 2.2, then add 3.89 g of sodium sulfide to remove a small amount of impurities such as iron, zinc, c...

Embodiment 3

[0058] a. Weigh 100.0 g of waste fluorescent powder, which contains 23.15 g of yttrium, 1.23 g of europium and 11.38 g of zinc by weight. Ammonium chloride and potassium pyrosulfate are mixed evenly with waste fluorescent powder in a powder mixer according to the mass ratio of waste phosphor: ammonium chloride: potassium pyrosulfate = 1:10:0.1, and then placed in a roasting furnace at 390°C Keep warm for 45 minutes to allow the fluorescent powder to fully react. The roasting furnace is heated up to 550° C., and then the reacted solid is put into the roasting furnace, and kept at 550° C. for 5 minutes.

[0059] b. Add deionized water according to the solid-to-liquid ratio of 1g: 25ml, soak the solid after the final reaction in step a, and filter to obtain 19.89g of yttrium and europium-containing solution and undissolved phosphor powder.

[0060] c. Adjust the pH of the solution to 2.8, then add 6.17 g of sodium sulfide to remove a small amount of impurities such as iron, zinc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com